This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3254122 Rock Shield is a protective component designed for heavy-duty trucks. Its primary role is to safeguard various truck components from the impact of rocks and debris, which can occur during off-road or rugged terrain driving. This shield contributes to the overall durability and reliability of the truck by minimizing the risk of damage to critical parts 1.

Purpose and Functionality

The Cummins 3254122 Rock Shield serves to protect truck components from the impact of rocks and debris. By acting as a barrier, it helps prevent damage to undercarriage parts, exhaust systems, and other vulnerable areas. This protection is vital for maintaining the integrity of the truck’s components, ensuring they operate efficiently and last longer 2. The shield plays a role in reducing the frequency of repairs and downtime, thereby contributing to the truck’s overall performance and longevity.

Key Features

The Cummins 3254122 Rock Shield is engineered with specific design and material characteristics to enhance its performance and longevity. It is typically made from durable materials that can withstand impacts and harsh environmental conditions. The shield’s design may include features such as a robust frame, flexible material to absorb impacts, and secure attachment points to ensure it remains in place during operation. These attributes contribute to its effectiveness in protecting the truck’s undercarriage 3.

Benefits

The advantages provided by the Cummins 3254122 Rock Shield include reduced maintenance costs, extended component life, and improved truck performance. By protecting critical components from damage, the shield helps lower the frequency of repairs and replacements. This, in turn, can lead to cost savings over the truck’s operational life. Additionally, the shield contributes to maintaining the truck’s performance by ensuring that protected components operate within their designed parameters 4.

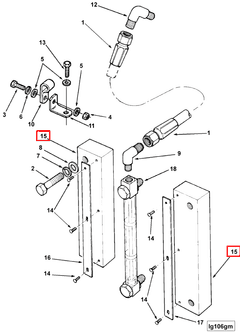

Installation Process

Proper installation of the Cummins 3254122 Rock Shield involves several steps to ensure it is securely and effectively positioned. Begin by identifying the correct location for the shield on the truck’s undercarriage. Follow the manufacturer’s instructions for attaching the shield, which may involve using bolts, brackets, or other fastening methods. It is important to ensure that the shield is level and securely fastened to prevent it from shifting during operation. Common pitfalls to avoid during installation include improper alignment, insufficient fastening, and failure to follow the manufacturer’s guidelines.

Maintenance and Troubleshooting

Regular maintenance checks for the Cummins 3254122 Rock Shield involve inspecting it for signs of damage, such as cracks, bends, or loose fastenings. If any damage is detected, it may be necessary to repair or replace the shield to maintain its protective function. Troubleshooting common issues may involve tightening loose fasteners, replacing damaged sections, or readjusting the shield’s position. Signs that may indicate the need for replacement include significant damage to the shield or repeated impacts that compromise its integrity.

Compatibility and Application

The Cummins 3254122 Rock Shield is designed for specific types of trucks and engine models. Its applicability varies based on the truck’s make, model, and the conditions in which it operates. The shield is intended for use in environments where the risk of rock and debris impact is high, such as off-road or construction sites. Understanding the shield’s compatibility with your truck is important for ensuring it provides the intended protection.

Manufacturer Overview - Cummins

Cummins Inc. is a leading manufacturer in the automotive industry, known for its commitment to quality and innovation in truck components. With a history of producing reliable and high-performance parts, Cummins has established a reputation for excellence. The company’s product range includes engines, filtration systems, and aftermarket parts, all designed to meet the demanding requirements of heavy-duty applications. Cummins’ dedication to quality is evident in its rigorous testing and manufacturing processes, ensuring that its components, including the 3254122 Rock Shield, deliver reliable performance and durability.

Cummins Rock Shield Part 3254122 in Engine Applications

The Cummins Rock Shield part number 3254122 is a critical component designed to protect the engine from debris and rocks that can be encountered during operation. This part is essential for maintaining the integrity of the engine by preventing foreign objects from causing damage.

N14 MECHANICAL Engines

The N14 MECHANICAL engine series by Cummins benefits significantly from the Rock Shield part 3254122. This engine is known for its robust design and is widely used in heavy-duty applications such as construction and mining equipment. The Rock Shield ensures that the engine remains shielded from potential hazards, thereby extending its operational life and maintaining performance.

Grouping of Engines

While the Rock Shield part 3254122 is specifically mentioned for the N14 MECHANICAL engines, it is worth noting that similar protective measures are often employed across various Cummins engine models. These engines, which include the C15, QSK19, and others, all share the commonality of operating in environments where debris and rocks are prevalent. The Rock Shield part is tailored to fit these engines, providing a consistent level of protection across different models.

Importance of the Rock Shield

The Rock Shield part 3254122 is integral to the engine’s overall protection strategy. Its placement and design are meticulously engineered to ensure that it effectively deflects debris and rocks, thereby safeguarding the engine’s vital components. This part is a testament to Cummins’ commitment to durability and reliability in their engine designs.

Role of Part 3254122 Rock Shield in Engine Systems

The 3254122 Rock Shield is an essential component in safeguarding various engine systems from potential damage caused by debris, rocks, and other foreign objects. Its strategic placement and robust design ensure optimal protection for several key components.

Integration with Engine Bay Components

-

Oil Pan Protection: The Rock Shield is mounted in a position that offers direct protection to the oil pan. This is particularly important as the oil pan houses the engine’s lubricant, which is vital for reducing friction and wear within the engine. By shielding the oil pan from impacts, the Rock Shield helps maintain the integrity of the oil system, ensuring consistent lubrication and preventing oil leaks.

-

Gauge and Sensor Safeguarding: In many engine configurations, the Rock Shield is positioned to protect sensitive gauges and sensors, such as the Engine Bay Module (EBM) gauge and oil level sensors. These components are critical for monitoring the engine’s performance and health. The shield prevents damage from flying debris, ensuring accurate readings and reliable operation of these sensors.

-

Mounting Stability: The Rock Shield is designed to be securely mounted within the engine bay. Its mounting points are engineered to withstand the vibrations and stresses of engine operation while providing a stable barrier against impacts. This stability is essential for the shield to effectively perform its protective role without compromising the structural integrity of the engine bay.

-

Comprehensive Debris Defense: Beyond specific components, the Rock Shield contributes to the overall defense mechanism of the engine bay. It acts as a first line of defense against a variety of debris, reducing the risk of damage to adjacent components such as wiring harnesses, fuel lines, and other undercarriage parts. This comprehensive protection helps in maintaining the engine’s efficiency and longevity.

Conclusion

In summary, the 3254122 Rock Shield plays a significant role in enhancing the durability and reliability of engine systems by providing essential protection to critical components and ensuring the smooth operation of the engine.

-

Eret, Angelina. Dynamic and Fatigue Assessment of Heavy-Duty Engine Valves. Springer Nature, 2024.

↩ -

ElSayed, Mohamed PE. Fundamentals of Integrated Vehicle Realization. SAE International, 2017.

↩ -

Kluczyk, Barry. How to Rebuild Any Automotive Engine. CarTech, 2008.

↩ -

Robert Bosch GmbH. Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition. Springer Vieweg, 2007.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.