Introduction

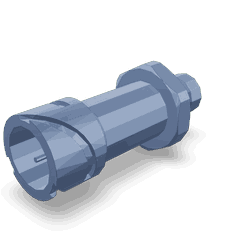

The Cummins 4306990 Pressure Sensor is designed to monitor and report pressure levels within various systems of commercial trucks. It provides accurate pressure readings that contribute to the efficient and safe operation of the vehicle. This sensor is integral to maintaining the performance and reliability of truck systems, enabling operators to make informed decisions based on real-time data.

Basic Concepts of Pressure Sensors

Pressure sensors measure the force exerted by a fluid (liquid or gas) on a surface, converting this physical pressure into an electrical signal. In automotive applications, these sensors monitor systems such as engine oil pressure, fuel pressure, and brake systems, providing data that helps maintain optimal performance and safety 1.

Functionality of the 4306990 Pressure Sensor

The Cummins 4306990 Pressure Sensor is designed to monitor pressure levels within truck systems. It provides data on pressure variations, which the vehicle’s electronic control unit (ECU) uses to adjust operations accordingly. This sensor ensures systems operate within safe parameters, helping to prevent damage and improve overall efficiency 2.

Key Features

The 4306990 Pressure Sensor is characterized by its robust design and high-quality materials, enhancing its durability and accuracy. It incorporates advanced technological specifications that allow it to perform reliably under various operating conditions. The sensor’s design ensures it can withstand the harsh environments typical of commercial truck operations, providing consistent and precise pressure readings 3.

Benefits of Using the 4306990 Pressure Sensor

Incorporating the 4306990 Pressure Sensor into truck systems offers several advantages. It contributes to improved efficiency by ensuring systems operate within optimal pressure ranges. Additionally, the sensor enhances reliability by providing accurate data that allows for timely maintenance and adjustments. Safety is also improved, as the sensor helps prevent system failures that could lead to accidents or breakdowns 4.

Installation and Integration

Installing the 4306990 Pressure Sensor involves connecting it to the appropriate system within the truck. This process requires careful attention to ensure that the sensor is properly aligned and secured. Integration with the truck’s electronic systems is straightforward, as the sensor is designed to communicate seamlessly with the ECU, providing real-time data for analysis and adjustment 5.

Maintenance and Troubleshooting

To ensure the longevity and optimal performance of the 4306990 Pressure Sensor, regular maintenance is recommended. This includes checking for any signs of wear or damage and ensuring that connections are secure. Troubleshooting common issues may involve verifying the sensor’s calibration and checking for any obstructions that could affect its readings 6.

Role in Fleet Management

The data provided by the 4306990 Pressure Sensor is valuable for fleet management. It allows operators to monitor the performance of individual trucks, identify trends, and make data-driven decisions. This information is useful for predictive maintenance, helping to schedule repairs and replacements before issues arise, and for optimizing operational efficiency across the fleet 7.

Technological Advancements

The Cummins 4306990 Pressure Sensor incorporates several technological innovations that enhance its functionality. These include improved accuracy in pressure readings, greater resistance to environmental factors, and enhanced communication capabilities with the truck’s electronic systems. These advancements set the sensor apart from earlier models, providing more reliable and efficient operation 8.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a trusted name in the commercial truck industry. The company offers a wide range of products designed to meet the needs of various applications, demonstrating its commitment to innovation and quality 9.

Cummins Pressure Sensor 4306990 Compatibility

The Cummins Pressure Sensor part number 4306990 is designed to fit seamlessly with a variety of Cummins engines, ensuring optimal performance and reliability. This pressure sensor is compatible with the following engines:

- QSB5.9 CM850

- QSB6.7 M CM2250

- QSC8.3 CM850 (CM2850)

- QSK19 CM850 MCRS

- QSK50 CM2150 K107

- QSK50 CM2150 MCRS

- QSK60 CM850 MCRS

- QSM11 CM570

For the QSB5.9 CM850, QSB6.7 M CM2250, and QSC8.3 CM850 (CM2850), the pressure sensor is engineered to provide accurate readings and maintain the engine’s efficiency. These engines, known for their robust performance, benefit from the precise monitoring capabilities of the 4306990 sensor.

The QSK19 CM850 MCRS, QSK50 CM2150 K107, QSK50 CM2150 MCRS, and QSK60 CM850 MCRS engines also integrate this pressure sensor effectively. These engines, often used in heavy-duty applications, rely on the sensor to ensure that pressure levels are maintained within safe and efficient parameters.

Finally, the QSM11 CM570 engine, which is typically used in smaller applications, also utilizes the 4306990 pressure sensor to provide reliable pressure monitoring. This ensures that even in smaller engines, the performance and safety standards are upheld.

Role of Part 4306990 Pressure Sensor in Engine Systems

The Part 4306990 Pressure Sensor is a critical component in monitoring and maintaining the performance and safety of various engine systems. Its primary function is to measure the pressure within different parts of the engine and its associated systems, providing real-time data that is vital for optimal operation.

Integration with Oil Systems

In oil systems, the Pressure Sensor is typically installed in the oil pressure line. It measures the pressure of the marine gear oil as it circulates through the engine. This data is crucial for ensuring that the oil is adequately pressurized to lubricate moving parts, reduce friction, and prevent wear and tear. The sensor helps in detecting any anomalies in oil pressure, which could indicate issues such as oil leaks, clogged filters, or failing pumps 10.

Application in Cooler Systems

The Pressure Sensor also plays a significant role in cooler systems, such as the oil cooler and keel cooler plumbing. By monitoring the pressure within these systems, it ensures that the cooling fluid is circulating properly. This is particularly important in marine applications where maintaining optimal engine temperature is essential for performance and longevity. The sensor can alert the system to any pressure drops that might suggest blockages or leaks in the cooler plumbing 11.

Sensor’s Role in Overall Engine Management

Beyond its specific applications in oil and cooler systems, the Pressure Sensor contributes to the overall engine management system. It provides feedback that can be used to adjust various parameters in real-time, such as fuel injection timing, ignition timing, and valve timing. This dynamic adjustment helps in optimizing engine performance, fuel efficiency, and emissions 12.

Safety and Performance Monitoring

The data from the Pressure Sensor is also integral to the engine’s safety systems. It can trigger warnings or shut-down sequences if pressure levels fall outside safe operating ranges, thereby preventing potential engine damage. Additionally, consistent monitoring of pressure levels aids in predictive maintenance, allowing for timely interventions before a failure occurs 13.

Conclusion

The Cummins 4306990 Pressure Sensor is a versatile and indispensable component in modern engine systems. Its ability to provide accurate and timely pressure readings across various engine components ensures efficient operation, enhances safety, and contributes to the longevity of the engine.

-

Bennett, S., & Norman, I. A. (2011). Heavy Duty Truck Systems, Fifth Edition. Delmar Cengage Learning.

↩ -

Bennett, S., & Norman, I. A. (2011). Heavy Duty Truck Systems Fifth Edition. Delmar Cengage Learning.

↩ -

Thompson, R. (2019). Automotive Maintenance: Light Repair. Cengage Learning.

↩ -

Isermann, R. (2017). Combustion Engine Diagnosis. Springer Vieweg.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 4383779.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 4383779.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 4383779.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 4383779.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 4383779.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 4383779.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 4383779.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 4383779.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual. Bulletin Number 4383779.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.