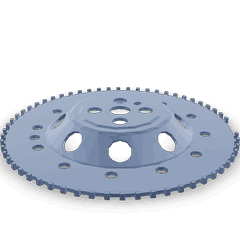

The Cummins 3974245 Speed Indicator Ring is a component designed for use in commercial trucks. Its purpose is to measure and indicate the rotational speed of the engine’s components, providing data for the vehicle’s operation. This part is significant in ensuring the truck operates efficiently and safely by offering accurate speed readings that contribute to the overall performance and maintenance of the vehicle 2.

Basic Concepts and Functionality

The Speed Indicator Ring operates on the principle of generating a signal based on the rotational speed of the engine’s components. It interacts with sensors within the truck’s systems to produce an electrical signal that corresponds to the speed of rotation. This signal is then processed by the vehicle’s electronic control unit (ECU) to display the speed on the dashboard and to make adjustments to the engine’s operation as necessary 1.

Purpose and Role

This Cummins part plays a specific role in the operation of a truck by measuring and indicating the speed of engine components. It ensures that the driver has accurate information about the engine’s performance, which is vital for safe and efficient driving. Additionally, the data provided by the Speed Indicator Ring is used by the truck’s systems to optimize fuel efficiency, manage engine load, and facilitate timely maintenance 2.

Key Features

The primary features of the 3974245 include its robust design, which is engineered to withstand the harsh conditions of commercial truck operation. It is constructed from durable materials that ensure longevity and reliability. Unique characteristics such as its precise machining and compatibility with various sensor types enhance its performance and integration within the truck’s systems 2.

Benefits

The advantages provided by the Speed Indicator Ring include improved accuracy in speed measurement, which leads to better engine management and fuel efficiency. Its enhanced durability ensures long-term reliability, reducing the need for frequent replacements. Additionally, the precise data it provides can contribute to overall truck performance by enabling more accurate diagnostics and maintenance scheduling 2.

Installation and Integration

Proper installation of the Speed Indicator Ring within the truck’s systems requires careful attention to ensure it is correctly aligned and securely fastened. Preparations may include cleaning the installation area and verifying that all connections are compatible with the truck’s existing systems. It is important to follow manufacturer guidelines to ensure the ring is integrated effectively without causing disruptions to other components 2.

Troubleshooting and Maintenance

Identifying and addressing common issues related to the Speed Indicator Ring may involve checking for proper alignment, ensuring connections are secure, and verifying that the ring is free from debris or damage. Routine maintenance practices include regular inspection for wear and tear, cleaning the component to remove any buildup, and calibrating the system to maintain accuracy in speed readings 2.

Cummins Overview

Cummins Inc. is a well-established company with a strong reputation in the automotive industry for producing high-quality components. With a history of innovation and commitment to excellence, Cummins has become a trusted name among commercial truck manufacturers and operators. The company’s dedication to quality is evident in the design and manufacturing of components like the 3974245, which are built to meet the demanding requirements of commercial vehicle applications 2.

Cummins Speed Indicator Ring 3974245 Compatibility

The Cummins Speed Indicator Ring part number 3974245 is designed to be compatible with a range of Cummins engines, including the ISB CM850 and QSB5.9 CM850. This part is essential for accurately measuring and displaying the engine’s rotational speed, which is crucial for monitoring performance and ensuring optimal operation 2.

ISB CM850

The ISB CM850 engine is a robust and reliable power unit, widely used in various applications. The Speed Indicator Ring 3974245 fits seamlessly into this engine, providing precise speed readings that are vital for both performance and maintenance purposes. This compatibility ensures that operators can rely on accurate data for making informed decisions about engine operation and maintenance 2.

QSB5.9 CM850

Similarly, the QSB5.9 CM850 engine benefits from the use of the Speed Indicator Ring 3974245. This part is engineered to integrate smoothly with the QSB5.9 CM850, ensuring that the engine’s speed is accurately measured and displayed. This is particularly important for applications where precise speed control is necessary for optimal performance and efficiency 2.

Grouping for Compatibility

Both the ISB CM850 and QSB5.9 CM850 engines fall under the category of Cummins’ high-performance diesel engines, designed for demanding applications. The Speed Indicator Ring 3974245 is specifically designed to fit these engines, ensuring that they operate at peak efficiency and reliability. This compatibility highlights the versatility and precision of Cummins components, making them a reliable choice for a wide range of applications 2.

Role of Part 3974245 Speed Indicator Ring in Engine Systems

The Speed Indicator Ring is an integral component in the operation of various engine systems, particularly in ensuring accurate measurement and monitoring of rotational speed. This component interfaces with several key elements within the engine, enhancing overall performance and reliability 2.

Interaction with the Damper

In engine systems equipped with a damper, the Speed Indicator Ring plays a significant role. The damper is designed to absorb vibrations and reduce oscillations within the engine. As the engine operates, the Speed Indicator Ring provides real-time data on the rotational speed of the damper. This information allows for precise adjustments to be made, ensuring that the damper effectively mitigates vibrations. The continuous feedback loop created by the Speed Indicator Ring helps maintain optimal damper performance, leading to smoother engine operation and reduced wear on connected components 2.

Contribution to Vibration Management

Vibration management is another area where the Speed Indicator Ring proves invaluable. Engines inherently produce vibrations during operation, which, if left unchecked, can lead to increased stress on various components and decreased efficiency. The Speed Indicator Ring monitors the rotational speed of parts susceptible to vibration, such as the crankshaft or turbine blades. By providing accurate speed data, it enables the engine control unit (ECU) to implement necessary corrections. These corrections may include adjusting fuel injection timing, altering ignition timing, or modifying the operation of active vibration control systems. The result is a more stable engine performance with minimized vibrational impacts 2.

Enhanced System Integration

The integration of the Speed Indicator Ring with other engine components, such as sensors and the ECU, further enhances its functionality. The ring’s precise speed measurements are vital for the ECU to make informed decisions regarding engine operation. Whether it’s optimizing fuel efficiency, ensuring smooth power delivery, or protecting the engine from overspeed conditions, the data from the Speed Indicator Ring is fundamental. This seamless integration ensures that the engine operates within safe parameters while delivering peak performance 2.

Conclusion

In summary, the Speed Indicator Ring is a key component in modern engine systems, providing essential data that contributes to the effective management of dampers and vibrations. Its role in enhancing engine performance and reliability underscores the importance of accurate speed measurement in complex mechanical systems 2.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.