This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4307451 Pressure Sensor is a component designed to monitor and regulate pressure levels within commercial truck systems. Its purpose is to ensure that the truck operates efficiently and safely by providing accurate pressure readings to the truck’s electronic control unit (ECU). This sensor plays a role in maintaining optimal performance and reliability in commercial truck operations 1.

Basic Concepts of Pressure Sensors

Pressure sensors are devices that measure the force exerted by a fluid (liquid or gas) on a surface. They convert this physical pressure into an electrical signal, which can then be interpreted by electronic systems. In automotive applications, pressure sensors are used in various systems, including fuel injection, brake systems, and engine management, to monitor and control pressure levels for optimal performance 2.

Role of the 4307451 Pressure Sensor in Truck Operation

The Cummins 4307451 Pressure Sensor is specifically designed to monitor pressure within the truck’s systems. It plays a role in the engine management system by providing real-time pressure data to the ECU. This data allows the ECU to make adjustments to fuel injection, turbocharging, and other critical functions, ensuring the engine operates within its optimal parameters. The sensor’s integration into the truck’s systems enhances overall performance and efficiency 3.

Key Features

The Cummins 4307451 Pressure Sensor is characterized by its robust design and high-quality materials, which ensure durability and reliability in demanding commercial truck environments. It incorporates advanced technology to provide accurate and consistent pressure readings. The sensor’s design allows for easy installation and integration into the truck’s systems, minimizing downtime and maintenance requirements.

Benefits of Using the 4307451 Pressure Sensor

Incorporating the Cummins 4307451 Pressure Sensor into truck systems offers several advantages. It contributes to improved engine efficiency by ensuring that pressure levels are maintained within optimal ranges. This leads to better fuel economy and reduced emissions. Additionally, the sensor enhances the reliability of the truck’s systems by providing accurate data for the ECU to make informed decisions. Safety is also improved, as the sensor helps prevent system failures that could lead to accidents.

Installation and Integration

Proper installation and integration of the Cummins 4307451 Pressure Sensor are crucial for its effective operation. It should be installed according to the manufacturer’s guidelines to ensure accurate readings and system compatibility. Best practices include verifying system compatibility, using the correct tools and equipment, and following a systematic approach to installation. Potential challenges may include ensuring a secure connection and protecting the sensor from environmental factors.

Troubleshooting Common Issues

Common problems associated with pressure sensors, including the Cummins 4307451, may include inaccurate readings, sensor failure, or integration issues with the truck’s systems. Troubleshooting steps may involve checking the sensor’s connection, verifying system compatibility, and ensuring the sensor is functioning within its specified parameters. Regular maintenance and inspections can help identify and resolve issues before they lead to system failures.

Maintenance Tips

Regular maintenance practices are essential to ensure the longevity and optimal performance of the Cummins 4307451 Pressure Sensor. This includes periodic inspections for signs of wear or damage, cleaning the sensor and its connections, and verifying its operation within the truck’s systems. Adhering to the manufacturer’s maintenance guidelines will help maintain the sensor’s accuracy and reliability.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. Its product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of commercial truck operations.

Pressure Sensor 4307451 Compatibility with Cummins Engines

The Pressure Sensor 4307451, manufactured by Cummins, is designed to integrate seamlessly with a variety of Cummins engine models. This sensor plays a role in maintaining optimal engine performance by accurately measuring and relaying pressure data to the engine control unit (ECU). Below is a detailed look at the compatibility of this pressure sensor with specific Cummins engine models:

QSK19 CM2350 K105 and QSK50 CM2350 K108

The Pressure Sensor 4307451 is compatible with the QSK19 CM2350 K105 and QSK50 CM2350 K108 engines. These engines are part of the Cummins QSK series, known for their robust design and high performance in heavy-duty applications. The sensor fits into the engine’s architecture by interfacing with the engine’s pressure monitoring system, ensuring precise readings that are critical for maintaining engine efficiency and longevity.

QSK60 G CM2358 K110

The QSK60 G CM2358 K110 engine also supports the Pressure Sensor 4307451. This engine variant is equipped with advanced features that enhance its operational capabilities. The sensor’s integration into this model ensures that the ECU receives accurate pressure data, which is essential for the engine’s optimal functioning, especially in demanding environments.

QST30 CM2350 T101

The QST30 CM2350 T101 engine is another model that benefits from the Pressure Sensor 4307451. This engine is designed for applications that require a balance of power and efficiency. The sensor’s role in this engine is to provide real-time pressure feedback, which helps in fine-tuning the engine’s performance and preventing potential issues.

QSV91-G4 CM558/CM700 V102

Lastly, the QSV91-G4 CM558/CM700 V102 engine is compatible with the Pressure Sensor 4307451. This engine is part of the Cummins QSV series, which is known for its versatility and reliability in various industrial applications. The sensor’s integration into this model ensures that the ECU can effectively monitor and adjust to pressure variations, thereby enhancing the engine’s overall performance and durability.

Role of Part 4307451 Pressure Sensor in Engine Systems

The Part 4307451 Pressure Sensor is integral to the precise operation and monitoring of various engine systems. Its primary function is to measure and relay pressure data to the Engine Control Module (ECM), ensuring optimal performance and efficiency.

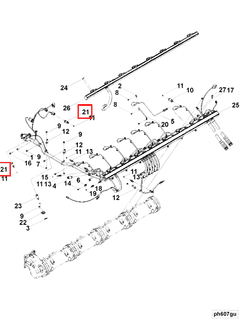

Integration with Turbocharger and Manifold

In turbocharged engines, the pressure sensor is strategically placed to monitor the pressure within the turbocharger and manifold. This data is essential for the ECM to adjust the turbocharger’s operation, maintaining the correct boost pressure. Proper pressure management prevents over-boosting, which can lead to engine damage, and under-boosting, which reduces performance.

Exhaust and Nitrogen Oxide Sensor Interaction

The pressure sensor also plays a role in the exhaust system, particularly in conjunction with the Nitrogen Oxide (NOx) sensor. By monitoring exhaust pressure, the sensor helps the ECM fine-tune fuel injection and exhaust gas recirculation (EGR) rates. This optimization reduces NOx emissions, contributing to a cleaner and more efficient combustion process.

Fuel Control and Engine Performance

Accurate pressure readings from the sensor are vital for the fuel control system. The ECM uses this data to adjust the fuel delivery, ensuring the air-fuel mixture is optimal under varying pressure conditions. This results in improved fuel efficiency and reduced emissions.

Location and Arrangement

The placement of the pressure sensor is carefully considered within the engine arrangement. Typically, it is located in areas where pressure fluctuations are most significant, such as near the turbocharger, manifold, and exhaust. This strategic location ensures that the sensor can provide real-time, accurate data to the ECM, allowing for immediate adjustments to engine parameters.

Communication with Engine Control Module

The pressure sensor communicates directly with the ECM, providing continuous pressure readings. The ECM uses this information to make split-second decisions regarding fuel delivery, turbocharger operation, and exhaust management. This dynamic interaction ensures that the engine operates within its optimal performance window, regardless of driving conditions.

Conclusion

In summary, the Cummins 4307451 Pressure Sensor is a versatile and essential component that enhances the functionality of various Cummins engine models by providing accurate pressure data to the ECU. Its compatibility with the QSK19 CM2350 K105, QSK50 CM2350 K108, QSK60 G CM2358 K110, QST30 CM2350 T101, and QSV91-G4 CM558/CM700 V102 engines ensures that these engines can operate efficiently and reliably in a wide range of applications. The sensor’s role in engine systems, including its integration with turbochargers, manifolds, and exhaust systems, highlights its importance in maintaining optimal engine performance and efficiency.

-

Dixon, J. (2010). Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning.

↩ -

Lakshminarayanan, P. A., & Nayak, N. S. (2011). Critical Component Wear in Heavy Duty Engines. John Wiley & Sons.

↩ -

Bennett, S. (2012). Modern Diesel Technology: Light Duty Diesels. Cengage Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.