This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4011376 Position Sensor is a critical component in the engine systems of commercial trucks, designed to monitor and report the position of various engine parts. This sensor provides essential data that contributes to the efficient and reliable operation of the vehicle. By accurately detecting the position of engine components, it helps optimize engine performance and ensures smooth operation 1.

Basic Concepts of Position Sensors

Position sensors are devices that detect the position of an object and convert it into an electrical signal. These sensors are integral to many automotive systems, providing data used to control and monitor various functions. They operate based on different technologies, such as magnetic, optical, or resistive principles, and are used in applications ranging from engine management to safety systems 2.

Purpose of the Cummins 4011376 Position Sensor

This Cummins part is specifically designed to play a role in the engine management system by monitoring the position of critical components. It provides real-time data to the engine control unit (ECU), allowing for precise adjustments to be made to the engine’s operation. Its integration within the system ensures that the engine operates efficiently under varying conditions 3.

Key Features

The Cummins 4011376 Position Sensor is characterized by its robust design and high-quality materials, which ensure durability and reliability in demanding environments. It incorporates advanced technological specifications that enhance its accuracy and responsiveness. The sensor’s design allows for easy installation and integration into the engine system, minimizing downtime during maintenance procedures 4.

Benefits

The advantages provided by this part include improved engine efficiency through precise monitoring and control of engine components. It also enhances diagnostic capabilities, allowing for quicker identification and resolution of issues. Overall, this sensor contributes to the truck’s performance by ensuring that the engine operates within optimal parameters 5.

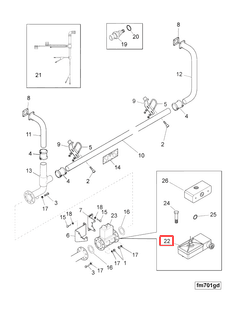

Installation and Integration

Installing the Cummins 4011376 Position Sensor involves several steps and considerations to ensure proper functionality. Preparations may include cleaning the installation area and checking for any necessary modifications to the engine system. Careful attention to the manufacturer’s guidelines ensures that the sensor is correctly positioned and securely attached, facilitating accurate readings and reliable operation 6.

Troubleshooting and Maintenance

Common issues that may arise with the Cummins 4011376 Position Sensor include inaccurate readings or sensor failure. Diagnostic procedures involve checking the sensor’s connections, inspecting for physical damage, and verifying the accuracy of its readings. Regular maintenance, such as cleaning the sensor and its surroundings, can help prevent issues and ensure optimal performance and longevity 7.

Impact on Truck Performance

The Cummins 4011376 Position Sensor influences various aspects of truck performance, including fuel efficiency, emissions, and overall reliability. By providing accurate position data, it allows the engine management system to make precise adjustments, leading to more efficient fuel consumption and reduced emissions. Its role in maintaining engine reliability ensures that the truck operates smoothly and consistently 8.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing high-quality, reliable, and innovative products. Its extensive product range caters to various applications, ensuring that customers have access to solutions that meet their specific needs 9.

Cummins Position Sensor 4011376 Compatibility

The Cummins Position Sensor part number 4011376 is designed to integrate seamlessly with a range of Cummins engines, ensuring precise monitoring and control of engine performance. This sensor is crucial for maintaining optimal engine operation by providing accurate data on the position of various engine components.

QSV81G and QSV91G Engines

The Cummins Position Sensor 4011376 is specifically engineered to fit the QSV81G and QSV91G engines. These engines are part of Cummins’ QSV series, known for their reliability and efficiency in various applications. The sensor’s design allows it to interface effectively with the electronic control systems of these engines, ensuring that the engine control unit (ECU) receives accurate positional data. This data is vital for the ECU to make real-time adjustments to engine parameters, such as fuel injection timing and air-fuel ratio, thereby enhancing overall engine performance and efficiency 10.

Role of Part 4011376 Position Sensor in Engine Systems

This part is integral to the precise operation of various engine components, ensuring optimal performance and efficiency.

- Assembly Valve Solenoid: The position sensor provides real-time data on the valve’s position, allowing the engine control unit (ECU) to make necessary adjustments for fuel delivery and ignition timing. This enhances the overall combustion process.

- Gas Module P=1,25bar and Gas Module P=1,8bar: The sensor monitors the pressure and flow of gas within the system. It ensures that the gas is delivered at the correct pressure, which is essential for maintaining consistent engine performance under varying load conditions.

- Module Fuel Control System: The position sensor provides feedback on the fuel injector’s position. This allows the ECU to fine-tune the fuel injection process, resulting in improved fuel efficiency and reduced emissions.

- Module Gas and Module P=3bar Gas Systems: The sensor’s ability to monitor gas pressure and flow rates ensures that the gas is delivered at the optimal pressure, which is vital for efficient combustion and engine performance.

- Solenoid Valve System: The position sensor ensures that the valve opens and closes at the correct times. This precise control is essential for maintaining the correct air-fuel mixture, which is critical for engine efficiency and performance.

Overall, the Cummins 4011376 Position Sensor is a key component in ensuring that these engine systems operate smoothly and efficiently.

Conclusion

The Cummins 4011376 Position Sensor plays a significant role in the engine management system of commercial trucks. By providing accurate and real-time data on the position of engine components, it enhances engine performance, fuel efficiency, and emissions control. Its robust design, ease of installation, and compatibility with various Cummins engines make it a valuable component for maintaining optimal engine operation.

-

Sully, F. K. (1998). Motor Vehicle Mechanics Textbook, Fifth Edition. Heinemann Professional Publishing.

↩ -

Arora, S., Abkenar, A. T., & Jayasi, S. G. (2021). Heavyduty Electric Vehicles: From Concept to Reality. Elsevier.

↩ -

Fijalkowski, B. T. (2011). Automotive Mechatronics Operational and Practical Issues Volume 1. Springer.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5467240.

↩ -

Sully, F. K. (1998). Motor Vehicle Mechanics Textbook, Fifth Edition. Heinemann Professional Publishing.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5467240.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5467240.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5467240.

↩ -

Cummins Inc. (n.d.). Company Overview. Retrieved from Cummins Official Website.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5467240.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.