This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3008019 Spacer, manufactured by Cummins, is a critical component in the commercial truck industry. This part ensures the proper functioning of various mechanical systems by maintaining the necessary spacing and alignment between components. Spacers are fundamental to mechanical assemblies, contributing to system stability and performance 1.

Basic Concepts of Spacers

Spacers are mechanical components designed to create and maintain a specific distance between parts within an assembly. They are essential for the stability and performance of mechanical systems, ensuring components are correctly aligned and spaced. Proper spacing is vital for the efficient operation of machinery, as incorrect spacing can lead to increased wear, reduced performance, and potential system failure 2.

Purpose of the 3008019 Spacer

The 3008019 Spacer is designed to maintain proper spacing and alignment in commercial truck assemblies. By ensuring components are correctly positioned, this Cummins part facilitates the smooth operation of the truck’s mechanical systems. It prevents undue stress on components that can arise from misalignment or incorrect spacing 3.

Key Features

This Cummins part is characterized by its precise design and high-quality materials. It is manufactured to exact dimensions for a perfect fit within truck assemblies. The spacer is made from durable materials that can withstand the rigors of commercial truck operation, ensuring longevity and reliability. Unique design elements may include anti-rotation tabs or specific surface treatments to improve compatibility with other components 4.

Benefits of Using the 3008019 Spacer

Incorporating the 3008019 Spacer into truck assemblies offers several advantages. It contributes to improved performance by ensuring components operate within their designed parameters. The spacer enhances the durability of the mechanical system by preventing excessive wear on parts due to misalignment. Additionally, it increases the reliability of the system, reducing the likelihood of unexpected failures 5.

Installation Considerations

Correct installation of the 3008019 Spacer is crucial for its effective function. Guidelines for installation include ensuring proper torque settings are applied and that the spacer is correctly aligned with other components. Attention to these details during installation helps to maximize the spacer’s effectiveness and the overall performance of the truck’s mechanical system 6.

Troubleshooting Common Issues

Common problems associated with spacers can include wear and tear or misalignment. Diagnosing these issues involves inspecting the spacer for signs of damage or improper positioning. Resolving these issues may require replacing the spacer or adjusting the alignment of components to ensure correct spacing 7.

Maintenance Tips

Regular maintenance of the 3008019 Spacer is important for ensuring its longevity and optimal performance. This includes periodic inspections to check for signs of wear or damage. If necessary, the spacer should be replaced to maintain the efficiency and reliability of the truck’s mechanical systems 8.

Cummins: Manufacturer Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its commitment to quality and innovation. With a broad product range that includes engines, filtration systems, and aftermarket parts, Cummins has established a reputation for producing reliable and high-performance components. The company’s dedication to excellence is reflected in its products, including the 3008019 Spacer, which is designed to meet the demanding requirements of commercial truck applications 9.

Role of Part 3008019 Spacer in Engine Systems

The 3008019 Spacer is an essential component in maintaining the proper functioning and alignment of various engine systems. Its application spans across multiple components, ensuring optimal performance and longevity.

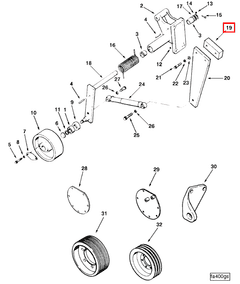

Fan Drive Mounting

In the fan drive mounting system, the 3008019 Spacer is utilized to maintain the correct distance between the fan drive and the engine block. This spacing is vital for the efficient operation of the fan, which is responsible for cooling the engine by drawing air through the radiator. Proper spacing ensures that the fan operates within its designed parameters, preventing overheating and potential engine damage 10.

Idler Arm

Within the steering system, the 3008019 Spacer plays a significant role in the idler arm assembly. The idler arm is a pivotal component that connects the pitman arm to the steering linkage, allowing for smooth and precise steering. The spacer ensures that the idler arm is correctly positioned relative to other steering components, which is essential for maintaining alignment and reducing wear on the steering system. This, in turn, contributes to a more responsive and safer driving experience 11.

Shock Absorber

In the suspension system, the 3008019 Spacer is often employed in the shock absorber assembly. Shock absorbers are designed to dampen the motion of the vehicle’s springs, providing a smoother ride and better handling. The spacer helps in maintaining the correct alignment and spacing between the shock absorber and other suspension components. This ensures that the shock absorber functions effectively, absorbing impacts from the road and minimizing the transfer of vibrations to the vehicle’s chassis 12.

Conclusion

Overall, the 3008019 Spacer is a versatile component that enhances the performance and reliability of various engine and vehicle systems by ensuring proper alignment and spacing. Its precise design and high-quality materials make it a critical part in the maintenance and operation of commercial trucks.

-

Bell, Joseph A. Modern Diesel Technology Electricity Electronics. Delmar Cengage Learning, 2014.

↩ -

Mom, Gijs. The Evolution of Automotive Engineering: A Handbook. SAE International, 2023.

↩ -

Martyr, A.J. Engine Testing: Theory and Practice: Third Edition. SAE International, 2007.

↩ -

Cummins Inc. QSK60 CM2350 K117, Service Manual (4367449).

↩ -

Bell, Joseph A. Modern Diesel Technology Electricity Electronics. Delmar Cengage Learning, 2014.

↩ -

Martyr, A.J. Engine Testing: Theory and Practice: Third Edition. SAE International, 2007.

↩ -

Cummins Inc. QSK60 CM2350 K117, Service Manual (4367449).

↩ -

Mom, Gijs. The Evolution of Automotive Engineering: A Handbook. SAE International, 2023.

↩ -

Cummins Inc. QSK60 CM2350 K117, Service Manual (4367449).

↩ -

Bell, Joseph A. Modern Diesel Technology Electricity Electronics. Delmar Cengage Learning, 2014.

↩ -

Martyr, A.J. Engine Testing: Theory and Practice: Third Edition. SAE International, 2007.

↩ -

Cummins Inc. QSK60 CM2350 K117, Service Manual (4367449).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.