This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 200824 Spline Coupling Sleeve is a critical component in heavy-duty truck applications, designed to enhance the efficiency and reliability of the vehicle’s mechanical system. Understanding its purpose and significance is essential for maintaining the performance of heavy-duty trucks.

Basic Concepts of Spline Coupling Sleeves

A Spline Coupling Sleeve is a mechanical component that connects two shafts, allowing them to rotate as a single unit while accommodating minor misalignments. It consists of ridges (splines) that fit into corresponding grooves on the shafts, ensuring a secure and efficient transfer of torque. In the automotive industry, these sleeves are used in various applications, including transmission systems, to ensure smooth power delivery from the engine to the wheels 1.

Role of the 200824 Spline Coupling Sleeve in Truck Operation

The 200824 Spline Coupling Sleeve is integral to the operation of heavy-duty trucks. It facilitates the connection between the transmission and the driveshaft, enabling the efficient transfer of power generated by the engine to the wheels. This component interacts with other parts of the drivetrain, contributing to the truck’s overall performance by ensuring consistent and reliable power transmission. Its design allows for flexibility in accommodating the natural movements and vibrations of the truck’s chassis, which is crucial for maintaining operational efficiency under varying load conditions 2.

Key Features

The 200824 Spline Coupling Sleeve is characterized by several key features that enhance its functionality. It is constructed from high-strength materials, ensuring durability under the demanding conditions of heavy-duty truck operation. The design specifications of this sleeve include precise spline geometry, which is critical for a secure fit and efficient torque transfer. Additionally, it may feature unique attributes such as corrosion-resistant coatings or enhanced lubrication systems to further improve its performance and longevity 3.

Benefits of Using the 200824 Spline Coupling Sleeve

Incorporating the 200824 Spline Coupling Sleeve into a truck’s drivetrain offers several advantages. Its robust construction contributes to improved durability, reducing the likelihood of failure under stress. Enhanced performance is another benefit, as the precise engineering of the sleeve ensures efficient power transmission, which can lead to better fuel efficiency and overall truck performance. For fleet operators, the use of this component may result in potential cost savings due to its longevity and reliability, reducing the need for frequent replacements or repairs.

Installation Considerations

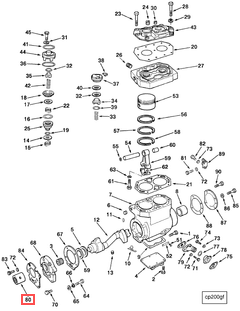

Proper installation of the 200824 Spline Coupling Sleeve is crucial for ensuring its effectiveness and the overall performance of the truck. Installation procedures should follow manufacturer guidelines, which may include specific prerequisites such as cleaning and inspecting the mating surfaces for damage or debris. The use of appropriate tools is recommended to ensure a secure fit without damaging the splines. Careful alignment during installation is also important to prevent undue stress on the component and to ensure optimal performance.

Maintenance and Troubleshooting

To ensure the longevity and optimal performance of the 200824 Spline Coupling Sleeve, regular maintenance is recommended. This may include periodic inspections for signs of wear or damage, as well as ensuring that all connections are secure and free from corrosion. Common issues that may arise include misalignment or excessive wear, which can be addressed through re-alignment or replacement as necessary. Following manufacturer-recommended maintenance schedules can help prevent these issues and ensure the component continues to function effectively.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company’s extensive product range is designed to meet the diverse needs of its customers, providing solutions that enhance the performance, efficiency, and reliability of heavy-duty vehicles.

Spline Coupling Sleeve (Part 200824) Compatibility with Cummins Engines

The Spline Coupling Sleeve, identified by the part number 200824, is a critical component in the operation of several Cummins engine models. This part is designed to ensure a secure and efficient connection between the engine and its associated components, facilitating smooth power transmission and operational integrity.

Compatible Engines

- ISM CM570, K19, L10 CELECT, L10 GAS, L10 MECHANICAL, M11 CELECT, M11 CELECT PLUS, M11 MECHANICAL, N14 CELECT, N14 CELECT PLUS, N14 MECHANICAL, QSM11 CM570, V28

The Spline Coupling Sleeve is engineered to fit seamlessly with the aforementioned Cummins engines. These engines span a range of applications, from industrial and marine to heavy-duty transportation, each requiring robust and reliable coupling solutions.

- L10 Series Engines

The L10 series, including variants such as CELECT, GAS, and MECHANICAL, benefit from the precise fit and durability of the Spline Coupling Sleeve. This ensures optimal performance and longevity in demanding environments.

- M11 Series Engines

Similarly, the M11 series, available in CELECT, CELECT PLUS, and MECHANICAL configurations, are designed to work with this coupling sleeve. The M11 engines are known for their power and efficiency, and the Spline Coupling Sleeve plays a crucial role in maintaining these characteristics.

- N14 Series Engines

The N14 series, with CELECT, CELECT PLUS, and MECHANICAL options, also integrates the Spline Coupling Sleeve. These engines are typically used in heavy-duty applications, where reliability and performance are paramount.

- ISM CM570, K19, QSM11 CM570, V28

The ISM CM570, K19, QSM11 CM570, and V28 engines also utilize the Spline Coupling Sleeve. Each of these engines is designed for specific applications, and the coupling sleeve ensures that they operate at peak efficiency.

Application Considerations

When installing the Spline Coupling Sleeve in any of the listed engines, it is essential to follow the manufacturer’s guidelines to ensure proper fit and function. This includes verifying the compatibility of the sleeve with the specific engine model and ensuring that all installation procedures are correctly followed to avoid any operational issues.

Role of Part 200824 Spline Coupling Sleeve in Engine Systems

The 200824 Spline Coupling Sleeve is an integral component in various engine systems, facilitating efficient power transmission and ensuring smooth operation of multiple accessories. Its application spans across several key components, enhancing their functionality and reliability.

Accessory Drive Systems

In accessory drive systems, the 200824 Spline Coupling Sleeve connects the engine’s crankshaft to the accessory drive, allowing for the transfer of rotational force. This connection is vital for operating components such as the alternator, power steering pump, and air conditioning compressor. The sleeve ensures that these accessories receive consistent power, maintaining their efficiency and longevity.

Accessory Drive Conversion Kits

When implementing an accessory drive conversion kit, the 200824 Spline Coupling Sleeve plays a significant role in adapting the engine to new accessory configurations. It provides a seamless interface between the engine and the converted accessory drive, ensuring that the new setup operates harmoniously with the existing engine components.

Air Compressor Drives

For air compressor drives, the 200824 Spline Coupling Sleeve is essential in transmitting power from the engine to the compressor. This connection is particularly important in systems where the compressor is used for various applications, such as pneumatic tools or vehicle air suspension. The sleeve’s design allows for efficient power transfer, reducing the risk of mechanical failure.

Compressor Mounting Systems

In compressor mounting systems, whether it’s a standard compressor mounting or a B-W air compressor mounting, the 200824 Spline Coupling Sleeve ensures a secure and efficient connection between the engine and the compressor. This is crucial for maintaining the compressor’s performance and preventing issues such as misalignment or excessive wear.

Twin Compressor Mounting

For systems utilizing twin compressor mounting, the 200824 Spline Coupling Sleeve facilitates the distribution of engine power to both compressors evenly. This balanced power transmission is essential for the synchronized operation of twin compressors, enhancing the overall efficiency of the system.

Conversion Kits and Accessory Kits

In the context of conversion kits and accessory kits, the 200824 Spline Coupling Sleeve acts as a universal connector, adapting to various engine and accessory configurations. Its versatility makes it a preferred choice for engineers and mechanics looking to upgrade or modify engine systems without compromising on performance.

EBM Compressor and Mounting Compressor

For EBM compressors and other mounting compressor setups, the 200824 Spline Coupling Sleeve ensures a robust and reliable connection. This is particularly beneficial in high-demand applications where the compressor is subjected to frequent use and varying loads.

Conclusion

The 200824 Spline Coupling Sleeve is a versatile and reliable component that enhances the performance and durability of various engine systems. Its role in facilitating efficient power transmission across different accessories and compressors makes it an indispensable part of modern engine design.

-

Lakshminarayanan, P. A., & Agarwal, A. K. (2019). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer.

↩ -

Berns, K., Dressler, K., Fleischmann, P., Grges, D., Kalmar, R., Sauer, B., Stephan, N., Teutsch, R., & Thul, M. (2018). Proceedings of the 5th Commercial Vehicle Technology Symposium CVT. Springer.

↩ -

Hilgers, M. (2023). Chassis and Axles. Springer Vieweg.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.