This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 122886 Torsion Spring is a component designed for use in commercial trucks. It serves a specific function within the truck’s mechanical system, contributing to the overall operation and performance of the vehicle. Understanding its purpose and significance is important for maintaining and optimizing truck performance.

Basic Concepts of Torsion Springs

Torsion springs are mechanical devices that store and release rotational force. They operate by twisting along their axis when a force is applied, and they return to their original shape when the force is removed. These springs are commonly used in various mechanical systems to provide torque, maintain tension, or store energy. Their applications range from simple mechanisms like door hinges to complex systems in automotive and industrial machinery 1.

Role of the 122886 Torsion Spring in Truck Operation

This Cummins part plays a role in the mechanical system of commercial trucks by providing necessary tension and rotational force. It is involved in the operation of certain truck components, ensuring they function correctly under various conditions. The spring’s ability to twist and return to its original shape allows it to perform its function effectively within the truck’s system 2.

Key Features of the 122886 Torsion Spring

The 122886 is characterized by its specific design and material composition. It is crafted from high-quality materials to ensure durability and reliability. The spring’s design allows it to withstand the stresses and strains of truck operation, while its material composition contributes to its longevity and performance. Unique characteristics of the spring may include its size, shape, and the precision with which it is manufactured, all of which enhance its functionality in truck applications 3.

Benefits of Using the 122886 Torsion Spring

Using this part in commercial trucks can lead to improved efficiency, durability, and reliability. Its design and material composition allow it to perform effectively under the demanding conditions of truck operation. The spring’s ability to maintain tension and provide rotational force contributes to the smooth and efficient operation of the truck’s mechanical system 4.

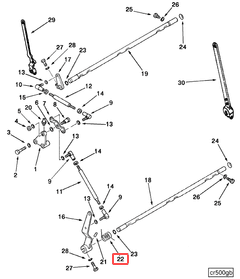

Installation and Integration

Proper installation and integration of this Cummins part within a truck’s mechanical system are important for ensuring its effective operation. Guidelines for installation may include specific procedures for mounting the spring, connecting it to other components, and ensuring it is properly aligned and secured. Careful attention to these details helps to ensure the spring functions as intended within the truck’s system.

Maintenance and Troubleshooting

Maintaining the 122886 involves regular inspection routines to check for signs of wear, damage, or misalignment. Common issues to watch for may include changes in the spring’s tension, visible signs of wear or corrosion, and any unusual noises or vibrations during operation. Troubleshooting tips may include checking for proper alignment, ensuring the spring is securely mounted, and addressing any signs of wear or damage promptly to prevent further issues.

Performance and Longevity

The performance and longevity of the 122886 are influenced by various factors, including operating conditions, maintenance practices, and potential wear and tear. Regular maintenance and proper installation contribute to the spring’s durability and reliability. Operating conditions, such as exposure to extreme temperatures or heavy loads, may also affect the spring’s performance and lifespan.

Cummins: A Brief Overview

Cummins Inc. is a company with a history of innovation and quality in the automotive industry, particularly in diesel engines and technologies. The company’s expertise and commitment to innovation are reflected in its products, including the 122886. Cummins’ focus on quality and performance ensures that its components meet the demanding requirements of commercial truck operation.

Conclusion

The Cummins 122886 Torsion Spring is a vital component in the mechanical system of commercial trucks, contributing to their efficiency, durability, and reliability. Its design, material composition, and proper installation and maintenance are key to ensuring optimal performance and longevity. Cummins’ reputation for quality and innovation underscores the importance of this part in meeting the demanding requirements of truck operation.

-

Boyce, M. P. (2011). Gas Turbine Engineering Handbook (4th ed.). Butterworth-Heinemann.

↩ -

Gilles, T. (2020). Automotive Service: Inspection, Maintenance, Repair (2nd ed.). Cengage Learning.

↩ -

Lejda, K., & Wos, P. (2012). Internal Combustion Engines. InTech.

↩ -

Mananathan, R. (2022). Automobile Wheel Alignment and Wheel Balancing. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.