This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

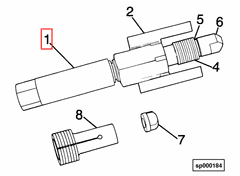

The Nut, Injection Sleeve Puller (Part #3377089) by Cummins is a specialized tool designed for the maintenance and repair of diesel engines. Its purpose is to facilitate the removal and replacement of injection sleeves, which are components in the fuel injection system of diesel engines. This tool ensures that maintenance procedures are carried out efficiently and effectively, contributing to the overall performance and longevity of the engine.

Basic Concepts

Injection sleeve pullers are tools used in diesel engine maintenance to remove and replace injection sleeves. These sleeves are part of the fuel injection system and are responsible for delivering fuel into the combustion chamber at precise moments. Over time, injection sleeves may wear out or become damaged, necessitating their removal and replacement. The Nut, Injection Sleeve Puller (Part #3377089) is designed to perform this task with precision and ease, ensuring that the process is both efficient and safe 1.

Purpose and Function

The Nut, Injection Sleeve Puller (Part #3377089) is specifically designed to remove injection sleeves from diesel engines. It operates by gripping the nut that secures the injection sleeve in place and applying force to extract it. This tool ensures that the removal process is carried out without damaging surrounding components, which is vital for maintaining the integrity of the fuel injection system. By facilitating the proper removal and replacement of injection sleeves, this tool contributes to the efficient functioning of the fuel injection system and, by extension, the overall performance of the diesel engine 2.

Key Features

The Nut, Injection Sleeve Puller (Part #3377089) boasts several key features that enhance its effectiveness. Its design is robust, ensuring durability and reliability during use. The tool is constructed from high-quality materials that can withstand the rigors of engine maintenance. Additionally, it features a precise gripping mechanism that securely holds the nut, allowing for efficient and safe removal of the injection sleeve. These characteristics make the Nut, Injection Sleeve Puller (Part #3377089) an invaluable tool for diesel engine maintenance 3.

Benefits

Using the Nut, Injection Sleeve Puller (Part #3377089) offers several benefits. It improves the efficiency of maintenance procedures by simplifying the removal and replacement of injection sleeves. This leads to reduced downtime for engines undergoing maintenance, which is particularly beneficial in commercial and industrial settings. Furthermore, the tool enhances safety during engine repairs by minimizing the risk of damage to surrounding components. Proper maintenance of injection sleeves using this tool can also contribute to prolonged engine lifespan, as it ensures that the fuel injection system operates optimally 4.

Troubleshooting and Maintenance

When using the Nut, Injection Sleeve Puller (Part #3377089), it is important to be aware of common issues that may arise. These can include difficulties in gripping the nut or challenges in applying sufficient force to remove the injection sleeve. To troubleshoot these issues, ensure that the tool is correctly positioned and that the gripping mechanism is fully engaged. Regular maintenance of the tool, such as cleaning and inspecting for wear, is also crucial to ensure its continued effectiveness. Storing the tool in a dry, secure location when not in use will help prevent damage and ensure optimal performance 5.

Cummins Overview

Cummins Inc. is a global leader in the design, manufacture, and distribution of engines and related technologies. With a history spanning over a century, Cummins has established a reputation for producing high-quality automotive components and solutions. The company is committed to innovation and excellence, ensuring that its products meet the demanding requirements of the automotive industry. The Nut, Injection Sleeve Puller (Part #3377089) is a testament to Cummins’ dedication to providing reliable and effective tools for engine maintenance and repair.

Role of Part 3377089 Nut, Inj Sleeve Puller in Engine Systems

The part 3377089 Nut, Inj Sleeve Puller is a component in the maintenance and repair of engine systems, specifically when dealing with the removal of injector sleeves. This nut is designed to interface with the injector sleeve remover, facilitating the extraction process of worn or damaged injector sleeves from the engine block.

When an injector sleeve needs to be replaced due to wear, damage, or as part of a routine maintenance procedure, the injector sleeve remover is employed. The 3377089 Nut plays a role in this process by securely fitting onto the injector sleeve remover tool. This fitment ensures that the tool can apply the necessary force to dislodge the injector sleeve from the engine block without causing damage to surrounding components.

The effectiveness of the 3377089 Nut in this application relies on its precise engineering. It must be able to withstand the forces involved in pulling an injector sleeve out of an engine block, which can be substantial. The nut’s design allows for a secure connection to the injector sleeve, ensuring that the removal process is smooth and efficient.

Conclusion

In summary, the 3377089 Nut, Inj Sleeve Puller is a specialized component that enhances the functionality of the injector sleeve remover tool. Its role in facilitating the safe and effective removal of injector sleeves is vital for the maintenance and repair of engine systems, ensuring that engines operate efficiently and reliably.

-

Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body, David C Barton and John D Fieldhouse, Elsevier, 2009

↩ -

Automotive Mechatronics, Konrad Reif, Springer Vieweg, 2015

↩ -

Automotive Braking Systems CDX Master Automotive Technician Series, Nicholas Goodnight and Kirk VanGelder, Jones Bartlett Learning, 2019

↩ -

Brakes Brake Control and Driver Assistance Systems Function Regulation and Components, Konrad Reif Ed, Springer, 2014

↩ -

ISB/ISD6.7 CM2150 B120, Bulletin Number 4358473, Fault Code Troubleshooting Manual

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.