This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3522880 Shaft Wheel Rotor is a component designed for use in the braking systems of commercial trucks. It serves a significant role in ensuring the effective operation of the braking mechanism, which is vital for the safe and efficient performance of trucks in various operational environments.

Basic Concepts of Shaft Wheel Rotors

A shaft wheel rotor is a component within a vehicle’s braking system. It functions by providing a surface for the brake pads to make contact with, thereby facilitating the deceleration or stopping of the vehicle. The rotor is attached to the wheel hub and rotates with the wheel. Its components typically include the rotor disc, which is the friction surface, and the rotor shaft, which connects the rotor to the wheel hub 1.

Role of the 3522880 Shaft Wheel Rotor in Truck Operation

The 3522880 Shaft Wheel Rotor plays a role in the braking system of a truck by providing a friction surface for the brake pads. When the brake pedal is pressed, hydraulic pressure is applied to the brake pads, forcing them against the rotor. This creates friction, which slows down the rotation of the wheels, thereby decelerating the truck. The rotor’s design and material are engineered to withstand high temperatures and repeated stress, ensuring consistent braking performance 2.

Key Features of the 3522880 Shaft Wheel Rotor

The 3522880 Shaft Wheel Rotor is characterized by its robust design and the use of high-quality materials. It is engineered to provide enhanced performance and durability. The rotor is designed to dissipate heat efficiently, which helps in maintaining optimal braking performance under various conditions. Additionally, its precise manufacturing ensures a smooth surface for consistent brake pad contact 3.

Benefits of Using the 3522880 Shaft Wheel Rotor

The use of the 3522880 Shaft Wheel Rotor offers several benefits. It contributes to improved braking performance by providing a reliable friction surface for the brake pads. Its durable construction ensures longevity, reducing the frequency of replacements. Furthermore, the efficient heat dissipation capability of the rotor helps in preventing brake fade, which is the reduction in braking efficiency that can occur under prolonged or heavy use 4.

Installation and Compatibility

Proper installation of the 3522880 Shaft Wheel Rotor is important for ensuring its effective operation. It should be installed according to the manufacturer’s guidelines to ensure it is securely attached to the wheel hub and properly aligned. Compatibility with various truck models and braking systems should be verified to ensure optimal performance and safety 5.

Maintenance and Troubleshooting

Regular maintenance of the 3522880 Shaft Wheel Rotor is important for its longevity and performance. This includes periodic inspections for signs of wear, damage, or warping. Common issues may include uneven wear or the development of hot spots, which can affect braking performance. Troubleshooting tips may involve checking the alignment and condition of the rotor, as well as ensuring that the brake pads are in good condition and properly seated 6.

Performance and Efficiency

The 3522880 Shaft Wheel Rotor contributes to the overall performance and efficiency of the truck’s braking system. Its design and material properties are engineered to provide consistent braking performance under a variety of conditions. Efficient heat dissipation and durable construction help in maintaining optimal braking efficiency, which is important for the safe operation of the truck 7.

Safety Considerations

Safety is a paramount consideration when using the 3522880 Shaft Wheel Rotor. Proper installation, regular maintenance, and adherence to the manufacturer’s guidelines are important for ensuring safe operation. Potential hazards may include reduced braking efficiency due to wear or damage to the rotor, which can compromise the safety of the vehicle and its occupants 8.

Cummins: A Brief Overview

Cummins Inc. is a well-established company in the commercial truck industry, known for its range of high-quality diesel engines and components. The company has a long history of innovation and excellence, providing reliable and efficient solutions for the transportation sector. Its product range includes engines, filtration systems, and aftermarket parts, all designed to meet the demanding requirements of commercial trucking 9.

Shaft Wheel Rotor Part 3522880 Compatibility with Cummins Engines

The Shaft Wheel Rotor part 3522880 is a critical component in the operation of several Cummins engines, ensuring precise timing and synchronization of various engine functions. This part is designed to fit seamlessly into the following Cummins engine models:

- 6C8.3

- M11 CELECT PLUS

- QSB6.7 M CM2250

These engines, while differing in their specific applications and configurations, share a commonality in their requirement for a reliable Shaft Wheel Rotor. This part plays a pivotal role in the engine’s operation, particularly in the management of fuel injection timing and the synchronization of the engine’s internal components 10.

Understanding the Role of Part 3522880 Shaft Wheel Rotor in Engine Systems

Part 3522880 Shaft Wheel Rotor is an integral component in various engine systems, particularly those involving turbochargers and aftermarket performance enhancements. Its role is to facilitate the efficient transfer of rotational energy within the turbocharger assembly, ensuring optimal performance and reliability.

Integration with Turbocharger Components

-

Turbocharger Core and Housing Kit: The Shaft Wheel Rotor is a key element in the turbocharger core and housing kit. It connects the turbine wheel to the compressor wheel, allowing the energy from the exhaust gases to spin the turbine, which in turn drives the compressor.

-

Core Assembly: Within the core assembly, the Shaft Wheel Rotor ensures seamless operation between the turbine and compressor. This assembly is responsible for the overall efficiency of the turbocharger, and the rotor plays a significant role in maintaining the balance and precision required for high-performance applications.

-

Core Assembly - H1E and H1E Rotor Assembly: Specifically designed for high-efficiency applications, the H1E core assembly relies on the Shaft Wheel Rotor to maintain the integrity of the rotating components. The H1E rotor assembly is engineered for enhanced performance, and the rotor ensures that the turbine and compressor wheels operate in unison.

-

Core Assembly Heat Exchanger40: In systems incorporating a heat exchanger, the Shaft Wheel Rotor helps in managing the thermal loads by ensuring smooth operation of the turbocharger. This is particularly important in high-stress environments where thermal management is crucial for longevity and performance.

Performance Parts and Rotor Assembly

-

Performance Parts: When integrating performance parts into an engine system, the Shaft Wheel Rotor is often upgraded to handle increased rotational speeds and loads. This ensures that the turbocharger can meet the demands of enhanced engine performance without compromising reliability.

-

Rotor Assembly: The rotor assembly, which includes the Shaft Wheel Rotor, is designed to withstand the rigors of high-speed rotation. It is a fundamental component in ensuring that the turbocharger operates efficiently across a wide range of engine speeds and loads.

Turbocharger Kits

-

Turbocharger Kit: A comprehensive turbocharger kit includes the Shaft Wheel Rotor as a vital component. It ensures that the turbocharger is capable of delivering the promised performance improvements by maintaining the necessary rotational integrity.

-

Turbocharger Kit H1E Auto and H1E Indicator: These specialized kits are designed for automated and indicator-based turbocharger systems. The Shaft Wheel Rotor in these kits is precision-engineered to work with the specific requirements of these advanced systems, ensuring accurate and reliable performance.

Turbocharger Core and Turbocharger Rotor

-

Turbocharger Core: The core of any turbocharger system relies on the Shaft Wheel Rotor to connect and balance the turbine and compressor wheels. This balance is essential for the efficient transfer of energy and the overall performance of the turbocharger.

-

Turbocharger Rotor: The turbocharger rotor, which includes the Shaft Wheel Rotor, is responsible for the smooth and efficient operation of the turbocharger. It ensures that the energy from the exhaust gases is effectively converted into increased air flow to the engine, enhancing performance and efficiency.

Conclusion

In summary, the 3522880 Shaft Wheel Rotor is a fundamental component in various engine systems, particularly those involving turbochargers. Its role in connecting and balancing the turbine and compressor wheels ensures efficient energy transfer and optimal performance across a range of applications.

-

Lakshminarayanan, P. A., & Kumar, A. (2020). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature.

↩ -

Aird, F. (2001). Bosch Fuel Injection Systems. HP Books.

↩ -

Randall, M. (2015). Haynes Manual on Diesel Engines. Haynes Publishing.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for B6.7N CM2380 B150B. Bulletin Number 5467666.

↩ -

Lakshminarayanan, P. A., & Kumar, A. (2020). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature.

↩ -

Randall, M. (2015). Haynes Manual on Diesel Engines. Haynes Publishing.

↩ -

Aird, F. (2001). Bosch Fuel Injection Systems. HP Books.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for B6.7N CM2380 B150B. Bulletin Number 5467666.

↩ -

Cummins Inc. (n.d.). Company Overview. Retrieved from Cummins Official Website.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for B6.7N CM2380 B150B. Bulletin Number 5467666.

↩

SPECIFICATIONS

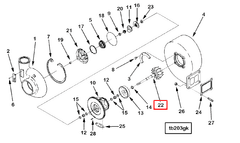

BILL OF MATERIALS

| Name | Quantity | Part Number |

|---|---|---|

| Oil Baffle | 1 | 3503668 |

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.