3165112

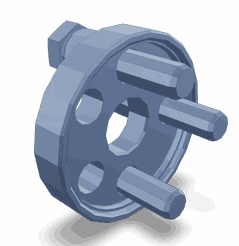

Crankshaft Wear Sleeve Installer

Cummins®

IN STOCK

1 is currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Crankshaft Wear Sleeve Installer (3165112) by Cummins is a specialized tool designed to facilitate the installation of crankshaft wear sleeves in heavy-duty truck engines. Its purpose is to ensure precise and secure placement of wear sleeves, which are critical components in maintaining the integrity and performance of the engine. By providing a reliable method for installing these sleeves, the tool helps in preserving the engine’s efficiency and longevity 1.

Basic Concepts

Crankshaft wear sleeves are cylindrical components placed over the crankshaft journals to restore or maintain the proper diameter. These sleeves play a role in engine maintenance by compensating for wear and tear that occurs over time, thus ensuring the crankshaft maintains its original specifications 2. Proper installation of these sleeves is necessary to avoid issues such as misalignment, which can lead to increased friction, wear, and potential engine failure.

Functionality of the Crankshaft Wear Sleeve Installer

The Crankshaft Wear Sleeve Installer operates by providing a controlled and consistent method for pressing wear sleeves onto the crankshaft journals. The installation process involves positioning the installer over the journal, aligning it with the wear sleeve, and then using hydraulic or mechanical force to press the sleeve into place. This tool interacts with other engine components by ensuring that the sleeves are installed with the correct interference fit, which is vital for the sleeves to function effectively and withstand the operational stresses of the engine 3.

Role in Truck Operation

The significance of the Crankshaft Wear Sleeve Installer in truck operation lies in its ability to ensure smooth and efficient engine performance. By facilitating the correct installation of wear sleeves, the tool helps in reducing downtime associated with engine repairs and maintenance. This, in turn, enhances the overall reliability of the truck, allowing for consistent performance and extended operational life of the engine.

Key Features

The 3165112 Crankshaft Wear Sleeve Installer is characterized by its design and construction features, which include high-quality materials and precision engineering. These attributes ensure durability and accuracy during the installation process. The tool is designed for ease of use, allowing technicians to perform installations efficiently and with minimal risk of error.

Benefits

Using the Cummins Crankshaft Wear Sleeve Installer provides several advantages. It contributes to extended engine life by ensuring that wear sleeves are installed correctly, which helps in maintaining the engine’s performance over time. Additionally, the tool improves the overall efficiency of the maintenance process, making it a cost-effective solution for engine upkeep.

Troubleshooting and Maintenance

Common issues that may arise with crankshaft wear sleeves and the installer include misalignment and improper fit. Regular maintenance practices, such as inspecting the tool for wear and ensuring it is clean and free of debris, can help in preventing these issues. Additionally, following the manufacturer’s guidelines for installation can ensure optimal performance and longevity of both the sleeves and the installer.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation in engine technology, Cummins has established a strong reputation in the automotive and heavy-duty truck industries. The company is committed to advancing technology and providing reliable, high-performance solutions for its customers.

Role of Part 3165112 Crankshaft Wear Sleeve Installer in Engine Systems

The Part 3165112 Crankshaft Wear Sleeve Installer is an essential tool within the Service Tool Kit for addressing specific maintenance and repair tasks on engine systems. This installer is designed to facilitate the precise fitting of crankshaft wear sleeves, which are used to repair worn crankshaft journals without the need for a complete crankshaft replacement.

When integrated into engine maintenance procedures, the installer ensures that the wear sleeves are correctly positioned and securely pressed onto the crankshaft journals. This process is vital for restoring the crankshaft’s original dimensions and surface finish, thereby enhancing the engine’s performance and longevity.

In conjunction with other tools and components within the service toolkit, such as micrometers for measuring journal wear, honing stones for surface preparation, and torque wrenches for securing components, the crankshaft wear sleeve installer plays a significant role. It allows mechanics and engineers to perform in-situ crankshaft repairs, reducing downtime and costs associated with engine overhauls.

The installer’s application is typically followed by thorough inspections using borescopes to verify the integrity of the installed sleeves and ensure there are no imperfections that could lead to future failures. Additionally, the use of this tool is often accompanied by the application of high-quality engine oils and coolants to protect the newly repaired crankshaft and surrounding components.

Conclusion

Overall, the Part 3165112 Crankshaft Wear Sleeve Installer is a valuable asset in the toolkit of any professional engaged in engine maintenance and repair, providing a means to efficiently and effectively address crankshaft wear issues.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.