This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

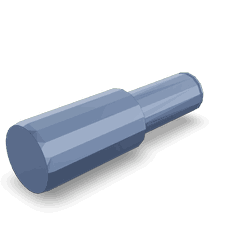

The Cummins 3681701 Barring Shaft is a component designed for use in heavy-duty truck engines. Its purpose is to facilitate the rotation of the engine’s crankshaft without the need for combustion. This function is significant during engine startup and maintenance procedures, ensuring that the engine components are properly aligned and lubricated before operation 1.

Basic Concepts of Barring Shafts

A barring shaft is a tool used in internal combustion engines to manually rotate the crankshaft. This rotation allows for the inspection and maintenance of engine components, as well as ensuring that the engine is free from obstructions prior to startup. The barring shaft operates by engaging with the flywheel or a designated slot on the crankshaft, providing a means to turn the engine over without ignition 2.

Purpose of the 3681701 Barring Shaft

The Cummins 3681701 Barring Shaft plays a specific role in the operation of a truck engine. It is used during engine startup to ensure that the crankshaft rotates smoothly, which helps in aligning the pistons and valves correctly. Additionally, it is employed during maintenance procedures to manually turn the engine, allowing technicians to inspect internal components and perform necessary adjustments or repairs 3.

Key Features

The Cummins 3681701 Barring Shaft is constructed with several key features that enhance its performance and durability. It is made from high-strength materials to withstand the rigors of engine operation. The design includes precise machining to ensure a snug fit within the engine’s components, and it may feature anti-friction coatings to reduce wear during use. These characteristics contribute to the shaft’s reliability and longevity 1.

Benefits

The use of the Cummins 3681701 Barring Shaft provides several benefits. It contributes to improved engine longevity by ensuring proper alignment and lubrication during startup. Reduced wear and tear on engine components is another advantage, as the shaft allows for gentle rotation without the stress of combustion. Additionally, it enhances reliability during engine startups by facilitating smooth crankshaft rotation 2.

Installation Process

Installing the Cummins 3681701 Barring Shaft requires careful attention to detail. Begin by ensuring the engine is in a safe condition for manual rotation. Use the appropriate tools to engage the shaft with the flywheel or crankshaft slot. Rotate the engine slowly to confirm smooth operation. Safety precautions should include disconnecting the battery and ensuring all personnel are clear of moving parts 3.

Troubleshooting Common Issues

Common problems with barring shafts may include difficulty in rotation or unusual noises during operation. These issues can often be traced to obstructions within the engine or misalignment of components. Troubleshooting steps involve inspecting the engine for debris, ensuring all components are properly aligned, and checking for any signs of damage or wear on the shaft itself 1.

Maintenance Tips

Regular maintenance of the Cummins 3681701 Barring Shaft is important for optimal performance and longevity. This includes periodic lubrication to reduce friction and wear, as well as routine inspections for signs of damage or excessive wear. Replacement guidelines should be followed if the shaft shows significant signs of wear or if it no longer rotates the engine smoothly 2.

Cummins Corporation

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration systems, and related technologies. With a history of innovation and quality, Cummins has established a strong reputation in the automotive and heavy-duty truck industry. The company’s product range is designed to meet the demanding requirements of various applications, ensuring reliability and performance 3.

Barring Shaft (Part 3681701) in Cummins Engines

The Barring Shaft, identified by part number 3681701, is a critical component in the Cummins QSX15 CM2250, QSX15 CM2250 ECF, and QSX15 CM2350 X105 engines. This part plays a pivotal role in the engine’s operation by ensuring that the crankshaft rotates at a consistent speed, which is essential for the engine’s smooth and efficient functioning.

In the QSX15 CM2250 and QSX15 CM2250 ECF engines, the Barring Shaft is designed to counteract any fluctuations in the crankshaft’s rotational speed. This is particularly important in maintaining the engine’s performance under varying loads and conditions. The Barring Shaft achieves this by using a system of gears and springs that work together to stabilize the crankshaft’s rotation.

For the QSX15 CM2350 X105 engine, the Barring Shaft’s role is similarly crucial. This engine variant, while sharing many components with the QSX15 CM2250 series, may have specific design nuances that require the Barring Shaft to perform its function with even greater precision. The Barring Shaft in this engine ensures that the crankshaft maintains a steady speed, which is vital for the engine’s overall reliability and longevity.

Overall, the Barring Shaft is an integral part of the engine’s design, ensuring that the crankshaft operates smoothly and efficiently across all engine variants. Its importance cannot be overstated, as it directly impacts the engine’s performance and durability 1.

Role of Part 3681701 Barring Shaft in Engine Systems

The 3681701 Barring Shaft is an essential component in the operation of various engine systems, particularly in the context of engine barring procedures. Its primary function is to facilitate the smooth rotation of the engine’s crankshaft during maintenance or when the engine is not under power. This rotation is vital for several reasons:

-

Drive Mechanism: The Barring Shaft is integrated into the drive mechanism of the engine. It ensures that the crankshaft can be turned without the application of the engine’s power. This is particularly important during engine assembly, disassembly, or when performing maintenance tasks that require the engine components to be moved manually.

-

Engine Barring: In the process of engine barring, the Barring Shaft plays a significant role. It allows for the manual rotation of the crankshaft, which is necessary to check for any obstructions, ensure proper alignment of engine components, and verify that there are no binding issues within the engine.

-

Engine Barring Device: When used with an engine barring device, the Barring Shaft enables technicians to rotate the crankshaft at a controlled speed. This is important for inspecting the engine’s internal components, such as pistons, connecting rods, and valve trains, without the risk of damage that could occur if the engine were started under such conditions.

-

Engine Barring Housing: The Barring Shaft is often housed within a specially designed engine barring housing. This housing provides a secure and stable environment for the Barring Shaft to operate. It also protects the shaft from external contaminants and ensures that the rotation is smooth and consistent.

In summary, the 3681701 Barring Shaft is a key component in facilitating the safe and effective rotation of the crankshaft in various engine systems. Its integration with the drive mechanism, engine barring processes, barring devices, and housing ensures that maintenance and inspection procedures can be carried out efficiently and with minimal risk to the engine’s internal components 2.

Conclusion

The Cummins 3681701 Barring Shaft is a vital component in the maintenance and operation of heavy-duty truck engines. Its role in facilitating smooth crankshaft rotation during startup and maintenance procedures ensures proper alignment, lubrication, and reduced wear on engine components. The shaft’s design, featuring high-strength materials and precise machining, contributes to its reliability and longevity. Regular maintenance and proper installation are crucial for optimal performance. Cummins Inc.’s reputation for quality and innovation underscores the importance of this part in ensuring engine reliability and efficiency 3.

-

Owen C Duffy and Gus Wright, Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems (Jones Bartlett Learning, 2016)

↩ ↩ ↩ ↩ -

Steve Rendle, Martynn Randall, Haynes Diesel Engine Systems and Data Book (Haynes Publishing, 2000)

↩ ↩ ↩ ↩ -

Qianfan Xin, Diesel Engine System Design (Woodhead Publishing Limited, 2011)

↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.