This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4001381 Spline Coupling Sleeve, manufactured by Cummins, is a component designed for use in heavy-duty truck operations. Cummins, a well-established name in the automotive industry, produces this coupling sleeve to enhance the efficiency and reliability of truck drivetrains. This component is integral to the smooth operation of heavy-duty trucks, ensuring that power transmission is consistent and reliable under demanding conditions.

Basic Concepts of Spline Coupling Sleeves

A Spline Coupling Sleeve is a mechanical component used to connect two shafts, allowing them to rotate together while accommodating some degree of misalignment. In the context of a truck’s drivetrain, the spline coupling sleeve facilitates the transfer of torque from the engine to the wheels, ensuring that power is delivered efficiently and smoothly. The design of the spline coupling sleeve, with its interlocking teeth, allows for a secure connection that can withstand significant forces and vibrations 1.

Purpose of the 4001381 Spline Coupling Sleeve

The 4001381 Spline Coupling Sleeve plays a specific role in the operation of a truck by transmitting torque between the engine and the transmission. It is designed to accommodate minor misalignments that may occur between connected components, which is common in the dynamic environment of a truck’s drivetrain. This function is vital for maintaining the integrity of the power transmission path and ensuring that the truck operates efficiently 2.

Key Features

The 4001381 Spline Coupling Sleeve is characterized by several key features that enhance its performance and durability. Its design includes precision-machined splines that ensure a secure fit and efficient torque transmission. The material composition, typically a high-strength alloy, provides the necessary durability to withstand the rigors of heavy-duty truck operations. Additionally, the coupling sleeve may feature lubrication grooves or other design elements to reduce friction and wear, further enhancing its longevity 3.

Benefits

The advantages of using the 4001381 Spline Coupling Sleeve include improved efficiency in torque transmission, reduced wear on connected components, and enhanced overall performance of the truck’s drivetrain. By accommodating misalignments, the coupling sleeve helps to prevent stress concentrations that could lead to premature failure of drivetrain components. Furthermore, its durable construction and design features contribute to a longer service life, reducing the need for frequent replacements.

Installation Considerations

Proper installation of the 4001381 Spline Coupling Sleeve is crucial for ensuring optimal performance and longevity. Guidelines for installation include verifying that the mating surfaces are clean and free of debris, using the correct tools to avoid damage to the splines, and following the manufacturer’s torque specifications for any fastening components. Careful attention to these details during installation will help to ensure that the coupling sleeve functions as intended and contributes to the reliable operation of the truck.

Troubleshooting and Maintenance

Common issues that may arise with the 4001381 Spline Coupling Sleeve include wear on the splines, misalignment due to improper installation, or damage from excessive torque. Troubleshooting steps may involve inspecting the coupling sleeve for signs of wear or damage, checking the alignment of connected components, and ensuring that the coupling sleeve is properly lubricated. Regular maintenance practices, such as periodic inspection and lubrication, can help to prolong the component’s lifespan and prevent unexpected failures.

Cummins: Manufacturer Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong reputation in the automotive industry, Cummins is committed to producing high-quality components for heavy-duty trucks. The company’s focus on innovation, quality, and customer satisfaction has established it as a trusted name in the production of automotive and industrial components.

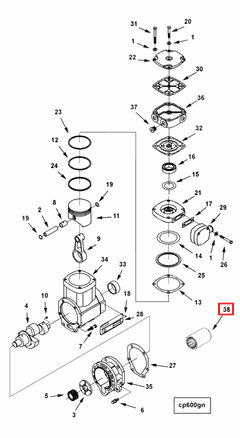

Spline Coupling Sleeve (Part 4001381) in Cummins Engines

The Spline Coupling Sleeve, identified by the part number 4001381, is a critical component in the Cummins QSK45 CM500 and QSK60 CM500 engines. This part is integral to the proper functioning of the engine’s power transmission system, ensuring that the torque generated by the engine is efficiently transferred to the driven components.

In the Cummins QSK45 CM500 and QSK60 CM500 engines, the Spline Coupling Sleeve is designed to connect the engine’s crankshaft to the transmission or other driven machinery. The splines on the sleeve engage with corresponding splines on the connected component, creating a secure and rigid connection that can withstand the high torque and rotational forces typical of these engines.

The design of the Spline Coupling Sleeve in these engines emphasizes durability and reliability. It is manufactured from high-strength materials that can endure the demanding conditions of heavy-duty operations. The precision engineering of the splines ensures a perfect fit, minimizing the risk of slippage or misalignment, which could lead to mechanical failures or reduced efficiency.

For maintenance and repair purposes, the Spline Coupling Sleeve is a component that requires careful handling and precise installation. Any misalignment or damage to the splines can compromise the integrity of the power transmission system, potentially leading to catastrophic engine failure. Therefore, technicians working with these engines must be well-versed in the proper procedures for inspecting, replacing, and aligning the Spline Coupling Sleeve to ensure the longevity and performance of the engine.

Role of Part 4001381 Spline Coupling Sleeve in Engine Systems

The 4001381 Spline Coupling Sleeve is an integral component in the synchronization and efficient operation of various engine systems, particularly in the context of compressor and air systems.

Compressor Systems

In compressor systems, the 4001381 Spline Coupling Sleeve facilitates the smooth transfer of rotational force from the engine to the compressor. This ensures that the compressor operates at optimal efficiency, maintaining consistent air pressure and flow. The coupling sleeve’s design allows for minor misalignments between the engine and compressor, which is common due to thermal expansion and mechanical tolerances. This adaptability helps in reducing wear and tear on both the engine and compressor, leading to prolonged operational life and reliability.

Air Systems

Within air systems, the 4001381 Spline Coupling Sleeve plays a significant role in maintaining the integrity of the air delivery mechanism. It connects various components such as the turbocharger and intercooler, ensuring that air is compressed and delivered efficiently to the engine’s intake system. The sleeve’s splined design provides a secure yet flexible connection, accommodating the dynamic movements and vibrations inherent in high-performance engines. This results in a stable air supply, which is essential for consistent engine performance and power output.

By integrating the 4001381 Spline Coupling Sleeve into these systems, engineers and mechanics can achieve enhanced performance, reliability, and efficiency in engine operations.

Conclusion

The 4001381 Spline Coupling Sleeve is a critical component in the efficient and reliable operation of heavy-duty truck drivetrains and engine systems. Its design, characterized by precision-machined splines and high-strength materials, ensures secure and efficient torque transmission. Proper installation and maintenance are essential to maximize its performance and longevity. Cummins’ commitment to quality and innovation in manufacturing this part underscores its importance in the automotive industry.

-

Taghavifar, H., & Mardani, A. (2017). Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer.

↩ -

Garrett, T. K., Newton, K., & Steeds, W. (2001). The Motor Vehicle. Reed Educational and Professional Publishing Ltd.

↩ -

Robert Bosch GmbH. (2007). Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition. Springer Vieweg.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.