This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3903577 Solenoid O-Ring is a critical component in commercial trucks, designed to enhance the efficiency and reliability of the vehicle’s solenoid valve system. This part ensures the proper operation of the truck’s systems by maintaining the integrity of the solenoid valve.

Basic Concepts of Solenoid O-Rings

A solenoid O-ring is a circular rubber seal that fits around the solenoid valve’s plunger or armature, creating a seal that prevents fluid or gas leakage within the system 1. Its elasticity allows it to conform to the surfaces it seals against, maintaining pressure and ensuring the solenoid valve operates correctly.

Purpose and Function in Truck Operation

This Cummins part plays a role in the operation of a truck by ensuring the solenoid valve functions correctly within the fuel system and emission control systems. It helps maintain the seal around the solenoid’s moving parts, which is vital for controlling the flow of fuel or emissions-related fluids. This, in turn, contributes to the truck’s overall performance, fuel efficiency, and compliance with emission standards.

Key Features

The 3903577 is characterized by its material composition, typically made from durable elastomers designed to withstand the harsh conditions within a truck’s engine compartment. Its design specifications are tailored to fit precisely within the solenoid valve, enhancing its performance and longevity. The O-ring’s durability ensures it can endure repeated cycles of compression and release without failing, which is crucial for the reliable operation of the solenoid valve.

Benefits of Using Cummins Solenoid O-Rings

Utilizing Cummins-manufactured solenoid O-rings offers several advantages. These O-rings are engineered to meet Cummins’ stringent quality standards, ensuring reliability and compatibility with Cummins systems. They contribute to overall engine efficiency by maintaining the integrity of the solenoid valve, which is vital for the precise control of fuel and emissions systems.

Installation and Replacement Guidelines

Proper installation and replacement of the Solenoid O-Ring require attention to detail and the use of appropriate tools. The process involves carefully removing the old O-ring, inspecting the solenoid valve for any damage, and installing the new O-ring with the correct orientation. Safety precautions, such as wearing gloves and ensuring the work area is clean, are important to prevent contamination and ensure a secure fit.

Troubleshooting Common Issues

Common problems associated with solenoid O-rings include leaks or failure to seal properly. These issues can often be traced back to wear and tear, improper installation, or compatibility issues. Troubleshooting methods may involve inspecting the O-ring for signs of damage, ensuring it is correctly installed, and verifying its compatibility with the solenoid valve.

Maintenance Tips

To ensure the longevity and optimal performance of the 3903577, regular inspections are recommended. Signs of wear, such as cracks or deformation, should be addressed promptly to prevent leaks and ensure the solenoid valve continues to operate efficiently. Adhering to manufacturer-recommended inspection intervals can help identify potential issues before they lead to more significant problems.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is committed to quality and innovation in the diesel engine and related technologies market. The company’s product range includes engines, powertrains, and related components, all designed to meet the demanding requirements of commercial and industrial applications.

Cummins Solenoid O-Ring Part 3903577 Compatibility

The Solenoid O-Ring part number 3903577 is designed to fit seamlessly with a range of Cummins engines, ensuring a reliable seal and preventing leaks. This part is crucial for maintaining the integrity of the engine’s solenoid system, which is integral to the engine’s operation.

Engine Compatibility

-

4B3.9 Engine Series

- The Solenoid O-Ring part 3903577 is specifically engineered to fit the 4B3.9 engine series. This engine is known for its robust performance and reliability, often used in various industrial and commercial applications. The O-Ring ensures that the solenoid components remain sealed, which is vital for the engine’s efficiency and longevity.

-

6B5.9 Engine Series

- Similarly, the 6B5.9 engine series benefits from the use of the Solenoid O-Ring part 3903577. This engine is another high-performance model, frequently utilized in heavy-duty applications. The O-Ring’s precision fit helps maintain the necessary pressure and seal within the solenoid system, contributing to the engine’s overall performance and durability.

Importance of the Solenoid O-Ring

The Solenoid O-Ring part 3903577 plays a critical role in the functionality of the solenoid system in both the 4B3.9 and 6B5.9 engines. By providing a tight seal, it prevents the escape of fluids and gases, which can lead to system failures and reduced engine efficiency. This part is essential for maintaining the operational integrity of the engine’s solenoid components, ensuring that they function correctly and reliably over time.

Role of Part 3903577 Solenoid O-Ring in Engine Systems

The 3903577 Solenoid O-Ring is an essential component in ensuring the efficient and reliable operation of various engine systems. Its primary function is to create a seal within the solenoid assembly, preventing leaks and maintaining system integrity.

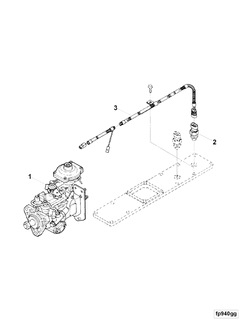

Fuel Injection Pump

In the fuel injection pump, the Solenoid O-Ring plays a significant role by sealing the solenoid valve. This ensures that fuel is delivered precisely and consistently to the engine’s combustion chambers. The seal provided by the O-Ring helps maintain the required fuel pressure and prevents any fuel leakage, which could otherwise lead to inefficient fuel delivery and potential engine performance issues.

Fuel Pump

Within the fuel pump system, the Solenoid O-Ring is integral to the operation of the solenoid-controlled valves. These valves regulate the flow of fuel from the pump to the engine. A reliable seal ensures that the fuel pump can maintain consistent pressure and flow rates, which are vital for the engine’s smooth operation. The O-Ring’s sealing properties help in preventing fuel contamination and ensuring that the fuel system operates within specified parameters.

General Pump Applications

Across various pump applications, the Solenoid O-Ring is used to seal solenoid-operated valves that control fluid flow. Whether it’s in a fuel system or another type of pump, the O-Ring ensures that the solenoid functions correctly without leaks. This is particularly important in high-pressure systems where even a small leak can lead to significant performance degradation.

Fuel System Integrity

In the broader context of the fuel system, the Solenoid O-Ring contributes to the overall integrity and efficiency of fuel delivery. By ensuring that solenoids operate within sealed environments, the O-Ring helps maintain the precise control of fuel flow and pressure. This is essential for optimal engine performance, fuel efficiency, and emissions control.

Conclusion

The 3903577 Solenoid O-Ring, though small, plays a substantial role in the reliable operation of engine systems by ensuring that solenoids function correctly and maintain the necessary seals to prevent leaks and maintain system pressure. Regular maintenance and proper installation are key to maximizing the performance and longevity of this critical component.

-

Dixon, J. (2010). Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.