This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

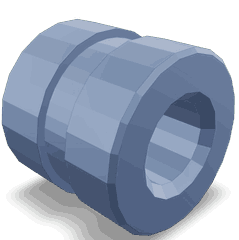

The Idle Spring Plunger, identified by part number 140417, is a component manufactured by Cummins, a prominent name in engine manufacturing. This Cummins part is integral to the operation of heavy-duty truck engines, contributing to their efficiency and reliability. Cummins, known for its innovation and quality in the automotive industry, ensures that this component meets the rigorous demands of heavy-duty applications 1.

Function and Operation

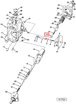

The Idle Spring Plunger operates within the engine system by interacting with various components to regulate engine performance during idling. It works in conjunction with the fuel injection system and idle control mechanisms. The plunger’s movement is controlled by a spring, which adjusts the fuel delivery to the engine, ensuring smooth operation at low speeds. This interaction helps maintain consistent engine RPMs and reduces fluctuations that could lead to inefficient fuel consumption or engine strain 2.

Purpose of the Idle Spring Plunger

The primary role of the Idle Spring Plunger is to contribute to the smooth and efficient operation of a truck engine during idling. By regulating fuel delivery, it helps achieve optimal fuel efficiency and ensures a stable engine performance. This is particularly important in heavy-duty trucks, where idling can occur frequently, such as during loading and unloading operations or when stationary in traffic 3.

Key Features

The Idle Spring Plunger is designed with several key features that enhance its functionality. It is typically made from durable materials to withstand the high pressures and temperatures within the engine. The design includes precision-machined components to ensure accurate movement and reliable performance. Additionally, the spring mechanism is calibrated to provide the necessary force for optimal fuel regulation.

Benefits

The Idle Spring Plunger offers several advantages. It contributes to improved engine performance by ensuring consistent fuel delivery during idling, which can lead to better fuel efficiency. Reduced wear on engine components is another benefit, as stable idling conditions minimize stress on the engine. Fleet operators may also experience cost savings due to the part’s role in enhancing fuel efficiency and reducing maintenance needs.

Troubleshooting and Maintenance

Common issues with the Idle Spring Plunger may include wear or damage to the spring mechanism, leading to inconsistent idling. Regular maintenance practices, such as inspecting the plunger for signs of wear and ensuring the spring is functioning correctly, can help prevent these issues. If replacement or repair is necessary, it is important to follow manufacturer guidelines to ensure proper installation and continued engine performance.

Integration within the Engine System

The Idle Spring Plunger interacts with other engine components, such as the fuel injection system and idle control mechanisms, to contribute to overall engine efficiency and reliability. Its role in regulating fuel delivery during idling ensures that the engine operates smoothly and efficiently, even under low-load conditions. This integration is vital for maintaining the engine’s performance across a range of operating conditions.

Historical Development

The evolution of Idle Spring Plungers in heavy-duty truck engines has seen advancements in design and technology that have enhanced their performance and durability. Early versions of these components were simpler in design, but modern iterations incorporate precision engineering and high-quality materials to meet the demands of contemporary heavy-duty applications. These advancements have led to more reliable and efficient engine operation.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a trusted name in the automotive industry. The company is committed to innovation, quality, and customer satisfaction, ensuring that its products, including the Idle Spring Plunger, meet the highest standards of performance and reliability.

Role of Part 140417 Idle Spring Plunger in Engine Systems

The Idle Spring Plunger, part 140417, is an integral component in the orchestration of various engine systems, ensuring smooth and efficient operation. Its primary function is to maintain the stability of the idle speed by interacting with several key components.

Interaction with Calibration and Fuel Systems

The Idle Spring Plunger works in conjunction with the engine’s calibration settings. Proper calibration ensures that the engine operates within optimal parameters, and the plunger helps in fine-tuning the idle speed to match these settings.

In fuel systems, the plunger interacts with the fuel pump and its associated codes (such as CPL 161, CPL 162, CPL 187, CPL 196, CPL 217, CPL 22, CPL-101, CPL-11, and CPL-163). It assists in maintaining a consistent fuel supply, which is essential for stable idle conditions. The fuel pump code and fuel base settings are adjusted to ensure that the fuel delivery matches the engine’s requirements during idle, with the plunger playing a supportive role in this process.

Fuel Code and Pump Code Integration

The fuel code and pump code are critical for the engine’s performance, and the Idle Spring Plunger aids in their effective implementation. By ensuring that the idle speed remains consistent, the plunger allows the fuel code to deliver the correct amount of fuel, preventing issues such as stalling or rough idling.

Similarly, the pump code, which dictates how the fuel pump operates, benefits from the stable idle speed maintained by the plunger. This stability ensures that the fuel pump can deliver fuel efficiently, without the need for constant adjustments.

Overall Engine Stability

In summary, the Idle Spring Plunger, part 140417, enhances the overall stability and performance of the engine by interacting with calibration settings, fuel systems, and pump codes. Its role in maintaining a consistent idle speed is essential for the efficient operation of these interconnected systems.

Conclusion

The Idle Spring Plunger, part 140417, is a vital component in Cummins engines, contributing to their efficiency, reliability, and smooth operation. Its role in regulating fuel delivery during idling, interacting with calibration and fuel systems, and maintaining overall engine stability underscores its importance in heavy-duty truck engines. Regular maintenance and proper installation are key to ensuring the continued performance and longevity of this part.

-

Goodnight, N., & VanGelder, K. (2019). Automotive Braking Systems CDX Master Automotive Technician Series. Jones Bartlett Learning.

↩ -

Berns, K., Dressler, K., Fleischmann, P., Grges, D., Kalmar, R., Sauer, B., Stephan, N., Teutsch, R., & Thul, M. (2018). Proceedings of the 5th Commercial Vehicle Technology Symposium CVT. Springer.

↩ -

Lejda, K., & Wos, P. (2012). Internal Combustion Engines. InTech.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.