This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3176835 Idler Shaft is a component designed for use in heavy-duty trucks. It serves a specific function within the truck’s drivetrain, contributing to the efficient transfer of power and the overall performance of the vehicle. Understanding its purpose and significance is fundamental for maintaining and optimizing truck operations.

Basic Concepts of Idler Shafts

An idler shaft is a mechanical component that supports and guides belts, chains, or other moving parts within a system. Its general function is to maintain tension, alignment, and smooth operation of these parts. In the context of a truck’s drivetrain, the idler shaft ensures that power is transmitted effectively from the engine to the wheels, playing a role in the vehicle’s propulsion system 1.

Role of the 3176835 Idler Shaft in Truck Operation

This Cummins part is integral to the operation of a truck by facilitating the proper functioning of the drivetrain. It interacts with other components such as gears, belts, and pulleys, ensuring that power is distributed efficiently. This shaft contributes to the truck’s performance by maintaining the alignment and tension of the drivetrain components, which is vital for smooth and reliable operation 2.

Key Features of the 3176835 Idler Shaft

The design and construction of the 3176835 Idler Shaft incorporate several features that enhance its functionality and durability. These include the use of high-quality materials for resistance to wear and corrosion, precision machining for accurate fit and performance, and the integration of robust bearings to support smooth rotation and reduce friction. These features collectively contribute to the shaft’s reliability and longevity in demanding truck applications 3.

Benefits of Using the 3176835 Idler Shaft

Utilizing this part in a truck’s drivetrain offers several advantages. It contributes to improved efficiency by ensuring that power is transmitted with minimal loss. Additionally, it reduces wear on other components by maintaining proper alignment and tension, leading to enhanced reliability and potentially extending the lifespan of the drivetrain system 4.

Installation Considerations

When installing the 3176835 Idler Shaft, it is important to follow guidelines and best practices to ensure proper function and longevity. This includes using the necessary tools for precise installation, adhering to alignment procedures to maintain the integrity of the drivetrain, and applying the correct torque specifications to secure the shaft in place without overtightening, which could lead to damage.

Troubleshooting Common Issues

Common problems associated with idler shafts, such as noise, vibration, and premature wear, can often be traced back to installation errors, lack of maintenance, or inherent design limitations. Diagnostic steps may involve inspecting the shaft and its bearings for signs of wear or damage, checking alignment and tension within the drivetrain, and addressing any issues promptly to prevent further complications.

Maintenance Recommendations

Routine maintenance of the 3176835 Idler Shaft is key to ensuring its longevity and optimal performance. This includes regular inspection intervals to check for signs of wear or damage, adhering to lubrication requirements to reduce friction and wear, and following replacement guidelines when the shaft shows signs of significant wear or failure. Proper maintenance practices help maintain the efficiency and reliability of the truck’s drivetrain.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and power generation products. With a strong reputation in the automotive and heavy-duty truck industries, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and technological advancements contribute to its standing as a trusted provider of power solutions.

Idler Shaft Part 3176835 in Cummins Engines

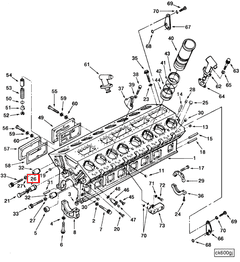

The Idler Shaft part 3176835, manufactured by Cummins, is a critical component in the engine systems of the K38 and K50 engines. This part plays a pivotal role in the proper functioning of the engine by maintaining the tension of the timing belt or chain, ensuring that the engine’s valves and pistons operate in harmony.

In the K38 engine, the Idler Shaft 3176835 is designed to work seamlessly with the engine’s architecture, providing the necessary support to keep the timing belt or chain taut. This helps in reducing wear and tear on the belt or chain, thereby extending its lifespan and ensuring smooth engine operation.

Similarly, in the K50 engine, the Idler Shaft 3176835 is engineered to fit precisely within the engine’s design parameters. Its role is to stabilize the timing mechanism, which is crucial for the engine’s performance and longevity. The design of this part ensures that it can handle the specific stresses and conditions encountered in the K50 engine.

Both engines benefit from the use of the Idler Shaft 3176835, as it contributes to the overall reliability and efficiency of the engine. This part is a testament to Cummins’ commitment to providing high-quality components that enhance engine performance and durability.

Role of Part 3176835 Idler Shaft in Engine Systems

The idler shaft, designated as part 3176835, is an integral component in the timing system of an engine. It is responsible for maintaining the proper alignment and tension of the timing chain or belt, which is essential for the synchronization of the camshaft and crankshaft.

In the context of a Base Part or Base Parts, the idler shaft ensures that the timing mechanism operates smoothly, reducing the likelihood of timing chain slack or excessive tension that could lead to engine misfires or damage.

When integrated into a Block Cylinder Kit or Cylinder Block, the idler shaft plays a supportive role by facilitating the precise movement of the timing components. This is particularly important in high-performance engines where timing accuracy can significantly affect engine efficiency and power output.

In a Cylinder Block Kit or Cylinder Short Block, the idler shaft contributes to the overall reliability of the engine by ensuring that the valve timing remains consistent throughout the engine’s operation. This consistency is vital for the engine’s durability and performance.

For assemblies such as the Long Block Assy. - 50, the idler shaft is a key element that helps in the seamless integration of the timing system with other engine components. Its proper function is essential for the long-term reliability of the engine, especially in demanding applications.

In Hardware Kits and Service Block Kits, the idler shaft is often included to ensure that the timing system is correctly set up during engine rebuilds or maintenance procedures. Its role in these kits underscores the importance of precise timing for the engine’s optimal performance.

Overall, the idler shaft (part 3176835) is a fundamental component that supports the efficient and reliable operation of the engine’s timing system across various engine configurations and kits.

Conclusion

The Cummins 3176835 Idler Shaft is a vital component in the drivetrain of heavy-duty trucks, ensuring efficient power transfer and optimal vehicle performance. Its design features, such as high-quality materials and precision machining, contribute to its durability and reliability. Proper installation, maintenance, and troubleshooting are essential for maximizing the lifespan and efficiency of this part. Cummins’ commitment to quality is evident in the design and functionality of the 3176835 Idler Shaft, making it a critical element in the performance and longevity of truck engines.

-

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE Books, 2023.

↩ -

Miedema, S. A., and Z. Lu. The Dynamic Behavior of a Diesel Engine. Published by Drir S. A. Miedema, 2010.

↩ -

Rajamani, Rajesh. Vehicle Dynamics and Control. Springer, 2005.

↩ -

Lakshminarayanan, P A, and Yogesh V Aghav. Modelling Diesel Combustion. Springer Science, 2010.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.