The Cummins 5261237 Pressure Sensor is a component designed to monitor and regulate pressure within the systems of commercial trucks. Its purpose is to provide accurate pressure readings that contribute to the efficient and safe operation of the vehicle. This sensor plays a role in maintaining the performance and reliability of truck systems by ensuring that pressure levels remain within optimal ranges.

Basic Concepts of Pressure Sensors

Pressure sensors are devices that measure the force exerted by a fluid (liquid or gas) on a surface. They convert this physical pressure into an electrical signal, which can then be interpreted by the vehicle’s electronic control systems. In automotive applications, pressure sensors are used to monitor various systems such as the engine, transmission, and braking systems. They provide data that helps in the regulation and optimization of these systems, ensuring they operate efficiently and safely 1.

Role of the 5261237 Pressure Sensor in Truck Operation

The Cummins 5261237 Pressure Sensor is integrated into the truck’s systems to monitor specific pressure points. It provides real-time data to the truck’s electronic control unit (ECU), which uses this information to make adjustments to the engine and other systems as needed. This sensor helps in maintaining the correct pressure levels, which is vital for the efficient combustion of fuel, the proper functioning of the turbocharger, and the overall performance of the engine. By delivering precise pressure readings, it contributes to the smooth operation and longevity of the truck’s components 2.

Key Features

The Cummins 5261237 Pressure Sensor is designed with several features that enhance its performance and reliability. It is constructed using durable materials that can withstand the harsh conditions found in commercial truck environments. The sensor is equipped with advanced technology that ensures accurate and consistent pressure readings. Its design allows for easy integration into the truck’s systems, and it is built to meet the high standards set by Cummins Inc. for quality and performance.

Benefits of Using the 5261237 Pressure Sensor

Utilizing the Cummins 5261237 Pressure Sensor offers several advantages. It contributes to improved engine performance by ensuring that pressure levels are maintained within the optimal range. This leads to more efficient fuel combustion and reduced emissions. Additionally, the sensor enhances safety by providing the ECU with the data needed to make timely adjustments, preventing potential issues that could arise from incorrect pressure levels. Furthermore, it increases the efficiency of truck operations by helping to maintain the vehicle in top condition, reducing the likelihood of unexpected downtime 3.

Installation and Integration

Proper installation of the Cummins 5261237 Pressure Sensor is important for its effective operation. It should be installed according to the manufacturer’s guidelines to ensure it is correctly positioned and securely attached. Integration into the truck’s system requires careful attention to ensure that all connections are made properly and that the sensor is compatible with the truck’s ECU. Any necessary preparations, such as cleaning the installation area or checking for compatibility with existing systems, should be completed before installation.

Troubleshooting and Maintenance

To ensure the longevity and optimal performance of the Cummins 5261237 Pressure Sensor, regular maintenance and troubleshooting are recommended. Common issues may include inaccurate readings or sensor failure, which can often be traced back to poor installation, environmental factors, or wear and tear. Maintenance tips include checking the sensor for signs of damage, ensuring all connections are secure, and keeping the sensor clean. If the sensor shows signs of potential failure, such as inconsistent readings or error messages from the ECU, it may need to be replaced or repaired.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing high-quality, reliable components. The company’s product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of commercial vehicles. Cummins is known for its commitment to innovation, quality, and customer satisfaction, making it a trusted name in the industry.

Cummins Pressure Sensor 5261237 Compatibility

The Cummins Pressure Sensor part number 5261237 is designed to fit a variety of Cummins engines. This sensor plays a role in monitoring and regulating engine pressure, ensuring optimal performance and efficiency. Below is a detailed breakdown of the engines with which this pressure sensor is compatible:

B Series Engines

- B4.5 CM2350 B129B

- B6.7 CM2350 B135B

- B6.7 CM2670 B153B

F Series Engines

- F3.8 CM2350 F120B

- F3.8 CM2350 F128C

- F3.8 CM2620 F137B

ISB Series Engines

- ISB (Chrysler)

- ISB CM2150

- ISB CM850

- ISB/ISD4.5 CM2150 B119

- ISB/ISD6.7 CM2150 SN

- ISB4.5 CM2350 B104

- ISB6.7 CM2250

- ISB6.7 CM2350 B101

ISBE Series Engines

- ISBE CM2150

- ISBE4 CM850

ISF Series Engines

- ISF3.8 CM2350 F109

QSB Series Engines

- QSB4.5 CM2250 EC

- QSB6.7 CM2250

- QSB6.7 M CM2250

QSF Series Engines

- QSF3.8 CM2350 F107

This pressure sensor is engineered to integrate seamlessly with these engines, providing reliable pressure readings that are important for maintaining engine health and performance.

Role of Part 5261237 Pressure Sensor in Engine Systems

The part 5261237 Pressure Sensor is integral to the efficient operation of various engine systems. It is strategically positioned to monitor and report pressure changes within the engine, ensuring optimal performance and reliability.

Interaction with the Camshaft

The camshaft operates in synchronization with the crankshaft to open and close the engine’s valves at precise moments. The pressure sensor provides real-time data on the pressure within the cylinder, allowing the Engine Control Module (ECM) to make necessary adjustments to the camshaft timing. This ensures that the valves open and close at the most efficient points in the engine cycle, enhancing overall engine performance.

Coordination with the Connecting Rod and Piston

As the connecting rod transfers the piston’s linear motion to the crankshaft’s rotational motion, the pressure sensor monitors the pressure within the cylinder. This data is vital for the ECM to adjust the fuel injection timing and quantity, ensuring that the combustion process is optimized. Proper pressure management helps in maintaining the structural integrity of the connecting rod and piston, reducing wear and tear.

Integration with the Cylinder Head

The cylinder head houses the valves and fuel injectors and is a critical component in the combustion process. The pressure sensor’s readings help the ECM fine-tune the air-fuel mixture and ignition timing. This ensures that the combustion process is efficient, reducing the risk of knocking and other performance issues. Accurate pressure data also aids in the management of valve timing, contributing to the longevity of the cylinder head.

Communication with the Engine Control Module (ECM)

The ECM relies on the pressure sensor to gather precise pressure data from various points within the engine. This information is used to make real-time adjustments to fuel delivery, ignition timing, and valve operation. The pressure sensor’s role in providing this data is important for the ECM to maintain optimal engine performance under varying conditions.

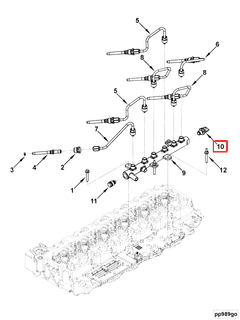

Functionality in the Fuel Manifold

In the fuel manifold, the pressure sensor monitors the pressure of the fuel as it is distributed to the injectors. This ensures that the fuel is delivered at the correct pressure, allowing for efficient atomization and combustion. Proper fuel pressure management is key to achieving the desired power output and fuel efficiency.

Support for the Injector

The injector’s role is to deliver fuel into the combustion chamber at the right time and in the right amount. The pressure sensor provides feedback on the pressure within the fuel system, enabling the ECM to adjust the injector’s operation. This ensures that the fuel is delivered precisely when needed, optimizing combustion efficiency and reducing emissions.

Role in Injector Plumbing

The injector plumbing system must maintain consistent fuel pressure to ensure reliable injector operation. The pressure sensor monitors this pressure, allowing the ECM to make adjustments as needed. This helps prevent issues such as fuel starvation or over-pressurization, which can lead to poor engine performance and potential damage.

Contribution to the Long Block

The long block, comprising the engine block, crankshaft, pistons, and other core components, relies on precise pressure management for optimal operation. The pressure sensor’s data helps the ECM make adjustments that ensure the long block operates within safe pressure limits, enhancing durability and performance.

Enhancement of Performance Parts

Performance parts, such as high-flow fuel injectors or upgraded camshafts, require precise pressure management to function effectively. The pressure sensor provides the necessary data for the ECM to make real-time adjustments, ensuring that these performance parts operate at their peak efficiency. This contributes to improved engine performance and reliability.

Conclusion

The Cummins 5261237 Pressure Sensor is a vital component in the operation of commercial trucks, ensuring that pressure levels within the engine and other systems are maintained at optimal levels. Its accurate readings contribute to efficient fuel combustion, reduced emissions, and enhanced safety. Proper installation, regular maintenance, and troubleshooting are essential to ensure the sensor’s longevity and performance. Cummins Inc.’s reputation for quality and innovation underscores the reliability and effectiveness of this part in commercial truck applications.

-

Sully, F. K. (1998). Motor Vehicle Mechanics Textbook, Fifth Edition. Heinemann Professional Publishing.

↩ -

Duffy, O. C., & Wright, G. (2016). Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems. Jones Bartlett Learning.

↩ -

Klyde, M., & VanGelder, K. (2010). Advanced Automotive Electricity and Electronics. Jones Bartlett Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.