This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

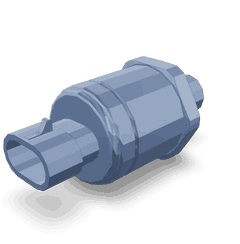

The Cummins 3408591 Pressure Sensor is designed to monitor and report pressure levels within commercial truck systems, ensuring efficient and reliable vehicle operation. By providing accurate pressure readings, it contributes to the overall performance and safety of the truck 1.

Basic Concepts of Pressure Sensors

Pressure sensors measure the force exerted by a fluid on a surface, converting this physical pressure into an electrical signal for interpretation by the vehicle’s electronic systems. In automotive applications, these sensors are crucial for engine management, brake systems, and transmission control 2.

Role of the 3408591 Pressure Sensor in Truck Operation

This Cummins part is integrated into truck systems to monitor specific pressure points, providing data essential for the engine control unit (ECU) to adjust engine operation. It ensures correct pressure levels for efficient combustion, fuel injection timing, and overall engine performance 3.

Key Features of the 3408591 Pressure Sensor

Characterized by a robust design and high-quality materials, this part ensures durability and reliability in demanding environments. Its specifications include precise measurement capabilities and resistance to environmental factors such as temperature variations and vibrations 4.

Benefits of Using the 3408591 Pressure Sensor

Utilizing this part leads to improved engine performance through accurate pressure readings, allowing for better engine management and enhanced fuel efficiency. It also aids in diagnostic processes, providing valuable data for identifying and addressing potential issues 1.

Installation and Integration

Proper installation of this part is crucial for its effective operation. It should be installed according to the manufacturer’s guidelines, ensuring secure fitting and correct connection to the truck’s electronic systems. Compatibility with the truck’s model and engine type, along with secure and contaminant-free connections, are essential for optimal performance 2.

Troubleshooting and Maintenance

Regular maintenance of this part is important for its longevity and accurate operation. This includes checking for wear or damage, ensuring secure connections, and cleaning the sensor to remove any buildup that could affect its readings. Troubleshooting may involve verifying the sensor’s readings against known values or replacing the sensor if faulty 3.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins has established a strong reputation in the commercial truck industry. The company’s product range includes various components and systems designed to enhance the performance, efficiency, and reliability of commercial vehicles 4.

Cummins Pressure Sensor 3408591 Compatibility

The Cummins Pressure Sensor 3408591 is designed to integrate seamlessly with a variety of engine models, ensuring reliable performance and accurate readings across different applications. This pressure sensor is engineered to fit within the engine systems of the following engines:

K-Series Engines

- K19

- K38

- K50

The K-Series engines, including the K19, K38, and K50, are known for their robust design and efficiency. The Pressure Sensor 3408591 is compatible with these engines, providing essential data for maintaining optimal engine performance.

M-Series Engines

- M11 CELECT PLUS

- M11 MECHANICAL

The M11 CELECT PLUS and M11 MECHANICAL engines benefit from the precise measurements offered by the Pressure Sensor 3408591. This sensor is integral to the electronic control systems of the M11 CELECT PLUS, while also providing reliable data for the mechanical systems of the M11 MECHANICAL engine.

N-Series Engines

- N14 MECHANICAL

The N14 MECHANICAL engine is another model that integrates well with the Pressure Sensor 3408591. This sensor ensures that the engine operates within the desired pressure parameters, contributing to overall engine health and longevity.

V-Series Engines

- V903

The V903 engine also utilizes the Pressure Sensor 3408591 to monitor and regulate pressure levels. This compatibility ensures that the V903 engine maintains its performance standards, providing reliable operation in various demanding conditions.

By ensuring compatibility with these diverse engine models, the Cummins Pressure Sensor 3408591 offers a versatile solution for maintaining engine efficiency and reliability across different applications.

Role of Part 3408591 Pressure Sensor in Engine Systems

This part is integral to the efficient operation of various engine systems. It works in conjunction with the Electronic Control Module (ECM) Kit to monitor and regulate fuel delivery and pressure. This sensor provides real-time data to the ECM, allowing for precise control over the Fuel Block Connection and Injector Plumbing.

In systems utilizing the Centinel Make-Up Kit and the HHP 12V VLV/ELEC Kit, the pressure sensor ensures that the fuel pressure remains within optimal ranges, enhancing engine performance and reliability. Similarly, for the HHP 24V VLV/ELEC Kit, the sensor’s accurate readings are vital for maintaining consistent fuel pressure, which is essential for the efficient operation of high-pressure fuel systems.

The sensor also plays a significant role in the N14 12V Pressure-Time Centinel Kit and the N14 24V Hardware-Pressure-Time Valve/Mounting Kit. Here, it assists in fine-tuning the pressure-time relationship, which is critical for the proper functioning of the injectors.

Additionally, the pressure sensor is connected to the Engine Control Module and the Oil Replenishing System. It helps in maintaining the correct pressure levels, which is essential for the longevity and efficiency of the engine components.

Overall, the Part 3408591 Pressure Sensor is a key component in ensuring that the engine systems operate smoothly and efficiently by providing accurate pressure readings to the control modules and facilitating precise fuel and oil management.

Conclusion

The Cummins 3408591 Pressure Sensor is a critical component in the operation of commercial truck engines, offering precise pressure readings that enhance engine performance, fuel efficiency, and reliability. Its robust design, compatibility with various engine models, and integration with key engine systems make it an essential part for maintaining the efficiency and reliability of commercial vehicles.

-

Mohamed ElSayed PE, Fundamentals of Integrated Vehicle Realization, SAE International, 2017.

↩ ↩ -

Barry Kluczyk, How to Rebuild Any Automotive Engine, CarTech, 2008.

↩ ↩ -

Michael Hilgers, Chassis and Axles, Springer Vieweg, 2023.

↩ ↩ -

Konrad Reif Ed, Gasoline Engine Management Systems and Components, Springer Vieweg, 2015.

↩ ↩

SPECIFICATIONS

BILL OF MATERIALS

| Name | Quantity | Part Number |

|---|---|---|

| O Ring Seal | 1 | 3330159 |

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.