This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3027635 Sleeve is a specialized component designed for use in heavy-duty truck engines. Its purpose is to enhance the durability and performance of the engine by providing a protective and supportive role within the engine assembly. This part is integral to maintaining the operational integrity of the engine, ensuring efficient and reliable performance over extended periods.

Basic Concepts of a Sleeve

In the context of engine components, a sleeve refers to a cylindrical component that lines the cylinder bore of an engine. Its primary function is to provide a wear-resistant surface that allows for smooth piston movement 1. The sleeve integrates within the engine assembly by fitting into the cylinder block, where it supports the piston and piston rings. This integration helps in reducing friction and wear, contributing to the overall efficiency and longevity of the engine.

Purpose of the 3027635 Sleeve

The Cummins 3027635 Sleeve plays a specific role in the operation of a truck engine by offering a durable and wear-resistant surface for the piston to move against. This part interacts with other engine components such as the piston rings and cylinder walls, ensuring a tight seal and efficient combustion process. Its design helps in dissipating heat and reducing the wear on the cylinder walls, which is crucial for maintaining engine performance and reliability 2.

Key Features

The Cummins 3027635 Sleeve is characterized by several key features that enhance its performance and durability. These include a high-quality material composition, typically involving a heat-treated alloy that provides excellent wear resistance and thermal conductivity. The design of the sleeve incorporates precise tolerances to ensure a proper fit within the cylinder bore. Additionally, unique attributes such as honing patterns on the sleeve’s surface improve the seal between the piston rings and the cylinder wall, contributing to better engine efficiency 3.

Benefits

The advantages provided by the Cummins 3027635 Sleeve include improved engine performance, increased longevity, and enhanced reliability. By reducing friction and wear on the cylinder walls, the sleeve helps in maintaining optimal engine efficiency. Its durable construction ensures that the engine can withstand high stress and thermal loads, leading to a longer service life. Furthermore, the sleeve contributes to consistent engine performance, reducing the likelihood of unexpected failures.

Installation Process

Proper installation of the Cummins 3027635 Sleeve involves several steps to ensure correct fitting and optimal performance. The process begins with preparing the cylinder bore by cleaning it thoroughly to remove any debris or old sleeve material. The sleeve is then carefully inserted into the bore, ensuring it is aligned correctly. Tools such as a sleeve driver may be required to press the sleeve into place without damaging it. Best practices include verifying the sleeve’s fit and ensuring there are no gaps or misalignments that could affect engine performance.

Common Issues and Troubleshooting

Typical problems associated with the Cummins 3027635 Sleeve may include improper fitting, wear, or damage to the sleeve surface. Diagnostic methods involve inspecting the sleeve for signs of wear, checking the fit within the cylinder bore, and assessing the condition of the piston rings. Troubleshooting tips include ensuring the sleeve is correctly installed, addressing any misalignments, and replacing the sleeve if significant wear or damage is detected. Regular inspections can help in identifying issues early and preventing more severe engine problems.

Maintenance Tips

To prolong the life of the Cummins 3027635 Sleeve, regular maintenance practices are recommended. This includes routine inspections to check for wear or damage, ensuring the sleeve remains properly fitted within the cylinder bore. Cleaning procedures should be performed to remove any buildup of carbon or debris that could affect the sleeve’s performance. Adhering to manufacturer-recommended inspection intervals and maintenance schedules will help in maintaining the sleeve’s condition and ensuring the engine operates efficiently.

Performance Enhancements

The Cummins 3027635 Sleeve contributes to overall engine efficiency and performance by providing a durable and wear-resistant surface for the piston to move against. This results in reduced friction and wear, leading to more consistent engine operation. Potential upgrades or modifications that can be made include using higher-quality materials for the sleeve or incorporating advanced coatings to further enhance wear resistance and thermal conductivity. These enhancements can lead to improved engine performance and longevity.

Cummins Overview

Cummins Inc. is a well-established company with a rich history in the heavy-duty truck industry. Founded in 1919, Cummins has grown to become a global leader in the design, manufacturing, and distribution of diesel and natural gas engines, as well as related technologies. The company’s product range includes engines, filtration systems, powertrains, and emission solutions, all designed to meet the demanding requirements of heavy-duty applications. Cummins is renowned for its commitment to quality, innovation, and customer satisfaction, making it a trusted name in the industry.

Role of Part 3027635 Sleeve in Engine Systems

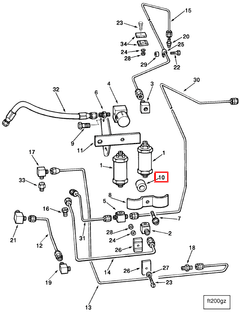

The part 3027635 Sleeve is an essential component in various engine systems, facilitating the smooth operation of several key elements.

In the valve system, the Sleeve ensures precise alignment and movement of the valves, contributing to efficient valve operation and maintaining the integrity of the valve seals. This is vital for the proper intake and exhaust processes within the engine.

Within the fuel system, the Sleeve plays a part in the accurate delivery of fuel by ensuring that fuel lines and injectors are correctly positioned. This alignment is important for maintaining fuel efficiency and reducing the risk of fuel leaks.

In the plumbing system, the Sleeve aids in the secure fitting of various pipes and hoses, which is essential for the circulation of coolants, oils, and other fluids. Proper fitting prevents leaks and ensures that fluids reach their intended destinations without obstruction.

The rocker housing cover and rocker housing mounting cover both benefit from the Sleeve’s role in providing a stable and secure mounting point. This stability is important for the operation of the rocker arms, which are responsible for transferring motion from the camshaft to the valves.

Lastly, in the valve covers, the Sleeve helps in maintaining a seal around the valve train components. This seal is important for preventing oil leaks and contaminants from entering the engine, thus preserving the cleanliness and efficiency of the engine’s internal components.

Conclusion

The Cummins 3027635 Sleeve is a vital component in heavy-duty truck engines, contributing to their durability, performance, and reliability. Its design and features ensure efficient engine operation, reduced wear, and enhanced longevity. Proper installation, regular maintenance, and understanding its role within various engine systems are crucial for maximizing the benefits of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.