This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

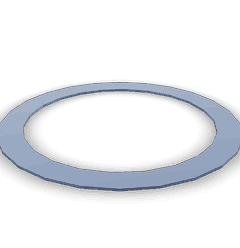

The Cummins 3070714 Shim is a specialized component designed for use in heavy-duty truck operations. Its primary role is to provide precise spacing, alignment, and adjustment within various engine components, ensuring optimal performance and efficiency. Understanding the function and application of this shim is vital for maintaining and enhancing the operational integrity of heavy-duty trucks.

Basic Concepts of Shims

Shims are thin, often washer-like spacers used in mechanical systems to fill small gaps, provide precise alignment, and facilitate fine adjustments. They are commonly made from materials such as steel, aluminum, or plastic, chosen for their durability and ability to withstand mechanical stress. In automotive and heavy-duty applications, shims play a role in ensuring components operate within specified tolerances, thereby contributing to the overall efficiency and longevity of the system 1.

Purpose of the 3070714 Shim

The Cummins 3070714 Shim is specifically engineered to address the need for precise spacing and alignment in heavy-duty truck engines. It is applied in critical engine components where exact clearances are necessary for optimal performance. By providing the correct spacing, the shim helps maintain the intended clearances between moving parts, reducing wear and enhancing the efficiency of the engine 2.

Key Features

The Cummins 3070714 Shim is characterized by several key features that enhance its functionality. It is constructed from high-quality materials, ensuring durability and resistance to wear. The shim’s thickness is precisely engineered to meet the specific requirements of its application, allowing for fine-tuned adjustments. Additionally, its design may include features such as chamfered edges to facilitate easy installation and removal, and a smooth surface to prevent damage to mating components 3.

Benefits of Using the Cummins 3070714 Shim

Utilizing the Cummins 3070714 Shim offers several advantages. It provides improved precision in mechanical adjustments, ensuring that engine components operate within the manufacturer’s specified tolerances. This precision contributes to enhanced durability and reliability of the truck’s engine, reducing the likelihood of premature wear or failure. Furthermore, the shim’s design and material composition support consistent performance under the demanding conditions typical of heavy-duty truck operations 4.

Installation and Usage

Proper installation of the Cummins 3070714 Shim is critical to achieving the desired performance outcomes. The process involves selecting the appropriate shim thickness for the application, ensuring a clean and undamaged installation surface, and carefully placing the shim between the components it is designed to separate. Tools such as torque wrenches may be required to secure components in place, following the manufacturer’s guidelines for torque specifications to avoid over-tightening or under-tightening 5.

Troubleshooting and Maintenance

Common issues with the Cummins 3070714 Shim may include improper fit, damage during installation, or wear over time. Troubleshooting involves verifying the shim’s thickness and fit, inspecting for signs of damage, and ensuring it is correctly installed. Maintenance practices include regular inspection of the shim and its mating surfaces for wear or damage, and replacement as necessary to maintain optimal performance. Adhering to these practices helps prolong the lifespan of the shim and ensures consistent engine performance 6.

Manufacturer Information - Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins has established itself as a trusted name in the automotive industry, known for its commitment to quality, innovation, and customer satisfaction. The company’s expertise in diesel engines and components is reflected in the design and performance of products like the Cummins 3070714 Shim, underscoring its dedication to enhancing the efficiency and reliability of heavy-duty truck operations 7.

Shim Part 3070714 Compatibility with Cummins Engines

The Shim part 3070714, manufactured by Cummins, is designed to fit a variety of Cummins engines, ensuring proper alignment and performance. This shim is crucial for maintaining the integrity of engine components and ensuring smooth operation. Below is a detailed overview of its compatibility with specific Cummins engines:

K-Series Engines

- K19: The shim part 3070714 is engineered to fit seamlessly with the K19 engine, providing the necessary clearance and alignment between moving parts.

- K38: For the K38 engine, this shim ensures that the engine components are correctly positioned, enhancing overall engine performance and longevity.

- K50: The K50 engine also benefits from the precise fit of the shim part 3070714, which helps in maintaining the correct spacing between engine parts.

L-Series Engines

- L10 MECHANICAL: The L10 MECHANICAL engine utilizes the shim part 3070714 to ensure that all mechanical components are properly aligned, contributing to the engine’s efficiency and reliability.

M-Series Engines

- M11 CELECT PLUS: The M11 CELECT PLUS engine incorporates the shim part 3070714 to maintain the precise alignment of its components, ensuring optimal performance.

- M11 MECHANICAL: Similarly, the M11 MECHANICAL engine relies on this shim to achieve the correct spacing and alignment, enhancing the engine’s operational efficiency.

N-Series Engines

- N14 MECHANICAL: The N14 MECHANICAL engine uses the shim part 3070714 to ensure that all parts are correctly positioned, which is essential for maintaining the engine’s performance and durability.

NH/NT Series Engines

- NH/NT 855: The NH/NT 855 engine also benefits from the shim part 3070714, which helps in achieving the necessary alignment and clearance between engine components, ensuring smooth and efficient operation.

Each of these engines, despite their different specifications and applications, relies on the precise fit and function of the shim part 3070714 to maintain optimal performance and longevity 8.

Role of Part 3070714 Shim in Engine Systems

Part 3070714 Shim is an integral component in the fine-tuning and maintenance of various engine systems. Its application ensures optimal performance and efficiency across a range of critical assemblies and sub-systems. Here’s how it integrates with the provided components:

Aftercooler Assembly

In the aftercooler assembly, the shim plays a role in maintaining precise clearances between moving parts. This ensures efficient cooling of the compressed air, which is vital for the performance and longevity of the engine 9.

Calibration

During the calibration process, the shim is used to achieve the exact tolerances required for sensors and actuators. This precision is essential for accurate readings and responses within the engine control system 10.

Fuel Systems

Fuel Pump

In the fuel pump, the shim ensures that the pump components operate within their designed parameters, facilitating consistent fuel delivery and pressure 11.

Fuel Base Pump and Top-Level Assembly Pump

For both the fuel base pump and the top-level assembly pump, the shim helps in maintaining the necessary clearances, which are critical for the smooth operation and reliability of the fuel system 12.

Fuel Filter and Damper

Within the fuel filter and damper assembly, the shim assists in keeping the filter elements aligned and the damper functioning correctly, which is important for fuel quality and system stability 13.

Emissions Rebuild Kit

In an emissions rebuild kit, the shim is used to ensure that emission control components, such as valves and sensors, are properly aligned and operate within specified tolerances, contributing to reduced emissions and compliance with regulations 14.

Engine Installation Kit

During engine installation, the shim is employed to ensure that all components are correctly aligned and clearances are maintained, which is essential for a successful and trouble-free installation 15.

On Board Spares Kit

In the on board spares kit, the shim is included to facilitate quick and accurate repairs, ensuring that replacement parts fit correctly and function as intended 16.

Engine Cooling System

Within the engine cooling system, the shim helps in maintaining the proper gaps between components, ensuring efficient heat transfer and preventing overheating 17.

Fuel Injection System

In the fuel injection system, the shim is critical for the precise operation of injectors, ensuring that fuel is delivered in the correct quantities and at the right times, which is essential for engine performance and fuel efficiency 18.

Spare Parts Kit

The shim is a valuable component in the spare parts kit, providing the necessary adjustments to ensure that replacement parts fit and function correctly, minimizing downtime and maintenance costs 19.

By integrating part 3070714 Shim into these systems, engineers and mechanics can achieve the fine-tuned performance and reliability required for modern engines.

Conclusion

The Cummins 3070714 Shim is a critical component in the maintenance and optimization of heavy-duty truck engines. Its precise design and application ensure that engine components operate within specified tolerances, contributing to enhanced performance, durability, and efficiency. Proper installation, maintenance, and understanding of its role in various engine systems are essential for maximizing the benefits of this Cummins part.

-

Hilgers, M., & Achenbach, W. (2021). Vocational Vehicles and Applications. Springer Vieweg.

↩ -

Majewski, A., & Jaskelainen, H. (2023). Diesel Emissions and Their Control: Second Edition. SAE International.

↩ -

Drozdziel, P. (2023). The Vehicle Diesel Engine Startup Process Operational and Environmental Aspects. Routledge.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 4388664, QSK95 CM2350 K113.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 4388664, QSK95 CM2350 K113.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 4388664, QSK95 CM2350 K113.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 4388664, QSK95 CM2350 K113.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 4388664, QSK95 CM2350 K113.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 4388664, QSK95 CM2350 K113.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 4388664, QSK95 CM2350 K113.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 4388664, QSK95 CM2350 K113.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 4388664, QSK95 CM2350 K113.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 4388664, QSK95 CM2350 K113.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 4388664, QSK95 CM2350 K113.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 4388664, QSK95 CM2350 K113.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 4388664, QSK95 CM2350 K113.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 4388664, QSK95 CM2350 K113.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 4388664, QSK95 CM2350 K113.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 4388664, QSK95 CM2350 K113.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.