This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

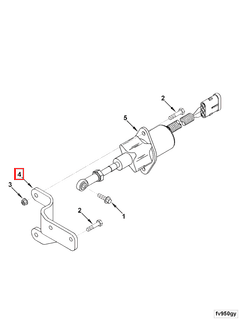

The Cummins Solenoid Bracket, part number 3933713, is a critical component in commercial truck engine systems. It supports the operation of solenoids, which are electrically controlled switches that regulate various engine functions. Understanding the role of this part is essential for maintaining and optimizing the performance of truck engine systems.

Basic Concepts of Solenoid Brackets

A solenoid bracket serves as a mounting point for solenoids within an engine system, ensuring they are securely positioned and properly aligned with other engine components. The operation of a solenoid involves both mechanical and electrical aspects: when an electrical current is applied, the solenoid’s coil generates a magnetic field that moves a plunger, which in turn operates a valve or switch within the engine system. The solenoid bracket facilitates this process by providing a stable base for the solenoid and ensuring its correct orientation and operation 1.

Purpose of the Cummins Solenoid Bracket

The Cummins Solenoid Bracket, part number 3933713, is designed to support the efficient and reliable operation of truck engines. It securely holds the solenoid in place, allowing it to interact correctly with other components. This bracket supports both electrical and mechanical processes within the engine, ensuring that the solenoid can effectively regulate engine functions such as fuel injection timing and valve operation. Its role is integral to maintaining the overall performance and reliability of the engine system 2.

Key Features

This Cummins part is characterized by its robust design and the use of high-quality materials, which enhance its performance and durability. Its design ensures a secure fit for the solenoid, minimizing the risk of misalignment or detachment. The materials used in its construction are chosen for their strength and resistance to corrosion, contributing to the bracket’s longevity and reliability in the demanding environment of a commercial truck engine.

Benefits

Using the Cummins Solenoid Bracket can lead to improved engine performance and reliability. Its design and construction contribute to the efficient operation of the solenoid, which in turn supports optimal engine function. For truck operators and fleet managers, this translates into benefits such as reduced maintenance needs, enhanced engine efficiency, and increased uptime, all of which contribute to operational cost savings and improved productivity.

Installation and Compatibility

Proper installation of the Cummins Solenoid Bracket is important for ensuring its effectiveness and the overall performance of the engine system. Installation guidelines should be followed to ensure that the bracket is correctly positioned and securely fastened. Compatibility with various truck models and engine types is a consideration to ensure that the bracket is suitable for the specific application.

Troubleshooting and Maintenance

Common issues with solenoid brackets can include misalignment, corrosion, or damage from vibrations. Regular maintenance, such as inspection for signs of wear or corrosion and ensuring secure fastening, can help prevent these issues. Diagnostic procedures for identifying problems related to the solenoid bracket may involve checking for proper alignment and secure attachment, as well as testing the electrical connections to the solenoid.

Safety Considerations

When handling, installing, or maintaining the Cummins Solenoid Bracket, it is important to follow safety guidelines to mitigate potential risks. These include ensuring that the engine is turned off and cooled down before beginning work, using appropriate personal protective equipment, and following manufacturer guidelines for installation and maintenance. Improper installation or maintenance can lead to engine malfunctions or safety hazards, underscoring the importance of adhering to safety protocols.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins serves commercial truck, bus, construction, agricultural, and power generation markets. Its product range includes a variety of engine components and systems designed to meet the demanding requirements of these industries, demonstrating Cummins’ dedication to advancing technology and improving efficiency in power solutions 3.

Cummins Solenoid Bracket 3933713 Compatibility

The Cummins Solenoid Bracket part number 3933713 is designed to fit seamlessly with a variety of Cummins engines, ensuring a secure and reliable mounting for solenoids. This bracket is essential for maintaining the proper alignment and function of solenoids within the engine system.

Compatible Engines

- 4B3.9

- 5.9L Cummins

- 6.7L Cummins

Engine Grouping

The Cummins Solenoid Bracket 3933713 is particularly well-suited for the following engine groups:

- 4B Series: This includes the 4B3.9 engine, which is known for its robust performance and reliability in various applications.

- 5.9L Cummins Engines: These engines are widely used in heavy-duty trucks and industrial applications, providing a balance of power and efficiency.

- 6.7L Cummins Engines: These engines are part of the newer generation of Cummins powerplants, offering enhanced performance and fuel efficiency.

The bracket’s design ensures it fits snugly and securely with these engines, providing a stable platform for solenoids and contributing to the overall reliability and longevity of the engine system.

Conclusion

The Cummins Solenoid Bracket, part number 3933713, plays a vital role in the operation and maintenance of commercial truck engines. Its robust design, compatibility with various Cummins engines, and the benefits it offers in terms of engine performance and reliability make it an essential component for truck operators and fleet managers. Proper installation, regular maintenance, and adherence to safety guidelines are crucial for maximizing the effectiveness of this part and ensuring the longevity and efficiency of the engine system.

-

Kasab, John, and Andrea Strzelec. Automotive Emissions Regulations and Exhaust Aftertreatment Systems. SAE International, 2020.

↩ -

Randall, Martynn. Haynes Manual on Diesel Engines. Haynes Publishing, 2015.

↩ -

Boyce, Meherwan P. Gas Turbine Engineering Handbook 4th Edition. Butterworth-Heinemann, 2011.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.