This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

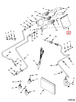

The 4364651 Sensor Bracket, manufactured by Cummins, is a component specifically designed for use in commercial trucks. This part plays a role in supporting the placement and function of various sensors within the truck’s engine system. Cummins, a well-established manufacturer in the commercial truck industry, produces this bracket to ensure reliable and efficient operation of trucks 1.

Purpose and Functionality

The Sensor Bracket serves to securely hold sensors in place within the engine compartment of a truck. By providing a stable mounting point, it allows sensors to accurately monitor various engine parameters such as temperature, pressure, and emissions. This accurate monitoring is vital for the engine control unit (ECU) to make precise adjustments to the engine’s operation, thereby enhancing performance and efficiency 2.

Key Features

This Cummins part is constructed from durable materials that can withstand the harsh conditions of a commercial truck environment. Its design includes features that facilitate easy sensor attachment and detachment, which simplifies maintenance and replacement processes. Additionally, the bracket is engineered to resist corrosion and mechanical stress, ensuring long-term reliability 3.

Benefits

Using the 4364651 offers several advantages. It provides improved stability for sensors, which is crucial for accurate data collection. The ease of installation reduces downtime during maintenance, and its robust construction contributes to the overall durability and performance of the truck. Furthermore, the bracket’s design helps in protecting sensors from physical damage and environmental factors, which can otherwise lead to sensor malfunction 4.

Installation Process

Installing the 4364651 involves several steps to ensure it is correctly positioned and securely attached. First, the area where the bracket will be mounted should be cleaned and inspected for any damage. The bracket is then aligned with the mounting points and fastened using the provided hardware. It is important to ensure that the bracket is level and that all fasteners are tightened to the specified torque settings to prevent any movement or loosening over time.

Maintenance and Troubleshooting

Regular maintenance of the 4364651 includes inspecting it for signs of wear, corrosion, or damage. Any issues should be addressed promptly to prevent sensor malfunction. Common problems may include loose fasteners or bracket deformation, which can be resolved by re-tightening or replacing the bracket as necessary. Ensuring that the bracket remains in good condition is key to maintaining the accuracy and reliability of the sensors it supports.

Compatibility and Applications

The 4364651 is designed for use in specific models of commercial trucks and engines. Its application is tailored to fit within the engine compartments of these vehicles, ensuring compatibility with the sensor types and configurations used. This bracket is an integral part of the engine monitoring system, applicable across various commercial truck models to enhance operational efficiency.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation for quality and innovation in the commercial truck industry. The company’s product range includes a variety of components and systems designed to improve the performance, efficiency, and reliability of commercial vehicles.

Cummins Sensor Bracket 4364651 Compatibility

The Cummins Sensor Bracket part number 4364651 is designed to be compatible with a range of Cummins engines, ensuring a secure and precise mounting for various sensors. This bracket is engineered to fit seamlessly within the engine architecture of the following Cummins engines:

- QSK60

- CM850

- MCRS

These engines, while differing in their specific applications and power outputs, share common design elements that allow the 4364651 sensor bracket to be universally applicable. The bracket’s design ensures it can be integrated into the engine’s framework without requiring modifications, facilitating ease of installation and maintenance.

For the QSK60 and CM850 engines, the sensor bracket is particularly crucial in maintaining the integrity of sensor positioning, which is vital for optimal engine performance and diagnostics. The MCRS engine, known for its reliability in marine applications, also benefits from the precise fit and secure hold provided by the 4364651 bracket, ensuring that sensors remain accurately positioned under varying operational conditions.

The compatibility of the 4364651 sensor bracket across these engines underscores Cummins’ commitment to providing high-quality, versatile components that enhance engine functionality and reliability.

Role of Part 4364651 Sensor Bracket in Engine Systems

The Sensor Bracket, identified by part number 4364651, is an integral component in the assembly and functionality of engine monitoring systems. This bracket serves as a mounting point for various sensors that are essential for the accurate monitoring and regulation of engine performance.

In the context of an engine monitoring system, the Sensor Bracket securely holds sensors in place, ensuring they are correctly positioned to gather precise data. This data includes metrics such as temperature, pressure, and other vital signs of engine health. The bracket’s design allows for easy installation and removal, facilitating routine maintenance and sensor replacements without disrupting the overall system integrity.

Furthermore, the Sensor Bracket contributes to the structural stability of the sensor array. By providing a solid foundation, it ensures that sensors remain unaffected by engine vibrations, which could otherwise lead to inaccurate readings. This stability is particularly important in high-performance engines where even minor fluctuations can significantly impact engine efficiency and reliability.

Additionally, the bracket plays a role in the thermal management of the sensors. It is often designed to allow for adequate airflow around the sensors, preventing overheating and ensuring consistent performance over time. This is especially relevant in environments where engines operate under extreme conditions.

In summary, Part 4364651 Sensor Bracket is a key element in the engine monitoring system, ensuring sensors are accurately positioned, structurally supported, and thermally managed to provide reliable data for engine performance monitoring.

Conclusion

The 4364651 Sensor Bracket is a critical component in the engine systems of commercial trucks, offering stability, ease of maintenance, and compatibility with various Cummins engines. Its role in ensuring accurate sensor placement and data collection is vital for the optimal performance and reliability of these vehicles.

-

Rendle, S., & Randall, M. (2000). Haynes Diesel Engine Systems and Data Book. Haynes Publishing.

↩ -

Bari, S. (2013). Diesel Engine Combustion, Emissions and Condition Monitoring. InTech.

↩ -

Crolla, D. (2015). Crolla Encyclopedia. Wiley.

↩ -

Han, Z. (2022). Simulation and Optimization of Internal Combustion Engines. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.