3050388

Leaf Spring

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3050388 Leaf Spring is a component designed for use in heavy-duty truck suspension systems. It serves to support the vehicle’s weight, absorb shocks from the road, and contribute to maintaining ride quality. Understanding its role and significance is key to appreciating its function within the broader context of truck suspension technology.

Basic Concepts of Leaf Springs

Leaf springs are a type of suspension spring made from multiple layers, or leaves, of spring steel. They function by flexing under load to absorb shocks and maintain wheel contact with the road. Historically, leaf springs have been widely used in the automotive industry due to their simplicity, durability, and effectiveness in supporting heavy loads 1.

Purpose of the 3050388 Leaf Spring

This part plays a role in the operation of a truck by supporting the vehicle’s weight, absorbing shocks from the road surface, and helping to maintain ride quality. It is engineered to handle the stresses and strains associated with heavy-duty truck operations, ensuring stability and comfort under various driving conditions.

Key Features

The Cummins 3050388 Leaf Spring is characterized by its specific design and construction features. These include a material composition that enhances strength and durability, a layering system that allows for flexibility and shock absorption, and unique attributes that improve its performance under heavy loads. These features contribute to its effectiveness in heavy-duty applications.

Benefits

The advantages of the 3050388 Leaf Spring include an improved load-carrying capacity, enhanced durability under heavy-duty conditions, and potential cost savings over the lifespan of the truck. Its design allows for efficient weight distribution and shock absorption, contributing to a smoother ride and reduced wear on other suspension components.

Installation and Compatibility

Proper installation of the 3050388 Leaf Spring involves following specific procedures to ensure it is correctly positioned and secured within the truck’s suspension system. This may include preparations or adjustments to the vehicle to accommodate the spring. Compatibility with various truck models and configurations is an important consideration for ensuring optimal performance.

Troubleshooting and Maintenance

Common issues with leaf springs, such as sagging, noise, or uneven wear, can often be identified through regular inspection and maintenance. Recommended practices include checking for signs of wear or damage, ensuring proper alignment, and addressing any issues promptly to maintain optimal performance and longevity of the spring.

Performance and Testing

The 3050388 Leaf Spring undergoes testing for performance and durability to meet industry standards and Cummins-specific protocols. These tests evaluate its ability to withstand heavy loads, resist fatigue, and maintain functionality over time, ensuring quality and reliability in heavy-duty truck applications.

Environmental and Operational Considerations

Different environmental conditions and operational factors, such as terrain, load types, and driving habits, can affect the performance and lifespan of the 3050388 Leaf Spring. Understanding these influences is important for maintaining the spring’s effectiveness and ensuring it continues to provide reliable support and shock absorption.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins serves a wide range of industries, including automotive and heavy-duty truck manufacturing, with a diverse product range that includes components like the 3050388 Leaf Spring.

Compatibility with N14 Engines

This Cummins part is designed to be compatible with various configurations of the N14 engine series. It is integral to the engine’s mounting and vibration management systems, ensuring that the engine remains securely fastened while also mitigating the impact of operational vibrations.

N14 CELECT Engine

In the N14 CELECT engine, the Leaf Spring plays a role in maintaining the alignment and stability of the engine. Given the electronic control unit (ECU) management in the CELECT variant, this part ensures that the engine’s mounting system can handle the precise control and feedback mechanisms inherent to this engine type.

N14 MECHANICAL Engine

For the N14 MECHANICAL engine, the Leaf Spring is equally important. This variant relies on mechanical controls rather than electronic ones, making the robust design of the leaf spring essential for managing the engine’s physical stresses and vibrations. The spring’s design helps to absorb and distribute the forces exerted during engine operation, contributing to the longevity and reliability of the engine.

Grouping Considerations

While the Leaf Spring is compatible with both the N14 CELECT and N14 MECHANICAL engines, it is important to consider the specific operational environment and usage patterns of each engine type. The CELECT variant’s electronic controls may require a slightly different tuning of the leaf spring to accommodate the feedback systems, whereas the MECHANICAL variant’s reliance on physical mounts and controls necessitates a focus on durability and strength.

By ensuring that the Leaf Spring is correctly installed and maintained, operators can enhance the performance and lifespan of their N14 engines, regardless of whether they are operating in CELECT or MECHANICAL configurations.

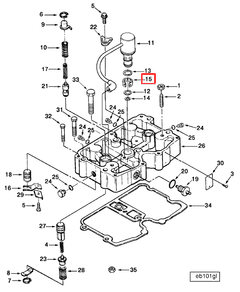

Role of 3050388 Leaf Spring in Engine Systems

This part is an integral component in various engine systems, particularly those involving braking mechanisms. In the context of a Brake system, the Leaf Spring works in conjunction with the Brake components to ensure efficient and reliable stopping power. It helps in maintaining the structural integrity and alignment of the brake assembly, which is essential for consistent brake performance.

When integrated into an Engine Brake system, the Leaf Spring assists in managing the forces generated during engine braking. This is particularly relevant in systems like the Cummins Engine Brake, where the spring’s flexibility and strength are utilized to absorb and distribute the stresses imposed on the brake components.

In a Cummins Engine Brake Kit or an Engine Brake Overhaul Kit, the Leaf Spring plays a supportive role. It ensures that the brake components remain in optimal condition and function as intended under varying load conditions. The spring’s design allows it to adapt to the dynamic forces within the engine brake system, contributing to the overall effectiveness and longevity of the brake components.

Furthermore, in an Engine Brake Kit, the Leaf Spring is instrumental in enhancing the durability and performance of the brake system. It helps in maintaining the precise alignment of brake components, which is vital for the efficient operation of the engine brake. This is especially important in high-stress environments where the engine brake is frequently engaged.

Conclusion

In summary, the 3050388 Leaf Spring is a key element in various engine and brake systems. Its role in supporting and aligning brake components, absorbing dynamic forces, and contributing to the overall performance and durability of the brake system is significant.

-

Lakshminarayanan, P A, and Yogesh V Aghav. Modelling Diesel Combustion. Springer Science, 2010.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.