3094212

Spline Coupling Sleeve

Cummins®

AVAILABLE

4 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

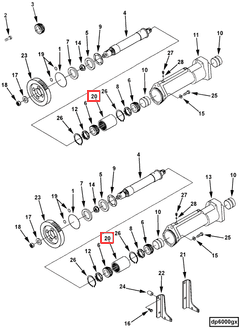

The Spline Coupling Sleeve, part number 3094212, manufactured by Cummins, is a component designed for use in heavy-duty truck operations. Cummins, a well-established name in the commercial truck industry, produces this part to meet the demanding requirements of truck mechanics and operators. This Cummins part is integral to the efficient and reliable operation of heavy-duty trucks, facilitating the transmission of torque and accommodating misalignment between components.

Basic Concepts of Spline Coupling Sleeves

A Spline Coupling Sleeve is a mechanical device used to connect two shafts that need to transmit torque while allowing for some degree of angular misalignment. In the context of heavy-duty trucks, these sleeves are crucial for maintaining the integrity of power transmission between various components, such as the engine and transmission, or between different sections of the drivetrain. The splines, which are ridges or teeth on the shaft and sleeve, engage to transmit torque while the sleeve’s design allows for slight misalignment, which can occur due to thermal expansion, wear, or manufacturing tolerances 1.

Purpose of the 3094212 Spline Coupling Sleeve

The 3094212 Spline Coupling Sleeve plays a specific role in the operation of a truck by transmitting torque between components that may not be perfectly aligned. This part ensures that power is efficiently transferred from the engine to the transmission and other drivetrain components, even when there is some degree of misalignment. Its function is vital for the smooth operation of the truck, reducing stress on connected components and enhancing the overall reliability of the drivetrain system.

Key Features

The 3094212 Spline Coupling Sleeve is characterized by several key features that enhance its performance and durability. Its design includes precision-machined splines that ensure a secure fit and efficient torque transmission. The material composition, typically a durable alloy, provides resistance to wear and corrosion, ensuring longevity in harsh operating conditions. Additionally, the sleeve may feature unique attributes such as a protective coating or specialized lubrication to further enhance its performance.

Benefits

The advantages provided by the 3094212 Spline Coupling Sleeve include improved efficiency in torque transmission, reduced wear on connected components due to its ability to accommodate misalignment, and enhanced reliability in truck operations. By ensuring smooth and efficient power transfer, this part contributes to the overall performance and durability of the truck’s drivetrain system.

Installation and Integration

Proper installation of the 3094212 Spline Coupling Sleeve involves several steps to ensure it functions correctly within the truck’s drivetrain system. Preparatory steps may include cleaning the mating surfaces and inspecting the shafts for damage or wear. Tools required for installation might include torque wrenches and alignment tools to ensure the sleeve is properly positioned and secured. Integration with other truck components requires careful attention to ensure that all connections are secure and that the sleeve is correctly aligned with the shafts it connects.

Troubleshooting Common Issues

Typical problems that may arise with the 3094212 Spline Coupling Sleeve include wear, misalignment, or failure due to excessive torque or contamination. Diagnostic steps may involve inspecting the sleeve for signs of wear or damage, checking alignment between connected components, and ensuring that the sleeve is properly lubricated. Solutions might include cleaning and re-lubricating the sleeve, realigning components, or replacing the sleeve if it is damaged beyond repair.

Maintenance Practices

Recommended maintenance routines for the 3094212 Spline Coupling Sleeve include regular inspection intervals to check for signs of wear or damage, cleaning procedures to remove contaminants that could affect performance, and lubrication to ensure smooth operation. When considering replacement, factors such as the extent of wear, frequency of use, and operating conditions should be taken into account to determine the appropriate time for replacement.

Cummins: Manufacturer Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and reliability in the commercial truck industry. The company’s product range includes a variety of components and systems designed to meet the demanding requirements of heavy-duty truck operations, ensuring that parts like the 3094212 Spline Coupling Sleeve are built to withstand the rigors of daily use in commercial applications.

Cummins Spline Coupling Sleeve 3094212 Compatibility

The Cummins Spline Coupling Sleeve part number 3094212 is a critical component designed to ensure seamless power transmission between the engine and other drivetrain components. This part is engineered to fit precisely with several Cummins engine models, ensuring reliable operation and durability.

QST30 CM552 Engines

The 3094212 Spline Coupling Sleeve is specifically designed to interface with the QST30 CM552 engines. This coupling sleeve plays a pivotal role in maintaining the integrity of the power transfer mechanism, ensuring that the rotational force from the engine is efficiently transmitted to the drivetrain components. The precision engineering of this part guarantees a snug fit, minimizing wear and tear and enhancing the overall performance of the engine.

Group Compatibility

While the 3094212 Spline Coupling Sleeve is primarily associated with the QST30 CM552 engines, it is also compatible with other Cummins engine models within the same group. This compatibility ensures that the sleeve can be used across multiple engine types, providing a versatile solution for various applications. The design and specifications of the 3094212 are meticulously crafted to meet the demands of these engines, ensuring optimal performance and longevity.

The Spline Coupling Sleeve 3094212 is a testament to Cummins’ commitment to quality and precision engineering, providing a reliable solution for power transmission in a variety of engine configurations.

Role of Part 3094212 Spline Coupling Sleeve in Engine Systems

The 3094212 Spline Coupling Sleeve is an integral component in the efficient operation of various engine systems. It facilitates the smooth transfer of rotational force between different parts, ensuring seamless functionality.

Integration with the Drive System

In the drive system, the Spline Coupling Sleeve connects the driveshaft to the transmission. This connection allows for the transfer of power from the engine to the wheels, enabling the vehicle to move. The splined design ensures a secure fit, minimizing slippage and maximizing torque transmission.

Function in the Fuel Pump System

Within the fuel pump system, the Spline Coupling Sleeve plays a role in connecting the fuel pump to the engine. This connection is vital for the consistent delivery of fuel to the combustion chambers. The sleeve’s precise fit ensures that the fuel pump operates efficiently, maintaining the correct fuel pressure and flow rate.

Role in the Socket System

In socket systems, particularly those used for maintenance and repair, the Spline Coupling Sleeve can be employed to connect various tools and components. This application ensures that sockets fit securely onto bolts and nuts, providing the necessary torque for tightening or loosening without the risk of slippage. The spline design enhances the grip, making the socket system more reliable and effective.

Conclusion

The 3094212 Spline Coupling Sleeve is a critical component in the operation of heavy-duty trucks, ensuring efficient torque transmission and accommodating misalignment between components. Its precision-machined splines, durable alloy composition, and specialized features contribute to its performance and longevity in harsh operating conditions. Proper installation, maintenance, and troubleshooting are essential for maximizing the benefits of this part, ensuring the smooth and reliable operation of the truck’s drivetrain system.

-

Automotive Emissions Regulations and Exhaust Aftertreatment Systems, John Kasab and Andrea Strzelec, SAE International, 2020.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.