This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3078327 Leaf Spring is a component designed for use in commercial trucks. It serves a significant role in the suspension system, contributing to the overall performance and safety of the vehicle during operation. Understanding its function and importance can provide valuable insights into the maintenance and efficiency of commercial truck fleets.

Basic Concepts of Leaf Springs

Leaf springs are a type of suspension component commonly used in commercial vehicles. They consist of multiple layers of steel, known as leaves, which are stacked together and held in place by clamps. The primary function of a leaf spring is to support the weight of the vehicle and its load, absorb shocks from the road, and maintain the alignment of the wheels. In the context of commercial trucks, leaf springs play a vital role in ensuring a stable and comfortable ride, even under heavy loads 1.

Purpose of the Cummins 3078327 Leaf Spring

The Cummins 3078327 Leaf Spring is specifically engineered to enhance the suspension system of commercial trucks. It is designed to bear significant loads, providing support for the vehicle’s weight and contributing to the overall stability and handling. By effectively distributing the weight and absorbing road shocks, this leaf spring helps to maintain optimal contact between the tires and the road surface, which is crucial for safety and performance 2.

Key Features

The Cummins 3078327 Leaf Spring boasts several key features that enhance its performance. It is constructed from high-quality steel, ensuring durability and resistance to wear and tear. The design includes multiple leaves of varying lengths, which work together to provide flexibility and strength. Additionally, the spring is treated to resist corrosion, extending its lifespan in various operating conditions 3.

Benefits

The use of the Cummins 3078327 Leaf Spring in commercial trucks offers several benefits. It contributes to improved ride quality by effectively absorbing shocks and vibrations from the road. Its robust construction ensures durability, making it suitable for heavy-duty applications. Furthermore, the reliability of this leaf spring reduces the need for frequent replacements, offering cost savings over time 4.

Installation Considerations

Proper installation of the Cummins 3078327 Leaf Spring is crucial for optimal performance. It should be aligned correctly within the suspension system to ensure even weight distribution and proper function. Torque specifications provided by the manufacturer should be followed to secure the spring in place. Compatibility with other suspension components must also be considered to avoid issues such as misalignment or reduced effectiveness 5.

Maintenance and Troubleshooting

Routine maintenance of the Cummins 3078327 Leaf Spring is important for ensuring its longevity and performance. Regular inspections for signs of wear, corrosion, or damage are recommended. Lubricating the spring and its mounting points can help prevent friction-related issues. Troubleshooting common problems such as sagging, noise, or uneven wear may involve checking the alignment, inspecting for damage, and ensuring all components are securely fastened 6.

Performance in Various Conditions

The Cummins 3078327 Leaf Spring is designed to perform under a range of driving conditions. It can handle rough terrain, heavy loads, and varying temperatures without significant degradation in performance. Its ability to adapt to different conditions makes it a reliable choice for commercial truck operators who face diverse operational environments 7.

Comparison with Other Suspension Systems

When compared to alternative suspension systems, the Cummins 3078327 Leaf Spring offers a balance of cost, performance, and maintenance requirements. While air suspension systems may provide a smoother ride, they often require more complex maintenance and can be more expensive. Leaf springs, on the other hand, are simpler in design, more cost-effective, and generally easier to maintain, making them a popular choice for many commercial truck applications 8.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong reputation in the commercial truck industry, Cummins offers a wide range of products designed to meet the demanding requirements of heavy-duty applications. The company’s commitment to innovation, quality, and customer satisfaction has established it as a trusted name in the industry.

Leaf Spring Part 3078327 in Cummins Engines

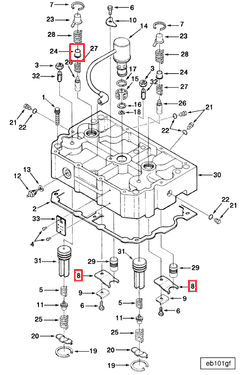

The Leaf Spring part 3078327, manufactured by Cummins, is a critical component in various Cummins engine models. This part is integral to the engine’s structural integrity and operational efficiency.

N14 MECHANICAL

In the N14 MECHANICAL engine, the Leaf Spring part 3078327 plays a pivotal role in maintaining the alignment and stability of the engine’s components. It ensures that the engine operates smoothly by absorbing shocks and vibrations, which are common in heavy-duty applications. This part is essential for the longevity and performance of the engine, as it helps in reducing wear and tear on other engine parts.

The Leaf Spring part 3078327 is designed to fit seamlessly within the engine’s framework, providing a robust connection between various components. Its placement is critical, as it must withstand the high stresses and dynamic forces encountered during engine operation. The precision engineering of this part ensures that it integrates perfectly with the engine’s design, contributing to overall engine reliability and efficiency.

Role of Part 3078327 Leaf Spring in Engine Systems

The part 3078327 Leaf Spring is an essential component that interfaces with various engine systems to ensure optimal performance and safety. Its primary function is to provide support and absorb shocks, which is vital for the smooth operation of the vehicle.

Interaction with Brake Systems

When integrated with brake systems, the Leaf Spring helps in maintaining the alignment and stability of the braking components. This ensures that the brake pads and rotors function efficiently, providing consistent stopping power. The Leaf Spring’s ability to absorb vibrations and shocks also prolongs the lifespan of the brake components by reducing wear and tear.

Integration with Engine and Control Systems

In engine systems, particularly those equipped with engine brakes, the Leaf Spring plays a significant role. It supports the engine mount, which is crucial for maintaining the engine’s position and reducing vibrations transmitted to the chassis. This is especially important in systems like the Cummins Engine Brake Kit, where precise engine placement is necessary for effective braking and overall performance.

Contribution to Engine Brake Kits

For engine brake kits, such as the Cummins Engine Brake Kit, the Leaf Spring ensures that the additional weight and forces generated by the engine brake are properly managed. It helps in distributing the load evenly across the suspension system, which is essential for maintaining vehicle stability during engine braking. This is particularly beneficial in heavy-duty applications where engine brakes are commonly used to assist in slowing down the vehicle.

Enhanced Performance in Control Systems

In control systems that manage engine functions, the Leaf Spring contributes to the overall stability and responsiveness of the vehicle. By providing a stable platform for the engine and related components, it allows the control systems to operate more effectively. This results in better handling, improved fuel efficiency, and enhanced driver comfort.

Conclusion

The Cummins 3078327 Leaf Spring is a versatile component that enhances the functionality and durability of various engine systems, including brakes, engine mounts, and control systems. Its role in absorbing shocks and maintaining component alignment is indispensable for the efficient operation of modern vehicles.

-

Hilgers, Michael. Chassis and Axles. Springer Vieweg, 2023.

↩ -

Calder, Nigel. Diesel Engine Care and Repair. The McGraw-Hill Companies, 2007.

↩ -

Hu, Haoran, Rudy Smaling, and Simon Baseley. Heavy-Duty Wheeled Vehicles. SAE International, 2014.

↩ -

Cummins Inc. General Information. Bulletin Number 4021315-00, Troubleshooting and Repair Manual.

↩ -

Cummins Inc. General Information. Bulletin Number 4021315-00, Troubleshooting and Repair Manual.

↩ -

Cummins Inc. General Information. Bulletin Number 4021315-00, Troubleshooting and Repair Manual.

↩ -

Cummins Inc. General Information. Bulletin Number 4021315-00, Troubleshooting and Repair Manual.

↩ -

Cummins Inc. General Information. Bulletin Number 4021315-00, Troubleshooting and Repair Manual.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.