This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3255000 Debris Shield is a component designed to safeguard critical engine components in heavy-duty trucks from road debris and environmental contaminants. Its role is integral to maintaining the operational integrity and efficiency of the engine, ensuring that it performs reliably under various conditions 1.

Purpose and Function

The primary purpose of the Debris Shield is to protect vital engine components from damage caused by road debris, dust, and other environmental contaminants. By creating a barrier between these elements and the engine, the debris shield contributes to the overall efficiency and longevity of the engine. This protection helps prevent premature wear and tear, reducing the likelihood of costly repairs and downtime 2.

Key Features

The Debris Shield is engineered with several key features that enhance its performance and durability. Its design incorporates robust materials that can withstand harsh operating conditions. The shield is crafted to fit precisely around the engine components it protects, ensuring comprehensive coverage. Additionally, unique attributes such as corrosion-resistant coatings and impact-absorbing materials are utilized to further enhance its effectiveness 3.

Benefits

Utilizing the Debris Shield offers several benefits. It provides improved engine protection, which can lead to reduced maintenance costs over time. The shield enhances the reliability of the engine, particularly in harsh operating conditions, by minimizing the risk of damage from external contaminants. This results in a more consistent and dependable performance from the engine 4.

Installation and Compatibility

Proper installation of the Debris Shield is crucial for its effectiveness. Installation procedures should follow manufacturer guidelines to ensure a secure fit and optimal protection. The shield is compatible with various Cummins engine models and is designed to integrate seamlessly with these systems. It is also suitable for use with other relevant truck makes and models, providing versatile protection across different applications 5.

Maintenance and Troubleshooting

Routine maintenance of the Debris Shield is important to ensure its continued effectiveness. Regular inspections should be conducted to check for any signs of damage or wear. Cleaning the shield to remove accumulated debris is also recommended. If any issues are identified, such as cracks or significant wear, prompt attention is advised to prevent further damage to the engine components 6.

Performance in Various Conditions

The Debris Shield is designed to perform effectively under a range of operating conditions. Whether facing extreme temperatures, heavy loads, or off-road environments, the shield provides consistent protection for the engine. Its effectiveness in challenging situations helps maintain engine performance and longevity, even in the most demanding applications 7.

Customer Reviews and Feedback

Customer feedback on the Debris Shield highlights its effectiveness in protecting engines from debris and contaminants. Many users report satisfaction with the shield’s durability and the peace of mind it provides in harsh operating conditions. While some users have noted minor issues, such as the need for careful installation, the overall consensus is positive regarding its performance and value 8.

Manufacturer Information

Cummins Inc. is a renowned manufacturer in the automotive and heavy-duty truck industry, known for its commitment to producing high-quality components. With a history of innovation and a strong reputation for reliability, Cummins focuses on delivering products that meet the demanding needs of its customers. The company’s dedication to customer satisfaction is evident in the design and performance of the Debris Shield 9.

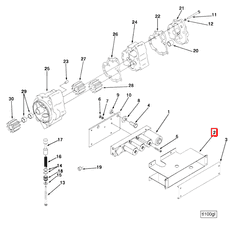

Role of Part 3255000 Debris Shield in Engine Systems

The Debris Shield is an essential component in safeguarding various engine systems from external contaminants. Its integration with these systems ensures optimal performance and longevity.

Integration with Control Systems

When paired with control systems, the Debris Shield protects sensitive electronic components from dust, dirt, and other particulates. This is particularly important for the Throttle Control and Electronic Engine Control systems, where even minor contaminants can lead to malfunctions or reduced efficiency.

Compatibility with ETR Engine

In the ETR Engine setup, the Debris Shield works in conjunction with the Throttle Lever and Governor to maintain a clean operating environment. This helps in preserving the precision of throttle responses and governor functions, thereby ensuring consistent engine performance.

Role in M.U.T.C. and Multi Unit Throttle Control

For the M.U.T.C. (Multi Unit Throttle Control) and Electronic Multi Unit Throttle Control systems, the Debris Shield acts as a first line of defense. It prevents debris from interfering with the intricate mechanisms and electronic sensors, which are vital for synchronized operation across multiple engine units.

Protective Function in EBM: Shield and Rock Systems

In systems like the EBM: Shield and Rock, where mechanical components are exposed to harsh environments, the Debris Shield offers an additional layer of protection. This is essential for maintaining the integrity of these components and ensuring they function as intended.

Overall System Protection

Across all these systems, the Debris Shield contributes to a cleaner, more reliable operation. By minimizing the risk of contamination, it helps in reducing maintenance requirements and enhancing the overall efficiency of the engine systems.

Conclusion

The Cummins 3255000 Debris Shield is a vital component for protecting heavy-duty truck engines from environmental contaminants and debris. Its robust design, compatibility with various engine systems, and the benefits it offers in terms of engine longevity and reliability make it an invaluable part of the engine’s defense system. Proper installation, maintenance, and understanding of its role in different engine systems are key to maximizing its effectiveness.

-

Robert Bosch GmbH. (2014). Bosch Automotive Handbook 9th Edition. Robert Bosch GmbH.

↩ -

Quansheng Zhan, Shengbo Eben, Li Kun Deng. (2018). Automotive Heating Ventilation and Air Conditioning. Jones Bartlett Learning.

↩ -

Matthew Huang. (2002). Vehicle Crash Dynamics. CRC Press.

↩ -

Rolf Isermann. (2017). Combustion Engine Diagnosis. Springer Vieweg.

↩ -

Cummins Inc. (n.d.). Owners Manual. Bulletin Number 5411322.

↩ -

Cummins Inc. (n.d.). Owners Manual. Bulletin Number 5411322.

↩ -

Cummins Inc. (n.d.). Owners Manual. Bulletin Number 5411322.

↩ -

Cummins Inc. (n.d.). Owners Manual. Bulletin Number 5411322.

↩ -

Cummins Inc. (n.d.). Owners Manual. Bulletin Number 5411322.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.