This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

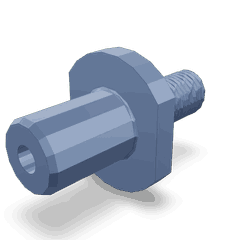

The Cummins 3325495 Pivot Shaft is a component designed for use in commercial trucks. It serves a specific function within the truck’s mechanical system, contributing to the overall operation and efficiency of the vehicle. Understanding its purpose and significance is key to maintaining and optimizing truck performance.

Basic Concepts of Pivot Shafts

A pivot shaft is a mechanical component that allows for rotational movement around a fixed point. In the context of commercial trucks, pivot shafts are utilized in various systems to enable the smooth operation of moving parts. They play a role in facilitating the motion required for functions such as steering, suspension, and other mechanical operations 1.

Purpose of the Cummins 3325495 Pivot Shaft

This Cummins part is integral to the mechanical system of a truck. It allows for the necessary rotational movement in specific components, ensuring that parts can move as designed without undue friction or wear. This component contributes to the efficient operation of the truck by supporting the movement and alignment of other parts within the system.

Key Features

The Cummins 3325495 Pivot Shaft is characterized by several key features that enhance its performance and durability. It is constructed from high-quality materials, ensuring resistance to wear and corrosion. The design incorporates precision engineering to facilitate smooth operation and reduce the likelihood of mechanical failure. Unique characteristics, such as specific coatings or treatments, may be applied to further enhance its performance under demanding conditions.

Benefits

The use of the Cummins 3325495 Pivot Shaft offers several benefits. It contributes to improved truck performance by ensuring that moving parts operate efficiently. Its durable construction enhances the reliability of the truck’s mechanical system, reducing the need for frequent replacements or repairs. Additionally, the pivot shaft’s design helps in maintaining alignment and reducing wear on associated components, leading to a longer service life for the truck.

Installation Process

Installing the Cummins 3325495 Pivot Shaft requires careful attention to detail. The process involves securing the shaft in its designated position within the truck’s mechanical system, ensuring it is properly aligned and fastened. Tools and equipment specific to this task may be required, and safety precautions should be observed to protect against injury or damage to the component.

Maintenance and Care

Regular maintenance and care of the Cummins 3325495 Pivot Shaft are vital for ensuring optimal performance and longevity. This includes periodic inspection for signs of wear or damage, cleaning to remove dirt and debris, and lubrication to reduce friction. Adhering to a maintenance schedule helps in identifying potential issues before they lead to mechanical failure.

Troubleshooting Common Issues

Common issues with the Cummins 3325495 Pivot Shaft may include wear, misalignment, or damage due to excessive force or corrosion. Troubleshooting steps involve inspecting the shaft for visible signs of damage, checking alignment with other components, and assessing the condition of any associated parts. Solutions may range from realigning or lubricating the shaft to replacing damaged components.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. Its product range includes a variety of components and systems designed to enhance the performance, efficiency, and reliability of commercial vehicles 2.

Pivot Shaft 3325495 in Cummins Engines

The Pivot Shaft 3325495, manufactured by Cummins, is a critical component in several of their engine models. This part is integral to the operational integrity and efficiency of the engines it fits.

K19 and NH/NT 855 Engines

The Pivot Shaft 3325495 is designed to fit seamlessly within the K19 and NH/NT 855 engines. Its role in these engines is to facilitate smooth rotational movements, ensuring that the engine’s internal components operate without undue friction or wear. This shaft’s precision engineering is crucial for maintaining the balance and performance of these engines.

QSK19 CM850 MCRS and QSNT14 CM876 N102 Engines

In the QSK19 CM850 MCRS and QSNT14 CM876 N102 engines, the Pivot Shaft 3325495 serves a similar function. It is engineered to endure the high-stress environments within these engines, providing a stable pivot point that is essential for the proper functioning of various engine parts. The durability and precision of this shaft contribute to the overall reliability and longevity of these engines.

The Pivot Shaft 3325495 is a testament to Cummins’ commitment to quality and performance, ensuring that it meets the rigorous demands of its various engine applications.

Role of Part 3325495 Pivot Shaft in Engine Systems

This part is integral to the efficient operation of several components within engine systems. It facilitates the smooth rotation and alignment necessary for optimal performance.

Drive Mechanism

In the drive mechanism, the pivot shaft ensures that power transmission from the engine to the driven components is consistent and reliable. Its role is to maintain the correct angular relationship between the drive components, allowing for efficient power transfer without undue stress on the system.

Fan System

Within the fan system, the pivot shaft is responsible for the precise movement of the fan. It allows the fan to pivot as needed to maintain airflow, which is essential for cooling the engine and other components. The pivot shaft’s design enables the fan to adjust its angle in response to varying operational demands, ensuring consistent cooling performance.

Fan Arrangement

The pivot shaft plays a significant role in the overall fan arrangement by providing the necessary pivot points for the fan blades. This arrangement allows for dynamic adjustments to the fan’s position, optimizing airflow direction and volume. The pivot shaft ensures that the fan can respond to changes in engine load and environmental conditions, maintaining effective cooling.

Fan Hub

Connected to the fan hub, the pivot shaft allows for rotational movement that is vital for the fan’s operation. The hub, which houses the fan blades, relies on the pivot shaft to distribute the rotational force evenly. This even distribution is key to preventing imbalances that could lead to vibrations or reduced efficiency.

Fan Idler

In systems that incorporate a fan idler, the pivot shaft enables the idler to move as required. The idler, which helps in tensioning the fan belt, relies on the pivot shaft to adjust its position. This adjustment is necessary to maintain the correct tension on the belt, ensuring smooth and efficient fan operation.

Idler Lever

The pivot shaft also interacts with the idler lever, allowing it to pivot and adjust the tension on the fan belt. This interaction is essential for the longevity and performance of the belt, as it prevents slippage and ensures consistent power transmission from the engine to the fan.

Overall, the part 3325495 pivot shaft is a key component in maintaining the operational integrity of these engine systems, ensuring that each part functions harmoniously within the assembly.

Conclusion

The Cummins 3325495 Pivot Shaft is a critical component in the mechanical systems of commercial trucks and engines. Its role in facilitating smooth rotational movements and ensuring the efficient operation of various engine parts underscores its importance in maintaining vehicle performance and reliability. Regular maintenance and proper installation are essential to maximize the benefits of this component.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.