This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

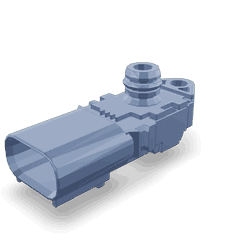

The Cummins 4359554 Pressure Sensor is a critical component designed to monitor and report pressure levels within the systems of commercial trucks. Its purpose is to provide accurate pressure readings that contribute to the efficient and safe operation of the vehicle. This sensor is significant in maintaining the optimal performance of truck systems by ensuring that pressure levels are within the required parameters.

Basic Concepts of Pressure Sensors

Pressure sensors are devices that measure the force exerted by a fluid (liquid or gas) per unit area within a system. They function by converting the physical pressure into an electrical signal, which can then be interpreted by the vehicle’s electronic control unit (ECU) 1. These sensors are widely used in automotive systems to monitor various parameters such as fuel pressure, oil pressure, and air pressure in the braking system.

Role of the 4359554 Pressure Sensor in Truck Operation

The Cummins 4359554 Pressure Sensor plays a specific role in the operation of a truck by monitoring the pressure within certain systems. It is integrated into the truck’s electronic systems to provide real-time data on pressure levels. This information is used by the ECU to make adjustments to the engine and other systems to maintain optimal performance. The sensor monitors parameters such as fuel injection pressure, which is vital for the efficient combustion process in diesel engines 2.

Key Features of the 4359554 Pressure Sensor

The Cummins 4359554 Pressure Sensor is characterized by several key features that enhance its performance. Its design incorporates high-quality materials that ensure durability and accuracy in various operating conditions. The sensor is known for its high accuracy in pressure readings, which is crucial for the precise operation of truck systems. Additionally, it may include unique technological aspects such as temperature compensation to ensure consistent performance across a range of operating temperatures 3.

Benefits of Using the 4359554 Pressure Sensor

The use of the Cummins 4359554 Pressure Sensor offers several advantages. It contributes to improved engine performance by providing accurate pressure readings that allow the ECU to optimize fuel injection. This can lead to better fuel efficiency and reduced emissions. Enhanced safety is another benefit, as the sensor helps maintain system pressures within safe limits, preventing potential failures. Increased efficiency in truck operations is also a result of the sensor’s ability to ensure that systems are operating under optimal conditions 4.

Installation and Integration

Proper installation and integration of the Cummins 4359554 Pressure Sensor into a truck’s system are important for its effective operation. Installation guidelines typically include ensuring that the sensor is correctly positioned to accurately measure the intended pressure. It may also involve connecting the sensor to the truck’s electronic system in a manner that ensures reliable data transmission. Special considerations might include protecting the sensor from environmental factors that could affect its performance 5.

Troubleshooting and Maintenance

Troubleshooting common issues related to the Cummins 4359554 Pressure Sensor may involve checking for accurate pressure readings and ensuring that the sensor is properly connected to the truck’s electronic system. Maintenance tips to ensure longevity and optimal performance include regular inspection for signs of wear or damage and cleaning the sensor as necessary to remove any contaminants that could affect its accuracy. Diagnostic procedures may be used to identify any issues with the sensor’s operation 6.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance engines and components. The company’s product range includes a variety of engines, powertrain components, and aftermarket parts designed to meet the needs of commercial vehicle operators worldwide 7.

Pressure Sensor 4359554 Compatibility with Cummins Engines

The Pressure Sensor 4359554, manufactured by Cummins, is designed to integrate seamlessly with a variety of Cummins engines. This sensor is crucial for maintaining optimal engine performance by monitoring and regulating pressure levels within the engine’s systems.

QSK60 Engine

The QSK60 engine, known for its robust performance and reliability, is compatible with the Pressure Sensor 4359554. This sensor ensures that the engine operates within safe pressure parameters, enhancing overall efficiency and longevity.

G CM2358 and K110 Engines

The G CM2358 and K110 engines also benefit from the integration of the Pressure Sensor 4359554. These engines, which are part of Cummins’ lineup, rely on precise pressure monitoring to maintain peak performance and prevent potential issues. The sensor’s compatibility with these engines ensures that they can operate smoothly and efficiently under various conditions.

Grouping of Engines

The Pressure Sensor 4359554 is engineered to fit seamlessly with the QSK60, G CM2358, and K110 engines, making it a versatile component for Cummins’ engine range. This compatibility allows for a standardized approach to engine maintenance and performance monitoring across different engine models 8.

Role of Part 4359554 Pressure Sensor in Engine Systems

The Part 4359554 Pressure Sensor is an integral component in modern engine systems, working in conjunction with the Engine Control Module (ECM) to ensure optimal engine performance and efficiency.

Integration with the Engine Control Module (ECM)

The Pressure Sensor continuously monitors the pressure levels within the engine system. It sends real-time data to the ECM, which uses this information to make precise adjustments to fuel injection, ignition timing, and other critical parameters. This dynamic feedback loop allows the ECM to maintain the engine’s performance under varying conditions, ensuring smooth operation and efficient fuel consumption 9.

Enhancing Engine Performance

By providing accurate pressure readings, the Pressure Sensor enables the ECM to fine-tune the air-fuel mixture. This results in improved combustion efficiency, reduced emissions, and enhanced overall engine performance. The sensor’s ability to detect even minor fluctuations in pressure ensures that the engine operates within its optimal range, prolonging its lifespan and reliability 10.

Supporting Diagnostic Functions

The data collected by the Pressure Sensor is also vital for diagnostic purposes. When the ECM detects anomalies in the pressure readings, it can trigger warning lights or store error codes, alerting mechanics to potential issues before they become severe. This proactive approach to maintenance helps prevent costly repairs and downtime 11.

Contribution to Fuel Efficiency

Accurate pressure monitoring by the sensor allows the ECM to optimize fuel delivery. By ensuring that the correct amount of fuel is injected at the right time, the engine achieves better fuel economy. This not only benefits the environment by reducing emissions but also saves operators money on fuel costs 12.

Role in Emission Control

Modern engines are designed to meet stringent emission standards. The Pressure Sensor plays a significant role in this by providing the ECM with the necessary data to adjust engine parameters for minimal emissions. This contributes to cleaner air and compliance with environmental regulations 13.

Conclusion

The Cummins 4359554 Pressure Sensor is a key component that enhances engine performance, supports diagnostic functions, contributes to fuel efficiency, and aids in emission control by working seamlessly with the Engine Control Module. Its accurate pressure readings and compatibility with various Cummins engines make it an essential part of modern engine systems.

-

Reif, Konrad. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ -

Denton, Tom, and Hayley Pells. Automotive Technician Training, Second Edition. Routledge, 2022.

↩ -

Crolla, David. Crolla Encyclopedia. Wiley, 2015.

↩ -

Reif, Konrad Ed. Gasoline Engine Management Systems and Components. Springer Vieweg, 2015.

↩ -

Cummins Inc. Fault Code Troubleshooting Manual. Bulletin Number 5659918.

↩ -

Cummins Inc. Fault Code Troubleshooting Manual. Bulletin Number 5659918.

↩ -

Cummins Inc. Company Overview. Retrieved from Cummins Official Website.

↩ -

Cummins Inc. Engine Compatibility Guide. Retrieved from Cummins Official Website.

↩ -

Reif, Konrad. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ -

Denton, Tom, and Hayley Pells. Automotive Technician Training, Second Edition. Routledge, 2022.

↩ -

Cummins Inc. Fault Code Troubleshooting Manual. Bulletin Number 5659918.

↩ -

Reif, Konrad Ed. Gasoline Engine Management Systems and Components. Springer Vieweg, 2015.

↩ -

Cummins Inc. Environmental Compliance Guide. Retrieved from Cummins Official Website.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.