This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

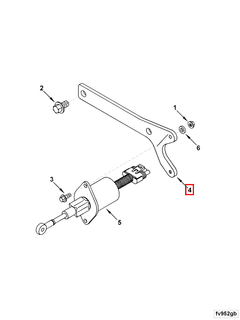

The Cummins 3934146 Solenoid Bracket is a component designed for use in commercial trucks. It serves a specific function within the truck’s operational system, contributing to the overall efficiency and reliability of the vehicle. Understanding its purpose and role is fundamental for maintaining and optimizing the performance of commercial trucks.

Basic Concepts of Solenoid Brackets

A solenoid bracket is a mounting component used to secure a solenoid, which is an electromechanical device that converts electrical energy into mechanical motion. In automotive systems, solenoids are commonly used to control various functions such as fuel injection, gear shifting, and valve operation. The solenoid bracket ensures that the solenoid is properly positioned and supported, allowing it to function effectively within the system 1.

Purpose of the Cummins 3934146 Solenoid Bracket

This Cummins part is specifically designed to mount the solenoid in commercial trucks equipped with Cummins engines. It plays a role in the truck’s operation by securely holding the solenoid in place, ensuring it can interact correctly with other components such as the engine control unit (ECU) and various sensors. This interaction is vital for the precise control of engine functions, contributing to the truck’s overall performance and efficiency.

Key Features

The Cummins 3934146 Solenoid Bracket is constructed from durable materials to withstand the rigors of commercial truck operation. Its design includes features such as precise mounting points and robust construction to ensure a secure fit. Additionally, the bracket may incorporate elements that facilitate easy installation and maintenance, enhancing its functionality in a commercial setting.

Benefits

The use of the Cummins 3934146 Solenoid Bracket offers several advantages. It contributes to improved reliability by ensuring the solenoid is securely mounted and correctly aligned. This can lead to enhanced engine performance and efficiency, as the solenoid’s function is critical for various engine control processes. Furthermore, the bracket’s design may include features that simplify maintenance, reducing downtime and operational costs 2.

Installation Process

Installing the Cummins 3934146 Solenoid Bracket requires careful attention to ensure proper alignment and secure mounting. The process involves identifying the correct location on the truck’s engine compartment, aligning the bracket with the mounting points, and securing it in place using the appropriate fasteners. It is important to follow the manufacturer’s instructions to ensure the bracket is installed correctly and functions as intended.

Common Issues and Troubleshooting

Frequent problems associated with solenoid brackets can include loose mounting, which may affect the solenoid’s operation, and corrosion, which can impair the bracket’s structural integrity. Troubleshooting these issues involves inspecting the bracket for signs of wear or damage, ensuring it is securely fastened, and addressing any corrosion with appropriate treatments. Regular checks can help identify and resolve these issues before they lead to more significant problems.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 3934146 Solenoid Bracket, routine maintenance practices are recommended. This includes regular inspections for signs of wear, corrosion, or loose mounting. Cleaning the bracket and its surrounding area can prevent the buildup of dirt and debris, which may interfere with its function. Additionally, ensuring that all fasteners are tight and in good condition will help maintain the bracket’s secure fit.

Compatibility and Applications

The Cummins 3934146 Solenoid Bracket is designed for use with specific types of trucks and engine models. Its compatibility ensures that it can be effectively integrated into the truck’s system, contributing to the vehicle’s performance and reliability. Understanding the bracket’s applications and compatibility is important for selecting the correct component for a given truck and engine configuration.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history of innovation and a strong reputation in the commercial truck industry, Cummins products are known for their reliability, performance, and efficiency. The company’s commitment to quality and customer satisfaction has established it as a trusted name in the automotive and heavy-duty truck sectors.

Cummins Solenoid Bracket 3934146 Compatibility

The Cummins Solenoid Bracket part number 3934146 is designed to be compatible with several engine models, ensuring a secure and reliable mounting solution for solenoids. This bracket is integral in maintaining the proper alignment and functionality of the solenoids, which are critical for engine operation.

Compatible Engines

- 4B3.9

- 5.9L Cummins

- 6.7L Cummins

These engines benefit from the precise engineering of the 3934146 Solenoid Bracket, which is crafted to fit seamlessly within the engine’s architecture. The bracket’s design allows for easy installation and ensures that the solenoids are held firmly in place, reducing the risk of movement or misalignment during operation.

The compatibility of this bracket with the listed engines underscores its versatility and reliability in various engine configurations. Cummins has ensured that this part meets the stringent requirements for performance and durability, making it a trusted choice for maintaining engine integrity.

Role of Part 3934146 Solenoid Bracket in Engine Systems

The Solenoid Bracket, identified by part number 3934146, is an essential component in the orchestration of various engine systems, particularly in relation to the valve and fuel shutoff mechanisms.

Integration with the Valve System

In engine systems, the valve plays a pivotal role in controlling the flow of gases into and out of the combustion chamber. The Solenoid Bracket securely mounts the solenoid, which in turn operates the valve. This bracket ensures that the solenoid is positioned accurately and remains stable under the dynamic conditions within the engine. The precise placement facilitated by the bracket allows for optimal valve operation, which is fundamental for maintaining the engine’s efficiency and performance.

Function in the Fuel Shutoff System

The fuel shutoff system is designed to halt the fuel supply to the engine under specific conditions, such as during emergencies or when the engine is turned off. The Solenoid Bracket is integral to this system as it supports the solenoid that controls the shutoff valve. By providing a stable mounting point, the bracket ensures that the solenoid can effectively and reliably engage or disengage the shutoff valve. This reliability is key to preventing fuel leakage and ensuring safety.

Synergy Between Components

The interplay between the Solenoid Bracket, valve, and fuel shutoff system underscores the importance of each component working in harmony. The bracket’s role in securing the solenoid is not just about physical attachment; it’s about enabling the solenoid to perform its function with precision and consistency. This, in turn, allows the valve and fuel shutoff system to operate as intended, contributing to the overall reliability and safety of the engine system.

Conclusion

The Cummins 3934146 Solenoid Bracket is a critical component in the operation of commercial trucks, particularly those equipped with Cummins engines. Its role in securely mounting the solenoid ensures the precise control of engine functions, contributing to the vehicle’s performance and efficiency. Understanding the bracket’s purpose, features, and benefits is essential for maintaining and optimizing the performance of commercial trucks. Regular maintenance and proper installation are key to ensuring the longevity and reliability of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.