This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 215300 Sleeve is a component designed for use in commercial truck engines, playing a significant role in their operation. This part is manufactured by Cummins Inc., a well-established name in the industry known for its quality and innovation in engine technology. Understanding the function and importance of this Cummins part is key to maintaining and optimizing the performance of commercial trucks.

Basic Concepts of a Sleeve

In the context of engine components, a sleeve refers to a cylindrical part that lines the inside of an engine’s cylinder. Sleeves are integral to the engine’s operation, providing a smooth surface for the piston to move against. They are typically made from durable materials to withstand the high pressures and temperatures within the engine. Sleeves interact closely with pistons, piston rings, and coolant passages, contributing to the engine’s overall efficiency and longevity 1.

Purpose of the 215300 Sleeve

The 215300 Sleeve serves a specific function within the engine of a commercial truck. It is designed to enhance the engine’s performance and durability by providing a wear-resistant surface inside the cylinder. This reduces friction between the piston and the cylinder wall, which can lead to improved engine efficiency and reduced wear on other components. The sleeve also plays a role in maintaining the engine’s structural integrity under high stress conditions 2.

Key Features

The 215300 Sleeve is characterized by its design and material properties. It is crafted from high-quality materials that offer excellent resistance to wear and corrosion. The sleeve’s design ensures a precise fit within the engine cylinder, which is crucial for optimal engine performance. Its unique attributes contribute to enhanced functionality and longevity, making it a reliable component for commercial truck engines 3.

Benefits

The advantages of using the 215300 Sleeve in a truck engine include improved engine efficiency, reduced wear on other engine components, and enhanced overall performance. By providing a durable and smooth surface for the piston to move against, the sleeve helps to minimize friction and heat generation within the engine. This can lead to more efficient fuel consumption and longer engine life.

Installation Process

Proper installation of the 215300 Sleeve is vital for ensuring optimal performance and longevity. The installation process involves carefully fitting the sleeve into the engine cylinder, ensuring it is aligned correctly and securely in place. Attention to detail during installation is important to avoid issues such as misalignment or improper seating, which could affect engine performance.

Common Issues and Troubleshooting

Typical problems associated with the 215300 Sleeve may include wear, corrosion, or improper installation. Diagnosing these issues often involves a thorough inspection of the sleeve and surrounding components. Repairs or replacements may be necessary to restore the engine’s performance. Regular maintenance and inspections can help identify potential issues before they become significant problems.

Maintenance Tips

To ensure the longevity and efficiency of the 215300 Sleeve, regular maintenance practices are recommended. This includes routine inspections for signs of wear or damage, as well as ensuring the sleeve is properly installed and aligned. Following the manufacturer’s guidelines for maintenance and replacement can help maintain the engine’s performance and extend the life of the sleeve.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its commitment to quality and innovation. The company offers a wide range of engine technologies and components, including the 215300 Sleeve. Cummins’ history of excellence and its focus on advancing engine technology have established it as a trusted name in the industry. The company’s dedication to quality is evident in its products, which are designed to meet the demanding requirements of commercial truck applications.

Role of Part 215300 Sleeve in Engine Systems

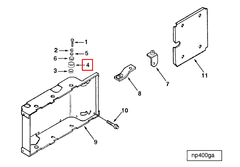

The part 215300 Sleeve is instrumental in ensuring the seamless operation of various engine components. It is specifically designed to interface with the Noise Panel and the Noise Panel Rear Sum, facilitating efficient noise reduction and structural integrity within the engine system.

Interaction with Noise Panel

In the context of the Noise Panel, the 215300 Sleeve acts as a connector that ensures a secure fit and proper alignment. This is essential for maintaining the acoustic properties of the panel, which is designed to reduce engine noise. The sleeve’s precise dimensions and material properties help in absorbing vibrations and minimizing noise transmission, thereby contributing to a quieter engine operation.

Integration with Noise Panel Rear Sum

When integrated with the Noise Panel Rear Sum, the 215300 Sleeve plays a significant role in enhancing the structural stability of the rear sump area. This component is often subjected to high levels of stress and vibration, and the sleeve helps in distributing these forces evenly. Additionally, it aids in sealing the rear sump, preventing any potential leaks that could compromise engine performance and safety.

Overall Functionality

Overall, the 215300 Sleeve is a key component in the engine’s noise reduction system. Its role extends beyond mere connection; it ensures that the Noise Panel and Noise Panel Rear Sum function optimally, contributing to both the acoustic and structural aspects of the engine system. Engineers and mechanics should pay close attention to the proper installation and maintenance of this sleeve to ensure the longevity and efficiency of the engine components it supports.

Conclusion

The 215300 Sleeve by Cummins is a critical component in the operation and maintenance of commercial truck engines. Its design and material properties contribute to improved engine efficiency, reduced wear on other components, and enhanced overall performance. Proper installation, regular maintenance, and understanding its role in the engine system are essential for maximizing the benefits of this part.

-

Parikyan, T. (Ed.). (2022). Advances in Engine and Powertrain Research and Technology. Springer Nature.

↩ -

Lakshminarayanan, P. A., & Kumar, A. (2020). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature.

↩ -

Gilles, T. (2020). Automotive Service: Inspection, Maintenance, Repair: 2nd Edition. Cengage Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.