This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

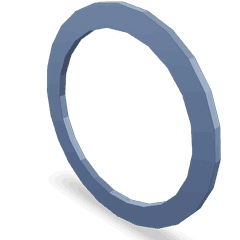

Shims are thin, often wedge-shaped washers used in mechanical applications to fill small gaps, provide support, and ensure proper clearances and alignments between components. The Cummins Part #101842 Shim is a specialized component designed for use in heavy-duty truck engines, playing a significant role in maintaining the precise alignment and clearance necessary for optimal engine performance 1.

Basic Concepts of Shims

Shims function by providing the necessary space between two mating parts to achieve the desired fit and alignment. In mechanical systems, shims are crucial for ensuring that components operate within their specified tolerances, which helps in reducing wear, preventing excessive friction, and maintaining efficient operation 2. They are commonly made from materials like steel, aluminum, or plastic, chosen for their durability and ability to withstand operational stresses.

Purpose of the Cummins Part #101842 Shim

The Cummins Part #101842 Shim is specifically designed to address clearance and alignment issues within the engine components of heavy-duty trucks. It plays a role in the precise fitting of parts, ensuring that engine components operate smoothly and efficiently. This shim is particularly important in applications where even minor misalignments can lead to significant performance issues or increased wear on engine parts 3.

Key Features

The Cummins Part #101842 Shim is characterized by several key features that enhance its functionality. It is made from a durable material that can withstand the high stresses and temperatures encountered in heavy-duty truck engines. The shim’s thickness is carefully calibrated to provide the exact clearance needed for optimal engine performance. Additionally, its design may include features that prevent it from shifting out of place once installed, ensuring long-term reliability.

Benefits of Using the Cummins Part #101842 Shim

Using the Cummins Part #101842 Shim offers several advantages. It contributes to improved engine performance by ensuring that components are properly aligned and have the correct clearance. This can lead to reduced wear and tear on engine parts, enhancing the overall reliability and longevity of the truck’s engine. Furthermore, the precise fitting provided by this shim can help in maintaining efficient engine operation, potentially leading to better fuel efficiency and reduced maintenance costs 4.

Installation and Usage Guidelines

To install the Cummins Part #101842 Shim, it is important to follow a systematic approach. Begin by identifying the area where the shim is needed, ensuring that the engine is cool and the components are clean. Use the appropriate tools to carefully place the shim between the mating parts, ensuring it is correctly aligned and seated. It is advisable to consult the engine’s service manual for specific instructions related to the engine model in question. After installation, perform a thorough inspection to confirm that the shim is properly placed and that the components operate smoothly.

Troubleshooting Common Issues

Common issues with shims include improper clearance or alignment, which can lead to increased wear or engine performance issues. If problems arise, it is important to carefully inspect the shim and the mating components for signs of wear or damage. Ensure that the shim is the correct thickness and material for the application. If necessary, replace the shim with a new one that meets the specified requirements. Regular inspections and maintenance can help in identifying and addressing issues before they lead to significant problems.

Maintenance Tips

Regular maintenance checks are important to ensure the Cummins Part #101842 Shim continues to function correctly. Inspect the shim and surrounding components during routine engine maintenance, looking for signs of wear, damage, or misalignment. Follow the manufacturer’s guidelines for inspection intervals and replacement. Keeping the engine clean and free of debris can also help in maintaining the integrity of the shim and the components it supports.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable, high-performance engines and components. The company’s extensive product range and commitment to innovation and quality have made it a preferred choice for heavy-duty truck manufacturers and operators worldwide.

Role of Part 101842 Shim in Engine Systems

Part 101842 Shim is integral to the precise operation of various engine components, ensuring optimal performance and efficiency. Its application spans across several key systems:

AFC-VS/TMD and Calibrations

The AFC-VS/TMD system relies on the shim to maintain accurate fuel delivery and timing. By ensuring the proper alignment and clearance, the shim helps in achieving the desired calibrations, which are essential for the engine’s performance metrics.

Fuel Pump and Related Components

In the fuel pump system, part 101842 Shim plays a significant role in maintaining the integrity of fuel delivery. It ensures that the fuel pump operates within specified tolerances, which is vital for consistent fuel pressure and flow. This, in turn, affects the overall fuel efficiency and engine performance.

Fuel Calibration and Codes

Accurate fuel calibration is dependent on the precise fitting of components, where the shim ensures that there is no undue stress or misalignment. This is particularly important in systems that require specific fuel codes and calibrations to function correctly. The shim helps in maintaining the exact specifications needed for optimal fuel mixture and combustion.

Fuel Pump Housing and Gasket Set

Within the fuel pump housing, the shim ensures that the gasket set is properly seated. This is essential for preventing leaks and ensuring that the fuel pump housing maintains a sealed environment, which is critical for the pump’s operation and the engine’s fuel supply system.

Fuel Rating Dummy Option

In systems where a fuel rating dummy option is used, the shim ensures that the dummy component is correctly positioned. This is important for diagnostic purposes and for maintaining the integrity of the fuel system’s performance data.

Various Pump Codes

The shim is also used in conjunction with different pump codes (e.g., CPL 0003, CPL 59, CPL-11, etc.) to ensure that each pump variant operates within its designed parameters. This is essential for the compatibility and performance of the fuel pump across different engine configurations.

Conclusion

In summary, the Cummins Part #101842 Shim is a fundamental component in ensuring the precise operation and compatibility of various engine systems, contributing to the overall efficiency and reliability of the engine. Regular maintenance and proper installation are key to maximizing the benefits of this part.

-

Ribbens, W. B. (2003). Understanding Automotive Electronics. Elsevier Science.

↩ -

Robert Bosch GmbH. (2007). Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition. Springer Vieweg.

↩ -

Sheng, G. (2012). Vehicle Noise, Vibration and Sound Quality. SAE International.

↩ -

Gilles, T. (2020). Automotive Service: Inspection, Maintenance, Repair: 2nd Edition. Cengage Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.