3070486

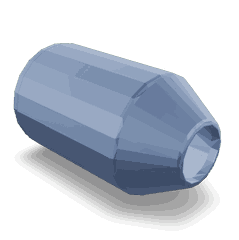

Injector Sleeve

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins Injector Sleeve (Part #3070486) is a component designed to support the operation of heavy-duty trucks. It plays a role in the fuel injection system by ensuring the proper alignment and sealing of fuel injectors. This part contributes to the efficient and reliable performance of the engine, making it a significant element in the maintenance and operation of heavy-duty vehicles 1.

Basic Concepts of Injector Sleeves

An injector sleeve is a cylindrical component that houses the fuel injector within the engine cylinder. Its function is to provide a secure and precise fit for the injector, allowing for accurate fuel delivery into the combustion chamber. The sleeve contributes to the overall performance of the engine by maintaining the integrity of the fuel injection process, which is vital for combustion efficiency and engine power 2.

Purpose of the Cummins Injector Sleeve

The Cummins Injector Sleeve serves to maintain the alignment and sealing of the fuel injector within the engine. By securing the injector in place, it ensures that fuel is delivered consistently and accurately into the combustion chamber. This alignment is crucial for the injector to function correctly, which in turn affects the engine’s performance, fuel efficiency, and emissions 3.

Key Features

The Cummins Injector Sleeve is constructed from durable materials that can withstand the high pressures and temperatures of the fuel injection system. Its design specifications include precise dimensions to ensure a snug fit within the engine cylinder. Unique attributes of this sleeve may include enhanced sealing properties and resistance to wear, which contribute to its performance and longevity.

Benefits of Using Cummins Injector Sleeves

Utilizing Cummins Injector Sleeves can lead to improved engine efficiency due to the precise alignment and sealing they provide. This can result in reduced wear and tear on the fuel injectors and other related components. Additionally, the enhanced performance of the fuel injection system may contribute to better fuel economy, making it a valuable component for heavy-duty truck operations.

Installation Process

Installing the Cummins Injector Sleeve requires careful attention to detail to ensure proper fit and function. The process involves removing the old sleeve, cleaning the cylinder, and inserting the new sleeve with the correct orientation. Best practices include using the appropriate tools and following manufacturer guidelines to avoid common pitfalls such as misalignment or improper sealing.

Common Issues and Troubleshooting

Injector sleeves may encounter issues such as wear, leaks, or misalignment over time. Troubleshooting these problems involves inspecting the sleeve for signs of damage or deterioration, ensuring it is correctly installed, and addressing any leaks in the fuel system. Regular maintenance and timely replacement can help prevent these issues and ensure optimal performance.

Maintenance Tips

To maintain Cummins Injector Sleeves, it is advisable to conduct regular inspections for wear or damage. Cleaning the sleeves according to manufacturer recommendations can prevent buildup that may affect performance. Knowing when to replace the sleeves is also important; signs such as decreased engine performance or fuel leaks may indicate the need for replacement.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins serves a wide range of industries, including heavy-duty trucking. The company’s product range includes engines, powertrains, and related components, all of which are known for their reliability and performance in demanding applications.

Compatibility of Injector Sleeve Part 3070486 with Cummins Engines

The Injector Sleeve part 3070486, manufactured by Cummins, is designed to fit a variety of Cummins engines. This part is integral to the proper functioning of the engine’s fuel injection system, ensuring efficient and reliable performance. Below is a detailed breakdown of the engines with which this part is compatible:

L10 Series Engines

- L10 CELECT

- L10 GAS

- L10 MECHANICAL

The Injector Sleeve part 3070486 is compatible with all variants of the L10 series engines, including those equipped with CELECT technology, GAS, and MECHANICAL systems. This compatibility ensures that the sleeve fits seamlessly into the engine’s architecture, providing a secure and efficient seal for the injector.

M11 Series Engines

- M11 CELECT

- M11 CELECT PLUS

- M11 MECHANICAL

Similar to the L10 series, the M11 series engines also support the Injector Sleeve part 3070486. This part is designed to work with both CELECT and CELECT PLUS technologies, as well as the standard MECHANICAL versions. The compatibility ensures that the sleeve meets the specific requirements of each engine variant, maintaining optimal performance.

N14 Series Engines

- N14 CELECT

- N14 CELECT PLUS

- N14 MECHANICAL

The N14 series engines, including CELECT, CELECT PLUS, and MECHANICAL versions, are also compatible with the Injector Sleeve part 3070486. This part is engineered to fit these engines, ensuring that the injector operates efficiently and reliably across different configurations.

Other Cummins Engines

- ISM CM570

- QSM11 CM570

- NH/NT 855

The Injector Sleeve part 3070486 is also compatible with the ISM CM570, QSM11 CM570, and NH/NT 855 engines. This compatibility extends to various configurations within these engine models, ensuring that the sleeve fits properly and functions as intended.

By ensuring compatibility with a wide range of Cummins engines, the Injector Sleeve part 3070486 provides a versatile solution for maintaining and repairing these engines. This compatibility is crucial for technicians and fleet managers who need to ensure that their engines continue to operate efficiently and reliably.

Role of Part 3070486 Injector Sleeve in Engine Systems

The injector sleeve, identified by part number 3070486, is an integral component in the fuel injection system of an engine. It serves as a conduit for the fuel injector, ensuring a precise and consistent delivery of fuel into the combustion chamber. This part interfaces directly with the cylinder head, often referred to as the top-level assembly (TLA) head or cylinder (top level assembly) head, to maintain the integrity of the fuel injection process.

When the fuel injector activates, it sprays fuel through the injector sleeve into the combustion chamber. The sleeve’s design helps to atomize the fuel, enhancing combustion efficiency. This is particularly important in high-performance engines where precise fuel delivery can significantly impact engine performance and emissions.

The injector sleeve also plays a role in managing the thermal environment around the injector. By providing a stable mounting point, it helps to dissipate heat away from the injector, prolonging its lifespan and maintaining optimal performance. This is especially relevant in engines equipped with performance parts or those that have undergone an emissions rebuild, where thermal management is key to achieving both power and efficiency.

In engines with advanced fuel systems, the injector sleeve is part of a more complex injector plumbing setup. This includes connections to the fuel rail and other components that regulate fuel pressure and flow. The sleeve ensures that these connections are secure and that the fuel path remains unobstructed, which is vital for the consistent operation of the engine.

Furthermore, the injector sleeve interacts with other critical engine components such as the camshaft, connecting rod and piston, and the crosshead. The camshaft controls the timing of the fuel injection, while the connecting rod and piston work in tandem to compress the air-fuel mixture in the cylinder. The crosshead, often found in high-performance or specialized engines, may also interface with the injector sleeve to optimize the fuel delivery process.

In summary, the injector sleeve (part 3070486) is a fundamental component that ensures the reliable and efficient delivery of fuel in engine systems. Its interaction with the cylinder head, fuel injection system, and other engine components underscores its importance in maintaining engine performance and efficiency.

Conclusion

The Cummins Injector Sleeve (Part #3070486) is a critical component in the fuel injection system of heavy-duty engines. Its role in ensuring the proper alignment and sealing of fuel injectors contributes to the efficient and reliable performance of the engine. By understanding the key features, benefits, and installation process of this part, technicians and fleet managers can maintain optimal engine performance and efficiency.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.