This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3056358 Torsion Spring is a component designed for use in commercial trucks. Its purpose is to provide necessary tension and support within the truck’s mechanical systems, ensuring smooth operation and reliability. This spring is specifically engineered to meet the demanding requirements of heavy-duty applications, contributing to the overall performance and longevity of the vehicle 1.

Basic Concepts of Torsion Springs

Torsion springs are mechanical devices that store and release rotational energy. They function by twisting along their axis when a force is applied, and they return to their original position once the force is removed. These springs are commonly used in various mechanical systems to provide tension, support, and control movement. Their applications range from simple household items to complex industrial machinery, including automotive and heavy-duty truck components 2.

Purpose of the 3056358 Torsion Spring in Trucks

In commercial trucks, this part plays a specific role within the mechanical systems. It is primarily used to maintain tension and ensure proper function of certain components, such as valves or other moving parts. By providing consistent tension, this spring helps in the efficient operation of the truck’s engine and other systems, contributing to the vehicle’s overall performance and reliability 3.

Key Features

The Cummins 3056358 Torsion Spring is characterized by several key features that enhance its performance. It is made from high-quality materials, ensuring durability and resistance to wear and tear. The design specifications of this spring are tailored to meet the rigorous demands of commercial truck applications. Additionally, it may possess unique attributes such as corrosion resistance or specific load-bearing capacities that further improve its functionality in heavy-duty environments.

Benefits

The use of the 3056358 Torsion Spring in commercial trucks offers several benefits. Its high-quality construction contributes to improved durability, allowing it to withstand the stresses of heavy-duty use. The reliable performance of this spring ensures consistent operation of the truck’s mechanical systems, leading to increased efficiency. Furthermore, its design may include features that reduce maintenance requirements, providing cost savings over time.

Installation Process

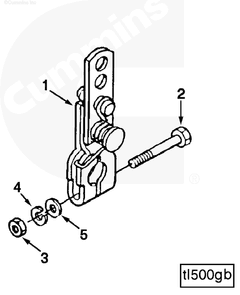

Proper installation of the 3056358 Torsion Spring is crucial for ensuring its effective function within the truck’s mechanical systems. The process involves several steps, including preparing the installation area, using the appropriate tools, and following safety precautions. Detailed instructions should be consulted to ensure correct placement and tensioning of the spring, which are vital for its performance and the safety of the vehicle.

Troubleshooting Common Issues

Common problems associated with the 3056358 Torsion Spring may include issues such as reduced tension, wear, or failure to function correctly. These problems can arise from various causes, including improper installation, excessive wear, or environmental factors. Recommended solutions may involve adjusting the spring, replacing worn components, or addressing environmental conditions that affect its performance.

Maintenance Tips

To ensure the longevity and optimal performance of the 3056358 Torsion Spring, regular maintenance is recommended. This includes periodic inspection for signs of wear or damage, ensuring proper tension, and following manufacturer guidelines for lubrication and care. Adhering to these maintenance practices can help prevent issues and extend the service life of the spring.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance components. The company’s product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of heavy-duty applications.

Cummins Engine Compatibility with Torsion Spring Part 3056358

The Torsion Spring part number 3056358, manufactured by Cummins, is a critical component in several engine models. This part is designed to provide essential functionality and reliability across a range of Cummins engines, ensuring smooth operation and durability.

K19 and K38 Engines

The K19 and K38 engines are part of Cummins’ lineup of medium-duty diesel engines. These engines are known for their robust performance and efficiency, making them suitable for various applications, including commercial vehicles and industrial machinery. The Torsion Spring part 3056358 is integral to these engines, providing necessary tension and support within the engine’s mechanisms. Its role is crucial in maintaining the integrity of the engine’s components, ensuring that the engine operates smoothly and efficiently.

K50 Engines

The K50 engine is another medium-duty diesel engine from Cummins, designed for heavy-duty applications. This engine is built to deliver high power output and reliability, making it a preferred choice for industries that require robust and dependable machinery. The Torsion Spring part 3056358 is a key component in the K50 engine, contributing to the engine’s overall performance by maintaining the correct tension in various parts. Its precision engineering ensures that the engine can withstand the rigors of heavy-duty use, providing long-lasting performance.

KTA38GC CM558 Engines

The KTA38GC CM558 engine is a high-performance diesel engine designed for demanding applications. This engine is part of Cummins’ advanced engine series, offering superior power and efficiency. The Torsion Spring part 3056358 is essential in the KTA38GC CM558 engine, providing the necessary tension and support to various engine components. Its design and precision engineering ensure that the engine can handle high loads and operate under extreme conditions, making it ideal for applications that require maximum reliability and performance.

Each of these engines benefits from the Torsion Spring part 3056358, which is engineered to meet the specific needs of Cummins’ engine designs. This part’s compatibility across different engine models highlights its versatility and importance in ensuring the smooth and efficient operation of Cummins engines.

Role of Part 3056358 Torsion Spring in Engine Systems

Part 3056358 Torsion Spring is integral to the functionality of several components within engine systems. Its primary role is to provide the necessary tension and return force for various mechanical parts, ensuring smooth and precise operation.

Lever and Rocker Mechanisms

In lever and rocker mechanisms, the torsion spring ensures that these components return to their neutral position after being actuated. This is particularly important in systems where consistent and reliable movement is required. The spring’s tension helps maintain the balance and responsiveness of the lever and rocker, contributing to the overall efficiency of the engine’s operation.

Throttle and Throttle Lever

For the throttle and throttle lever, part 3056358 Torsion Spring plays a significant role in maintaining the correct tension. When the throttle is engaged, the spring provides the necessary force to return the lever to its default position once released. This ensures that the throttle responds accurately to driver inputs, which is essential for maintaining control and performance of the engine. The spring’s design allows for precise modulation of the throttle, enhancing the driver’s ability to manage engine speed and power output effectively.

Conclusion

The Cummins 3056358 Torsion Spring is a vital component in commercial trucks and Cummins engines, providing essential tension and support to various mechanical systems. Its high-quality construction, precise engineering, and compatibility across different engine models make it a reliable and efficient part. Proper installation, regular maintenance, and understanding its role within engine systems are crucial for ensuring the longevity and optimal performance of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.