This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

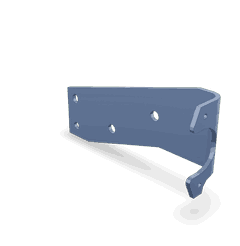

The 3923256 Solenoid Bracket, manufactured by Cummins, is a component designed for use in commercial truck operations. Cummins, a well-established name in the industry, produces a range of parts and systems that contribute to the efficiency and reliability of heavy-duty trucks. This Cummins part is part of this lineup, playing a specific role in the electrical systems of trucks.

Basic Concepts of Solenoid Brackets

A solenoid bracket serves as a mounting point for solenoids within a truck’s electrical system. Solenoids are electromechanical devices that convert electrical energy into mechanical motion, often used to control various functions in a truck, such as gear shifting or valve operations. The bracket not only secures the solenoid in place but also facilitates its interaction with other electrical components, ensuring smooth and reliable operation 1.

Purpose of the 3923256 Solenoid Bracket

This part is designed to support and secure solenoids in commercial trucks. It plays a role in managing electrical connections, ensuring that solenoids operate correctly and contribute to the overall performance of the truck. By providing a stable mounting solution, it helps maintain the integrity of the electrical system, allowing for reliable operation of solenoid-operated systems.

Key Features

The 3923256 is constructed from durable materials, designed to withstand the rigors of commercial truck environments. Its design includes features that enhance durability, such as corrosion-resistant coatings and robust mounting points. These attributes contribute to its longevity and reliability in demanding applications 2.

Benefits

The use of the 3923256 offers several advantages. Its robust design contributes to improved reliability of the electrical system. The bracket is also designed for ease of installation, reducing downtime during maintenance procedures. Over time, its durable construction can lead to potential cost savings by minimizing the need for frequent replacements.

Installation Process

Installing this part involves several steps to ensure a secure and effective fit. Preparatory steps include cleaning the mounting area and ensuring all electrical connections are secure. The necessary tools for installation may include wrenches and screwdrivers. Following the manufacturer’s guidelines for installation is recommended to achieve the best results.

Troubleshooting Common Issues

Common issues with solenoid brackets may include electrical faults or physical damage. Troubleshooting steps can involve checking electrical connections for corrosion or looseness, inspecting the bracket for signs of wear or damage, and ensuring that the solenoid is correctly mounted and operational. Addressing these issues promptly can help maintain the efficiency of the truck’s electrical system 3.

Maintenance Tips

Regular maintenance of the 3923256 can prolong its life and ensure reliable operation. This includes routine inspections for signs of wear or damage, cleaning the bracket and surrounding areas to prevent corrosion, and checking electrical connections for tightness and integrity. Knowing when to consider replacement is also part of effective maintenance, ensuring the bracket continues to perform its function reliably.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and focus on reliability make it a preferred choice for commercial truck operators and manufacturers.

Role of Part 3923256 Solenoid Bracket in Engine Systems

The 3923256 is an essential component in the orchestration of engine operations, particularly in systems involving the valve and fuel shutoff mechanisms.

In systems equipped with solenoid-operated valves, the solenoid bracket provides a stable mounting point for the solenoid, ensuring it is correctly positioned to interact with the valve. This interaction is fundamental for the precise control of fluid or gas flow within the engine. The bracket’s design allows for efficient transmission of the solenoid’s actuating force to the valve, enabling quick and reliable operation. This is particularly important in high-performance engines where timing and precision are paramount 4.

For fuel shutoff systems, the solenoid bracket plays a similarly important role. It secures the solenoid in a position that allows it to engage with the shutoff mechanism effectively. When the engine control unit (ECU) signals for a shutdown, the solenoid activates, and the bracket ensures that the force is adequately transmitted to the shutoff valve, enabling a swift and complete cessation of fuel flow. This is vital for safety, especially in emergency situations where immediate engine shutdown is required.

Overall, the 3923256 is integral to the reliable and efficient operation of solenoid-driven components within engine systems, contributing to both performance and safety.

Conclusion

The 3923256 Solenoid Bracket by Cummins is a critical component in the electrical systems of commercial trucks, ensuring the reliable operation of solenoid-driven functions. Its durable construction, ease of installation, and role in maintaining system integrity make it a valuable part for truck operators and manufacturers alike.

-

Huzij, R., Spano, A., & Bennett, S. (2019). Modern Diesel Technology: Heavy Equipment Systems. Cengage Learning.

↩ -

Hick, H., Kupper, K., & Sorger, H. (2021). Systems Engineering for Automotive Powertrain Development. Springer.

↩ -

Giles, T. (2019). Automotive Engines Diagnosis Repair and Rebuilding. Cengage Learning.

↩ -

Lakshminarayanan, P. A., & Aghav, Y. V. (2010). Modelling Diesel Combustion. Springer Science.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.