Introduction

The Cummins 3096793 Fluid Level Sensor is a component designed to monitor fluid levels within commercial trucks. Its purpose is to provide accurate readings of fluid levels, ensuring that the truck operates efficiently and safely. This sensor is significant in the operation of commercial trucks as it helps maintain optimal fluid levels, which is vital for the performance and longevity of the vehicle.

Basic Concepts of Fluid Level Sensors

Fluid level sensors are devices that measure the amount of fluid in a system. They operate using various technologies, such as float mechanisms, capacitive sensors, or ultrasonic waves. These sensors are commonly used in automotive systems to monitor levels of engine oil, coolant, transmission fluid, and other critical fluids. By providing real-time data on fluid levels, these sensors help prevent engine damage, improve vehicle performance, and enhance safety 1.

Purpose of the Cummins 3096793 Fluid Level Sensor

The Cummins 3096793 Fluid Level Sensor plays a specific role in the operation of a truck by monitoring the levels of fluids such as engine oil or coolant. It provides precise measurements that allow the vehicle’s electronic control unit (ECU) to make informed decisions regarding the operation of the engine and other systems. This sensor ensures that fluid levels remain within the optimal range, thereby supporting the efficient and safe operation of the truck.

Key Features

The Cummins 3096793 Fluid Level Sensor is characterized by several primary features. Its design incorporates advanced technology to ensure accurate and reliable fluid level readings. The sensor is constructed using durable materials that can withstand the harsh conditions often encountered in commercial truck environments. Technological specifications include high sensitivity and fast response times, which are crucial for maintaining precise fluid levels.

Benefits of Using the Cummins 3096793 Fluid Level Sensor

Incorporating the Cummins 3096793 Fluid Level Sensor into truck systems offers several advantages. It contributes to improved efficiency by ensuring that fluid levels are maintained at optimal levels, which can enhance engine performance and fuel efficiency. Safety is also improved, as the sensor helps prevent fluid-related issues that could lead to engine damage or failure. Additionally, the sensor supports better maintenance practices by providing early warnings of low fluid levels, allowing for timely interventions 2.

Installation and Integration

Installing the Cummins 3096793 Fluid Level Sensor in a truck involves several steps and considerations. It is important to ensure that the sensor is compatible with the truck’s system and that any necessary preparations or modifications are made. The installation process typically includes connecting the sensor to the appropriate fluid reservoir and integrating it with the vehicle’s ECU. Careful attention to these steps ensures that the sensor functions correctly and provides accurate readings.

Troubleshooting Common Issues

Identifying and resolving typical problems with the Cummins 3096793 Fluid Level Sensor may involve addressing error codes or malfunctions. Common issues can include inaccurate readings, sensor failure, or connectivity problems with the ECU. Troubleshooting steps may involve checking the sensor’s connections, ensuring it is properly calibrated, and verifying that the fluid levels are within the expected range. Regular diagnostics can help identify and resolve these issues promptly.

Maintenance Tips

Regular maintenance practices are recommended to ensure the longevity and optimal performance of the Cummins 3096793 Fluid Level Sensor. This includes periodic checks of the sensor’s connections and calibration, as well as ensuring that the fluid levels are maintained within the recommended range. Cleaning the sensor and its surroundings can also help prevent buildup that might affect its accuracy. Following these maintenance tips can help extend the sensor’s lifespan and ensure reliable operation.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a key player in the automotive industry, particularly in the manufacturing of components for heavy-duty trucks. The company is known for its commitment to innovation, quality, and customer satisfaction, providing reliable and efficient solutions for a wide range of applications 3.

Cummins Fluid Level Sensor 3096793 Compatibility

The Cummins Fluid Level Sensor part number 3096793 is designed to be compatible with a range of engine models. This sensor is crucial for monitoring fluid levels, ensuring optimal engine performance and preventing potential damage due to low fluid levels.

K38 and K50 Engines

The Fluid Level Sensor 3096793 is suitable for use with the K38 and K50 engines. These engines are known for their reliability and efficiency, and the sensor ensures that the fluid levels are maintained within the recommended parameters.

QST30 CM552 and QSV81G Engines

The sensor also fits seamlessly with the QST30 CM552 and QSV81G engines. These engines benefit from the precise fluid level monitoring provided by the 3096793 sensor, which helps in maintaining the engine’s operational integrity.

QSV91G and QSW/QSV82 Engines

For the QSV91G and QSW/QSV82 engines, the Fluid Level Sensor 3096793 is an essential component. Its compatibility with these engines ensures that fluid levels are accurately monitored, contributing to the overall efficiency and longevity of the engine.

QSW73 Engine

Lastly, the QSW73 engine is also compatible with the Fluid Level Sensor 3096793. This sensor plays a vital role in ensuring that the engine operates smoothly by maintaining the correct fluid levels.

Role of Part 3096793 Fluid Level Sensor in Engine Systems

The Part 3096793 Fluid Level Sensor is an essential component that interfaces with various engine systems to ensure optimal performance and safety. Here’s how it integrates with the provided components:

Integration with Engine Control Systems

-

Engine Control Module (ECM):

- The Fluid Level Sensor sends real-time data to the ECM, allowing it to make precise adjustments to fuel injection timing, ignition timing, and other parameters based on the current fluid levels.

-

Electronic Control Engine:

- This sensor provides continuous feedback on fluid levels, enabling the electronic control engine to maintain efficient operation and prevent potential damage from low fluid conditions.

-

Electronic Engine Monitor:

- By monitoring fluid levels, the sensor helps the electronic engine monitor to display accurate readings and alerts, ensuring that operators are informed of any discrepancies in fluid levels.

Interaction with Monitoring and Operating Systems

-

Engine Monitoring System:

- The sensor’s data is vital for the engine monitoring system, offering comprehensive insights into the engine’s health and performance, facilitating proactive maintenance.

-

Engine Operating Control:

- It ensures that the engine operating control can make informed decisions, adjusting operations to maintain fluid levels within safe parameters and optimizing engine efficiency.

Coordination with Auxiliary Systems

-

Auxiliary Pump:

- The Fluid Level Sensor works in tandem with the auxiliary pump to maintain consistent fluid pressure and levels, especially in systems where fluid demand fluctuates.

-

Oil Level Assembly Sensor:

- While the oil level assembly sensor focuses on oil levels, the Fluid Level Sensor provides broader fluid management, ensuring all necessary fluids are at optimal levels.

Specific Applications and Packages

-

Railcar Installation Package:

- In railcar applications, the sensor ensures that fluid levels are maintained during transit, contributing to the reliability and safety of the railcar’s engine system.

-

Signal Electronic Device:

- The sensor interfaces with signal electronic devices to provide alerts and notifications regarding fluid levels, enhancing overall system awareness and response.

Upfit and Kit Applications

-

Cense Upfit:

- When upfitting engines with additional sensors and monitoring equipment, the Fluid Level Sensor offers essential data that enhances the upfit’s capabilities, ensuring comprehensive engine management.

-

Kit:

- Included in various engine management kits, the sensor provides a foundational layer of fluid monitoring, ensuring that all components within the kit operate efficiently and safely.

Oil Management

- Oil Tank:

- Directly connected to the oil tank, the sensor ensures that oil levels are consistently monitored, preventing issues such as engine lubrication failure and extending the lifespan of the engine.

Conclusion

The Cummins 3096793 Fluid Level Sensor is a critical component in the maintenance and operation of commercial trucks. By providing accurate and reliable fluid level readings, this part ensures that engines operate efficiently and safely. Its integration with various engine systems enhances overall performance, facilitates proactive maintenance, and contributes to the longevity of the vehicle. Regular maintenance and proper installation are essential to maximize the benefits of this sensor.

-

Martyr, A.J. (2007). Engine Testing: Theory and Practice: Third Edition. SAE International.

↩ -

Dixon, John (2014). Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning.

↩ -

ElGindy, Moustafa and ElSayegh, Zeinab (2023). Road and Off-Road Vehicle Dynamics. Springer Nature.

↩

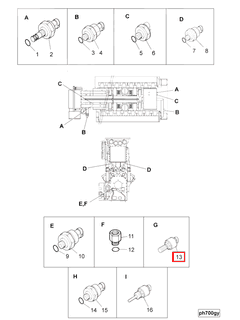

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.