This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

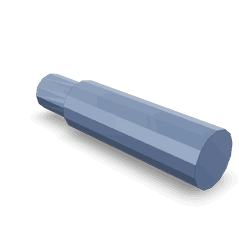

The Cummins 3376022 Solenoid Valve Seat Install Tool is a specialized instrument designed for the precise installation and maintenance of solenoid valve seats in heavy-duty trucks. This tool is integral to ensuring the proper function and longevity of solenoid valves, which are vital components in the operation of truck engines 1.

Basic Concepts

Solenoid valves are electromechanical devices that control the flow of fluids or gases in a system. In heavy-duty trucks, they play a role in various systems, including fuel injection, emissions control, and engine management 2. The solenoid valve seat is a component that ensures the valve operates correctly by providing a secure and precise location for the valve to open and close. The integrity and proper seating of the solenoid valve are important for the efficient operation of these systems 3.

Purpose and Function

The Cummins 3376022 is designed to facilitate the installation and maintenance of solenoid valve seats. It ensures that the valve seat is correctly positioned and secured, which is important for the valve’s operation and the overall performance of the engine. By using this tool, technicians can achieve accurate and consistent installation, which contributes to the longevity and reliability of the solenoid valves.

Key Features

The Cummins 3376022 is characterized by its robust design and the use of high-quality materials. It features precision-machined components that ensure accurate seating of the valve. The tool is ergonomically designed for ease of use, reducing the physical strain on technicians during installation procedures.

Benefits

Utilizing the Cummins 3376022 offers several advantages. It enhances the efficiency of the installation process, reduces the time required for maintenance, and contributes to the overall performance of the engine. The tool’s precision also minimizes the risk of installation errors, which can lead to valve malfunction and engine issues.

Installation Process

When using the Cummins 3376022, it is important to follow a systematic approach. Begin by ensuring the engine is cool and the system is depressurized. Clean the installation area to remove any debris that could affect the seating of the valve. Position the tool over the valve seat and use it to install the seat with the recommended torque specifications. After installation, verify the seat’s position and ensure there are no obstructions to the valve’s operation.

Troubleshooting and Maintenance

In the event of issues with solenoid valve seats, the Cummins 3376022 can be used to remove and reinstall the seat as necessary. Regular maintenance of the tool itself is also important; this includes cleaning it after use and storing it in a dry place to prevent corrosion. Following these practices helps maintain the tool’s effectiveness and longevity.

Safety Considerations

When using the Cummins 3376022, it is important to adhere to safety practices. This includes wearing appropriate personal protective equipment, ensuring the work area is well-ventilated, and following all manufacturer guidelines and safety protocols. These measures help protect technicians from potential hazards associated with engine maintenance.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins plays a significant role in the automotive and heavy-duty truck industry. The company’s dedication to customer satisfaction is reflected in the design and production of its automotive components, including the Cummins 3376022 Solenoid Valve Seat Install Tool.

Conclusion

The Cummins 3376022 Solenoid Valve Seat Install Tool is an essential component in the maintenance and installation of solenoid valve seats in heavy-duty trucks. Its precise design and robust construction ensure the efficient operation of solenoid valves, contributing to the overall performance and reliability of truck engines. Technicians benefit from its ease of use and the precision it offers, which minimizes installation errors and enhances engine performance. Regular maintenance of the tool and adherence to safety practices are crucial for its longevity and effectiveness in engine maintenance procedures.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.