This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

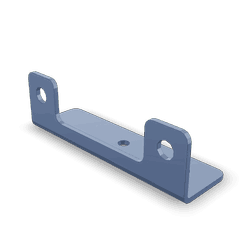

The 3394215 Solenoid Bracket is a component manufactured by Cummins, a well-established name in the commercial truck industry. This bracket is designed for use in commercial trucks, where it plays a supportive role in the vehicle’s electrical system. Cummins is renowned for producing reliable and high-performance parts, and the 3394215 Solenoid Bracket is no exception, offering a solution for securely mounting solenoids in various truck models.

Basic Concepts of Solenoid Brackets

A solenoid bracket serves as a mounting point for solenoids within a truck’s electrical system. Solenoids are electromechanical devices that convert electrical energy into mechanical motion, often used to control various functions such as gear shifting or fuel injection. The bracket ensures that the solenoid is held firmly in place, allowing it to operate efficiently and interact correctly with other electrical components 1.

Purpose of the 3394215 Solenoid Bracket

The 3394215 Solenoid Bracket is specifically designed to mount and secure solenoids in commercial trucks. By providing a stable attachment point, it ensures that the solenoid remains in the correct position and orientation, which is vital for the proper functioning of the electrical system. This Cummins part plays a role in maintaining the integrity of the solenoid’s connections and protecting it from physical damage or vibration that could otherwise affect its performance 2.

Key Features

The 3394215 Solenoid Bracket is constructed from durable materials, ensuring it can withstand the rigors of commercial truck operation. Its design includes features such as precise mounting holes and secure attachment points, which facilitate easy and accurate installation. Additionally, the bracket may incorporate corrosion-resistant coatings or treatments to enhance its longevity in various operating environments 3.

Benefits

Utilizing the 3394215 Solenoid Bracket offers several advantages. Its robust construction contributes to improved durability, reducing the likelihood of failure under stress. The design of the bracket also simplifies the installation process, allowing for quick and straightforward attachment of the solenoid. Furthermore, by providing a stable mounting solution, the bracket helps to ensure the optimal performance of the solenoid it supports 4.

Installation Process

Installing the 3394215 Solenoid Bracket involves several steps to ensure proper attachment and function. First, the appropriate location for the bracket should be identified on the truck. Using the provided hardware, the bracket is then secured in place. It is important to follow the manufacturer’s instructions regarding torque specifications to avoid over-tightening, which could damage the bracket or the solenoid. Once the bracket is installed, the solenoid can be mounted, ensuring all electrical connections are secure and correctly aligned.

Troubleshooting Common Issues

Common issues with solenoid brackets may include loose connections, corrosion, or physical damage. If the solenoid is not functioning correctly, it is advisable to inspect the bracket for any signs of wear or damage. Ensuring that all connections are tight and free from corrosion can often resolve performance issues. In cases where the bracket itself is damaged, replacement may be necessary to restore proper function.

Maintenance Tips

To ensure the longevity and optimal performance of the 3394215 Solenoid Bracket, regular maintenance is recommended. This includes inspecting the bracket for signs of wear or damage, ensuring that all connections remain secure, and cleaning the area around the bracket to prevent the buildup of dirt or debris. Additionally, applying a corrosion-resistant coating periodically can help protect the bracket from environmental factors.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the commercial truck industry. The company’s extensive product range and commitment to customer satisfaction make it a preferred choice for commercial vehicle operators and maintenance professionals.

Compatibility with Cummins Engines

The Solenoid Bracket part number 3394215, manufactured by Cummins, is designed to be compatible with a range of Cummins engines. This bracket is crucial for the proper installation and functioning of solenoids within these engines. Here’s how it fits with the specified engines:

G8.3 and G8.3 CM558

The Solenoid Bracket 3394215 is engineered to fit seamlessly with the G8.3 and G8.3 CM558 engines. This bracket ensures that the solenoids are securely mounted, which is essential for maintaining the integrity of the engine’s electrical and control systems.

GTA8.3 CM558

Similar to the G8.3 and G8.3 CM558 engines, the GTA8.3 CM558 engine also benefits from the use of the Solenoid Bracket 3394215. This bracket is designed to provide a robust mounting solution for solenoids, ensuring that they are positioned correctly and securely within the engine’s architecture.

QSL9 G CM558

The Solenoid Bracket 3394215 is also compatible with the QSL9 G CM558 engine. This bracket plays a vital role in the engine’s operation by providing a reliable mounting point for solenoids, which are integral to the engine’s control and performance systems.

By ensuring that solenoids are properly mounted, the Solenoid Bracket 3394215 contributes to the overall reliability and efficiency of these Cummins engines.

Role of Part 3394215 Solenoid Bracket in Engine Systems

The 3394215 Solenoid Bracket is an integral component in the assembly and operation of engine systems, particularly in relation to accessories and electric starting mechanisms.

Integration with Accessories

In engine systems, the solenoid bracket secures the solenoid to the engine block or another stable mounting point. This ensures that the solenoid remains in a fixed position, allowing it to effectively engage with various accessories. The stable mounting provided by the bracket allows for consistent and reliable operation of accessories such as alternators, fuel pumps, and other peripheral devices. The bracket’s role in maintaining the solenoid’s position is essential for the efficient transfer of electrical signals that activate these accessories.

Function in Electric Starting

The solenoid bracket plays a significant role in the electric starting system of an engine. When the ignition key is turned, the solenoid receives an electrical signal. The bracket ensures that the solenoid is correctly aligned and securely mounted, enabling it to transmit this signal to the starter motor. This transmission is vital for the starter motor to engage the flywheel, initiating the engine’s cranking process. The secure mounting provided by the bracket prevents any misalignment or movement of the solenoid, which could otherwise lead to inefficient or failed starting attempts.

Overall System Reliability

By providing a stable and secure mounting solution for the solenoid, the 3394215 Solenoid Bracket contributes to the overall reliability and performance of the engine system. Its role in both accessory integration and electric starting underscores its importance in maintaining the smooth and efficient operation of the engine.

Conclusion

The 3394215 Solenoid Bracket is a critical component in the electrical systems of commercial trucks, ensuring the secure and efficient operation of solenoids. Its robust construction, ease of installation, and compatibility with various Cummins engines make it a valuable part for maintaining the reliability and performance of truck electrical systems.

-

Gilles, Tim. Automotive Service: Inspection, Maintenance, Repair: 2nd Edition. Cengage Learning, 2020.

↩ -

Isermann, Rolf. Combustion Engine Diagnosis. Springer Vieweg, 2017.

↩ -

Reif, Konrad (Ed.). Brakes Brake Control and Driver Assistance Systems Function Regulation and Components. Springer, 2014.

↩ -

Ribbens, William B. Understanding Automotive Electronics. Elsevier Science, 2003.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.