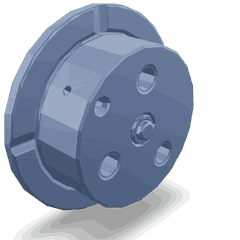

5484100

Idler Shaft

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 5484100 Idler Shaft is a component manufactured by Cummins, a well-established name in the automotive industry, particularly in the realm of diesel engines and heavy-duty truck parts. This Cummins part is integral to the operation of heavy-duty trucks, contributing to the efficiency and reliability of the vehicle’s drivetrain system.

Basic Concepts of Idler Shafts

An idler shaft is a mechanical component used in various systems to maintain tension in a belt or chain, or to redirect the path of a drive mechanism. In the context of a truck’s drivetrain, the idler shaft helps in the smooth transfer of power by ensuring that the components remain properly aligned and that the drive belt or chain operates under the correct tension. This is vital for the efficient operation of the vehicle 1.

Role of the 5484100 Idler Shaft in Truck Operation

The 5484100 Idler Shaft plays a specific role in the operation of heavy-duty trucks by maintaining the correct tension and alignment of the drive belt within the engine’s accessory drive system. It interacts with other components such as the crankshaft and various engine accessories, ensuring that power is transferred efficiently from the engine to these accessories. This contributes to the overall performance and reliability of the truck 2.

Key Features of the 5484100 Idler Shaft

The 5484100 Idler Shaft is designed with several features that enhance its functionality and durability. It is constructed from high-quality materials that can withstand the rigors of heavy-duty truck operation. The shaft incorporates precision-engineered bearings that allow for smooth rotation and reduced friction. Additionally, its design may include unique elements such as reinforced housings or specialized coatings to further improve its performance and longevity.

Benefits of Using the 5484100 Idler Shaft

Utilizing the 5484100 Idler Shaft in heavy-duty trucks can lead to several advantages. It contributes to improved efficiency within the drivetrain system, which can translate to better overall truck performance. The reduced wear on other components due to proper tension and alignment can lead to extended service intervals and lower maintenance costs. Furthermore, the durability of the idler shaft can result in potential cost savings for fleet operators over time 3.

Installation and Integration

Proper installation of the 5484100 Idler Shaft is crucial for its effective operation. It requires adherence to manufacturer guidelines, which may include specific prerequisites and the use of appropriate tools. The installation process involves ensuring that the shaft is correctly aligned and secured within the truck’s drivetrain, following a series of steps to integrate it seamlessly with other components.

Maintenance and Troubleshooting

Routine maintenance of the 5484100 Idler Shaft is important for its longevity and optimal performance. This may involve regular inspections for signs of wear or damage, lubrication of moving parts, and replacement of worn components as necessary. Common issues that may arise include misalignment or bearing failure, which can often be addressed through troubleshooting steps such as realigning the shaft or replacing faulty bearings.

Performance and Efficiency

The 5484100 Idler Shaft contributes to the overall performance and efficiency of the truck by ensuring that the drivetrain operates smoothly and under the correct tension. This can have a positive impact on fuel economy and the reliability of the drivetrain system, as well as the longevity of other components within the system.

Cummins: Manufacturer Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes diesel and natural gas engines, as well as related technologies. With a history of innovation and a strong commitment to quality, Cummins has established itself as a trusted name in the automotive industry. The company’s expertise in diesel engine manufacturing and its dedication to advancing technology have made it a preferred choice for heavy-duty truck components, including the 5484100 Idler Shaft.

Idler Shaft (Part 5484100) Compatibility with Cummins Engines

The Idler Shaft part number 5484100, manufactured by Cummins, is designed to fit seamlessly with a range of Cummins engines. This part plays a role in the engine’s operation by maintaining the proper tension of the timing belt or chain, ensuring smooth and efficient engine performance.

ISX15 CM2250 SN

The ISX15 CM2250 SN engine is one of the models that benefit from the Idler Shaft part 5484100. This engine is known for its robust performance and reliability, making it a popular choice in various applications. The Idler Shaft ensures that the timing components operate correctly, contributing to the engine’s longevity and efficiency.

QSX15 CM2350 X105

The QSX15 CM2350 X105 engine is another model that is compatible with the Idler Shaft part 5484100. This engine is designed for heavy-duty applications, providing substantial power and durability. The Idler Shaft is essential in maintaining the precise timing required for the engine’s optimal performance.

X15 CM2350 X116B and X15 CM2350 X123B

Both the X15 CM2350 X116B and X15 CM2350 X123B engines are part of the same engine family and share many components, including the Idler Shaft part 5484100. These engines are engineered for high performance and reliability, making them suitable for demanding applications. The Idler Shaft ensures that the timing mechanism functions correctly, preventing potential engine issues.

X15 CM2450 X134B

The X15 CM2450 X134B engine is another model that is compatible with the Idler Shaft part 5484100. This engine is designed to deliver exceptional power and efficiency, making it a top choice for various applications. The Idler Shaft is crucial in maintaining the proper tension of the timing components, ensuring the engine runs smoothly and efficiently.

Role of Part 5484100 Idler Shaft in Engine Systems

The idler shaft, designated as part 5484100, is an integral component in the timing system of an engine. It operates in conjunction with the camshaft and crankshaft to ensure the precise synchronization of the engine’s valves and pistons.

In the engine block, the idler shaft is positioned to maintain tension in the timing chain or belt, which connects the crankshaft and camshaft. This tension is vital for the smooth and reliable operation of the valve train. Without adequate tension, the timing chain or belt could slip, leading to incorrect valve timing and potential engine damage.

The idler shaft also plays a role in reducing wear and noise within the engine. By properly aligning the timing chain or belt, it minimizes friction between moving parts. This alignment helps in distributing the load evenly across the chain or belt, which in turn extends the lifespan of these components.

In engines with multiple cylinders, the idler shaft ensures that the timing between cylinders remains consistent. This consistency is essential for balanced engine performance, as it ensures that each cylinder fires at the correct moment in the combustion cycle.

Overall, the idler shaft is a key element in maintaining the intricate timing relationships within the engine, contributing to efficient and reliable operation.

Conclusion

The 5484100 Idler Shaft is a critical component in the operation of heavy-duty trucks, particularly those equipped with Cummins engines. Its role in maintaining the correct tension and alignment of the drive belt or chain ensures efficient power transfer and contributes to the overall performance and reliability of the vehicle. With its high-quality construction, precision-engineered features, and compatibility with a range of Cummins engines, this Cummins part is a valuable asset for fleet operators seeking to optimize their truck’s performance and minimize maintenance costs.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.