3955069

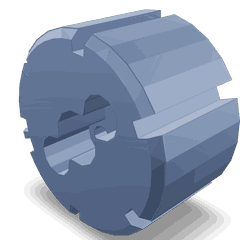

Speed Indicator Ring

Cummins®

IN STOCK

5 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3955069 Speed Indicator Ring is a critical component for commercial trucks, designed to enhance engine system functionality and performance. This part plays a role in monitoring and indicating the rotational speeds of specific engine components, providing essential data for the operation and maintenance of the vehicle 1.

Function and Operation

The Speed Indicator Ring interacts with sensors within the truck’s engine system. As engine components rotate, the ring passes by these sensors, generating signals that are processed to determine rotational speed. This interaction is vital for accurate engine performance monitoring, enabling real-time data collection on the speed of various engine parts 2.

Purpose of the Speed Indicator Ring

The primary function of the Speed Indicator Ring is to monitor and indicate the rotational speed of engine components. By providing precise speed data, it allows the engine control unit (ECU) to make adjustments for optimal performance. This monitoring ensures the engine operates within safe parameters, enhancing both performance and longevity 3.

Key Features

This Cummins part is characterized by high-durability materials designed to withstand harsh engine environments. Its precise engineering ensures accurate speed readings, and its compatibility with Cummins engines guarantees seamless integration into the system.

Benefits

The advantages of the Speed Indicator Ring include improved engine performance monitoring and more effective maintenance scheduling. By providing accurate speed data, it allows for better engine management, potentially leading to enhanced fuel efficiency and reduced wear on engine components. Additionally, the data collected can aid in predictive maintenance, helping to prevent unexpected breakdowns.

Installation Process

Installing the Speed Indicator Ring requires careful attention to detail. The process involves accessing the appropriate area within the engine, aligning the ring with the sensors, and securing it in place. Specific tools may be required to ensure a proper fit and function. It is important to follow manufacturer guidelines to avoid damage to the ring or surrounding components.

Common Issues and Troubleshooting

Typical problems associated with the Speed Indicator Ring may include inaccurate readings or sensor malfunctions. Troubleshooting often involves checking the alignment and condition of the ring, ensuring it is free from debris, and verifying the functionality of the sensors. Regular inspections can help identify issues before they lead to more significant problems.

Maintenance Tips

To ensure the longevity and reliability of the Speed Indicator Ring, regular maintenance is recommended. This includes periodic inspections for wear or damage, cleaning the ring and surrounding areas to prevent buildup, and verifying the integrity of the sensors. Adhering to these practices can help maintain the accuracy and functionality of the speed indication system.

Cummins Overview

Cummins Inc. is a well-established company in the commercial truck industry, known for its wide range of engine and power generation products. With a history of innovation and quality, Cummins has built a reputation for reliability and performance. The company’s product line includes engines, filtration systems, and aftermarket parts, all designed to meet the demanding requirements of commercial transportation.

Speed Indicator Ring Compatibility with Cummins Engines

The Speed Indicator Ring part number 3955069, manufactured by Cummins, is designed to fit a variety of Cummins engines. This part is crucial for accurately displaying the engine’s rotational speed, which is essential for monitoring performance and ensuring the engine operates within safe parameters.

B6.7 Series Engines

The Speed Indicator Ring is compatible with several B6.7 series engines, including:

- B6.7 CM2350 B135B

- B6.7 CM2670 B153B

- B6.7 CM2670 B164C

- B6.7 G CMOH6.0 B125

- QSB6.7 CM2250

- QSB6.7 CM2350 B105

- QSB6.7 CM850 (CM2850)

- QSB6.7 M CM2250

ISB Series Engines

The Speed Indicator Ring also fits various ISB series engines, such as:

- ISB CM2150

- ISB CM850

- ISB/ISD6.7 CM2150 SN

- ISB6.7 CM2250

- ISB6.7 CM2350 B101

- ISB6.7 G CM2180 B118

ISBE and ISF Series Engines

For ISBE and ISF series engines, the Speed Indicator Ring is compatible with:

- ISBE CM2150

- ISBE4 CM850

- ISF3.8 CM2220 AN

ISG Series Engines

The Speed Indicator Ring fits the following ISG series engines:

- ISG11 CM2880 G108

- ISG12 CM2880 G107

- ISG12 G CMOH6.0 G111

QSB and QSG Series Engines

The Speed Indicator Ring is also compatible with several QSB and QSG series engines, including:

- QSB7 CM2880 B117

- QSG12 CM2880 G112

- QSG12/X12 CM2350 G110

X11 and X12 Series Engines

Lastly, the Speed Indicator Ring fits the following X11 and X12 series engines:

- X11 CM2670 X126B

- X12 CM2350 X119B

This comprehensive compatibility ensures that the Speed Indicator Ring can be used across a wide range of Cummins engines, providing reliable and accurate speed readings for optimal engine performance.

Role of Part 3955069 Speed Indicator Ring in Engine Systems

The Speed Indicator Ring (part 3955069) is a vital component in the synchronization and monitoring of various engine systems. Its primary function is to provide accurate rotational speed data, which is essential for the precise operation of several engine components.

Integration with Key Engine Components

Camshaft

The Speed Indicator Ring works in conjunction with the camshaft to ensure that valve timing is accurately monitored. By providing real-time data on the rotational speed of the camshaft, it allows the engine control unit (ECU) to make necessary adjustments for optimal performance and efficiency.

Connecting Rod and Piston

In the connecting rod and piston assembly, the Speed Indicator Ring helps in monitoring the piston’s speed and position. This data is crucial for the ECU to manage fuel injection timing and ignition events, ensuring smooth and efficient engine operation.

Cylinder Head

The cylinder head benefits from the Speed Indicator Ring by receiving precise speed data that aids in the control of air and fuel mixture distribution. This enhances combustion efficiency and reduces emissions.

Cylinder Top Level Assembly Head

For the cylinder top level assembly head, the Speed Indicator Ring provides essential speed feedback that ensures the top-end components operate within their designed parameters, contributing to overall engine reliability and performance.

Injector

The injector system relies on the Speed Indicator Ring to synchronize fuel delivery with engine speed. This synchronization is key to maintaining the correct air-fuel ratio, which is critical for performance and emissions control.

Injector Plumbing

In the injector plumbing system, the Speed Indicator Ring ensures that fuel is delivered at the right moments, corresponding to engine speed. This precision helps in achieving better fuel economy and reduced wear on engine components.

Long Block

Within the long block assembly, the Speed Indicator Ring plays a role in monitoring the overall engine speed, providing data that is used to fine-tune various subsystems for peak performance.

Performance Parts

For performance parts, the Speed Indicator Ring is often utilized to gather data that can be used to push the engine beyond standard operating conditions. This data is invaluable for tuning and modifying engines to achieve higher performance levels while maintaining safety and reliability.

Conclusion

The Cummins 3955069 Speed Indicator Ring is an essential component for the accurate monitoring and synchronization of engine systems in commercial trucks. Its precise speed data collection enhances engine performance, ensures safe operation, and aids in predictive maintenance, ultimately contributing to the longevity and reliability of the vehicle.

-

Bonnick, A., & Newbold, D. (2011). A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition. Elsevier Ltd.

↩ -

Drozdziel, P. (2023). The Vehicle Diesel Engine Startup Process Operational and Environmental Aspects. Routledge.

↩ -

Limpert, R. (2011). Brake Design and Safety, Third Edition. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.