This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3092002 Mounting Spacer is a component designed for use in heavy-duty truck applications. Its purpose is to provide the necessary spacing and alignment between various truck components during assembly and operation. This part plays a role in ensuring that components are correctly positioned, which is important for the efficient and reliable performance of the truck’s systems 1.

Purpose and Function

The mounting spacer serves a specific function within the assembly of truck components. It facilitates proper alignment and spacing, which are important for the optimal operation of mechanical systems. By maintaining the correct distance between parts, the spacer helps to ensure that components fit together seamlessly, reducing the risk of misalignment that could lead to increased wear or failure 2.

Key Features

The Cummins 3092002 Mounting Spacer is characterized by its design and material properties. It is crafted from durable materials that can withstand the rigors of heavy-duty truck environments. The spacer’s design is tailored to fit precisely within the truck’s component assembly, ensuring a snug and secure fit. Its unique attributes contribute to enhanced performance and longevity, making it a reliable choice for truck maintenance and repair 3.

Benefits

Utilizing the Cummins 3092002 Mounting Spacer offers several advantages. It contributes to improved component alignment, which can lead to reduced wear on moving parts and a decrease in the likelihood of mechanical failures. Additionally, the spacer can enhance the overall efficiency of the truck’s systems by ensuring that components operate within their designed parameters. This can result in better performance and potentially lower maintenance costs over time 4.

Installation Considerations

Correct installation of the mounting spacer is important for its performance and longevity. It is recommended to follow specific procedures to ensure that the spacer is properly positioned and secured. This includes using the appropriate torque settings for fasteners and performing alignment checks to confirm that the spacer is correctly installed. Attention to these details during installation can help to prevent issues down the line 5.

Maintenance and Troubleshooting

Routine inspection and maintenance of the mounting spacer are recommended to ensure its continued proper function. This may involve checking for signs of wear or damage and ensuring that it remains securely in place. Common issues that may arise with mounting spacers include loosening over time or damage from exposure to the elements. Troubleshooting steps may include re-torquing fasteners or replacing the spacer if it is found to be compromised 6.

Compatibility and Applications

The Cummins 3092002 Mounting Spacer is designed for use in specific truck models and systems. It is compatible with a range of components within these applications, serving as a vital link in the assembly process. Its design allows it to integrate seamlessly with other parts, contributing to the overall functionality of the truck’s mechanical systems 7.

Manufacturer Overview - Cummins

Cummins Inc. is a well-established company with a history of expertise in diesel engine manufacturing. The company is known for its commitment to quality and innovation within the automotive industry. Cummins’ products, including the 3092002 Mounting Spacer, are designed with a focus on reliability and performance, reflecting the company’s dedication to meeting the needs of its customers in the heavy-duty truck sector 8.

Role of Part 3092002 Mounting Spacer in Engine Systems

The 3092002 Mounting Spacer is integral to the assembly and functionality of various engine components. It ensures proper alignment and spacing between components, which is important for the efficient operation of the engine system 9.

Harness and Electronic Control Module (ECM) Wiring

In the context of the harness and ECM wiring, the 3092002 Mounting Spacer facilitates the secure attachment of the wiring harness to the engine block or other structural components. This ensures that the wiring remains organized and protected from potential damage due to vibrations or contact with other parts. Proper spacing provided by the mounting spacer also helps in maintaining the integrity of the electrical connections, which is vital for the reliable transmission of signals between the ECM and various engine sensors and actuators 10.

Plumbing and Fuel Systems

For the plumbing and fuel systems, the 3092002 Mounting Spacer plays a role in the accurate placement of fuel lines and plumbing components. It ensures that these components are held in the correct position, which is important for maintaining the proper flow of fuel and other fluids. This alignment helps prevent leaks and ensures that the fuel delivery system operates efficiently, contributing to the overall performance and reliability of the engine 11.

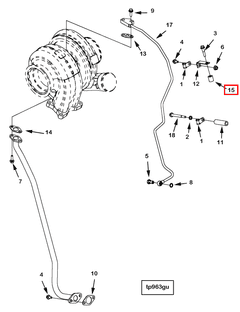

Turbocharger and Turbocharger Kit

In turbocharger and turbocharger kit installations, the 3092002 Mounting Spacer is used to maintain the correct distance between the turbocharger and the engine block or other mounting points. This is important for the efficient operation of the turbocharger, as it ensures that the turbine and compressor sections are aligned properly. The spacer also helps in managing the thermal expansion that occurs during engine operation, reducing the risk of component failure due to excessive heat or mechanical stress 12.

Conclusion

The Cummins 3092002 Mounting Spacer is a critical component in the assembly and operation of heavy-duty truck engines. Its role in ensuring proper alignment and spacing between components contributes to the efficient and reliable performance of the truck’s systems. Proper installation, maintenance, and understanding of its applications are key to leveraging the benefits of this Cummins part.

-

Denton, T., & Pells, H. (2022). Automotive Technician Training Theory. Routledge.

↩ -

Boger, T., & Cutler, W. (2018). Reducing Particulate Emissions in Gasoline Engines. SAE International.

↩ -

Berns, K., Dressler, K., Fleischmann, P., Grges, D., Kalmar, R., Sauer, B., Stephan, N., Teutsch, R., & Thul, M. (2018). Proceedings of the 5th Commercial Vehicle Technology Symposium CVT. Springer.

↩ -

Cummins Inc. (n.d.). Service Manual (5579947). Cummins Inc.

↩ -

Denton, T., & Pells, H. (2022). Automotive Technician Training Theory. Routledge.

↩ -

Boger, T., & Cutler, W. (2018). Reducing Particulate Emissions in Gasoline Engines. SAE International.

↩ -

Berns, K., Dressler, K., Fleischmann, P., Grges, D., Kalmar, R., Sauer, B., Stephan, N., Teutsch, R., & Thul, M. (2018). Proceedings of the 5th Commercial Vehicle Technology Symposium CVT. Springer.

↩ -

Cummins Inc. (n.d.). Service Manual (5579947). Cummins Inc.

↩ -

Denton, T., & Pells, H. (2022). Automotive Technician Training Theory. Routledge.

↩ -

Boger, T., & Cutler, W. (2018). Reducing Particulate Emissions in Gasoline Engines. SAE International.

↩ -

Berns, K., Dressler, K., Fleischmann, P., Grges, D., Kalmar, R., Sauer, B., Stephan, N., Teutsch, R., & Thul, M. (2018). Proceedings of the 5th Commercial Vehicle Technology Symposium CVT. Springer.

↩ -

Cummins Inc. (n.d.). Service Manual (5579947). Cummins Inc.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.