4919951

Salvage Sleeve

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction to Salvage Sleeves

Salvage sleeves, also known as liner sleeves, are crucial in the maintenance and repair of commercial truck engines. These sleeves are designed to restore the internal diameter of a cylinder bore that has been compromised by wear, corrosion, or other damage. By inserting a new sleeve into the bore, engineers and mechanics can effectively extend the life of the engine without the need for a complete overhaul, ensuring continued reliability and performance 1.

The Role of Cummins 4919951 Salvage Sleeve

The Cummins 4919951 Salvage Sleeve is a high-quality component specifically engineered for use in Cummins engines. This part is designed to fit seamlessly within the engine’s cylinder bore, providing a smooth and durable surface that reduces friction and wear. The 4919951 Salvage Sleeve plays a critical role in maintaining the operational efficiency and longevity of the engine, ensuring that the truck continues to perform reliably under demanding conditions 2.

How a Salvage Sleeve Works

A salvage sleeve functions by being inserted into the worn cylinder bore of an engine. The sleeve is typically made from a high-strength material that can withstand the high pressures and temperatures found within the engine. Once installed, the sleeve provides a new, smooth surface for the piston rings to seal against, reducing oil consumption and improving overall engine performance. The installation process involves precise measurements and careful fitting to ensure that the sleeve is properly aligned and seated within the bore 3.

Importance of the Cummins 4919951 Salvage Sleeve in Truck Operations

The Cummins 4919951 Salvage Sleeve is essential for maintaining the performance and reliability of commercial trucks. By replacing worn or damaged cylinder bores with a new sleeve, engineers and mechanics can significantly extend the lifespan of the engine. This not only reduces the need for costly engine rebuilds or replacements but also ensures that the truck remains operational and efficient, minimizing downtime and maintenance costs.

Troubleshooting and Maintenance

Proper maintenance of the Cummins 4919951 Salvage Sleeve is crucial for ensuring its longevity and effectiveness. Regular inspections should be conducted to check for signs of wear, damage, or improper installation. If any issues are detected, it is important to address them promptly to prevent further damage to the engine. Additionally, using high-quality lubricants and following the manufacturer’s recommended maintenance schedule can help to prolong the life of the sleeve and the engine as a whole.

Cummins: A Leader in Engine Manufacturing

Cummins is a renowned manufacturer of engines and related components for commercial trucks and heavy-duty vehicles. With a strong commitment to quality and innovation, Cummins has established itself as a trusted name in the industry. The company’s extensive range of products, including the 4919951 Salvage Sleeve, are designed to meet the rigorous demands of commercial truck operations, providing reliable performance and durability.

Conclusion

The Cummins 4919951 Salvage Sleeve is a vital component in the maintenance and repair of commercial truck engines. By understanding the role and importance of this part, engineers, mechanics, and fleet operators can ensure that their vehicles remain in optimal condition, reducing downtime and maintenance costs. Proper installation and maintenance of the salvage sleeve are essential for maximizing the performance and longevity of the engine, making it a critical investment for any commercial truck operation.

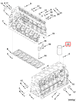

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.