2894872

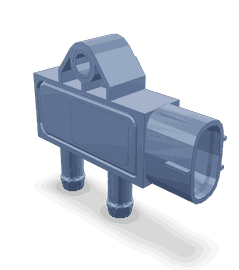

Differential Pressure Sensor

Cummins®

IN STOCK

1 is currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 2894872 Differential Pressure Sensor is designed to monitor and measure the pressure difference between two points in a system. In commercial trucks, this part plays a role in ensuring the efficient operation of various systems by providing accurate pressure readings that inform the truck’s control systems of the current state and needs of the engine and exhaust systems.

Basic Concepts of Differential Pressure Sensors

A differential pressure sensor measures the difference in pressure between two points, often referred to as the high-pressure side and the low-pressure side. These sensors operate by converting the pressure difference into an electrical signal, which can then be interpreted by the vehicle’s electronic control unit (ECU). Differential pressure sensors are utilized in various automotive applications, including engine management, emissions control, and cabin air filtration systems, to monitor and regulate system performance 1.

Role of the 2894872 Differential Pressure Sensor in Truck Operation

The Cummins 2894872 Differential Pressure Sensor is integrated into the truck’s exhaust system, where it monitors the pressure difference across the diesel particulate filter (DPF). This sensor provides data to the ECU regarding the condition of the DPF, allowing for the optimization of the regeneration process. By accurately measuring pressure differences, the sensor helps maintain the efficiency of the DPF, ensuring that it effectively captures particulate matter while minimizing backpressure on the engine 2.

Key Features of the 2894872 Differential Pressure Sensor

The Cummins 2894872 Differential Pressure Sensor is characterized by its robust design and high-quality materials, which contribute to its durability and reliability in the demanding environment of a commercial truck. The sensor incorporates advanced technology to enhance its accuracy and responsiveness, ensuring precise pressure measurements under varying operating conditions. Its design also facilitates easy installation and integration into the truck’s existing systems.

Benefits of Using the 2894872 Differential Pressure Sensor

Utilizing the Cummins 2894872 Differential Pressure Sensor offers several advantages. It contributes to improved engine performance by ensuring the DPF operates within optimal parameters, reducing the risk of engine damage due to excessive backpressure. Additionally, by maintaining the efficiency of the DPF, the sensor aids in achieving enhanced fuel efficiency and lower emissions, aligning with environmental regulations and improving the truck’s overall operational cost-effectiveness. Furthermore, the sensor’s reliable performance contributes to the overall system reliability, reducing the likelihood of unexpected downtime.

Installation and Integration

Proper installation of the Cummins 2894872 Differential Pressure Sensor is crucial for its effective operation. The installation process involves securing the sensor in the designated location within the exhaust system, ensuring it is correctly aligned and connected to the vehicle’s electrical system. Specific requirements may include the use of appropriate gaskets or seals to prevent leaks and ensure a secure fit. Integration into the truck’s system requires calibration and testing to confirm that the sensor is functioning correctly and providing accurate readings to the ECU.

Troubleshooting and Maintenance

Common issues with the Cummins 2894872 Differential Pressure Sensor may include inaccurate readings or sensor failure, often due to contamination, electrical issues, or physical damage. Troubleshooting steps involve checking the sensor’s connections, inspecting for physical damage, and cleaning or replacing the sensor if necessary. Regular maintenance practices, such as inspecting the sensor and its connections during routine service intervals, can help ensure its longevity and optimal performance.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a trusted name in the commercial truck industry, offering a wide range of products designed to meet the demanding requirements of commercial transportation. The company’s commitment to innovation, quality, and customer satisfaction is reflected in its extensive product range, including the Cummins 2894872 Differential Pressure Sensor, which exemplifies Cummins’ dedication to enhancing the performance and reliability of commercial vehicles 3.

Differential Pressure Sensor 2894872 Compatibility with Cummins Engines

The Differential Pressure Sensor 2894872, manufactured by Cummins, is designed to integrate seamlessly with a variety of Cummins engine models. This sensor plays a role in monitoring and maintaining the performance of these engines by measuring the differential pressure across various components.

Compatible Engines

- B6.7 G CMOH6.0 B125

- F4.5 CM2620 F141C

- ISD4.5 CM2220 D108

- ISF2.8 CM2220 F117

- ISF2.8 CM2220 F129

- ISF3.8 CM2220 F103

- L8.9 CM2670 L134C

- L8.9G CMOH2.0 L125B

Grouping of Compatible Engines

-

ISD and ISF Series Engines:

- ISD4.5 CM2220 D108

- ISF2.8 CM2220 F117

- ISF2.8 CM2220 F129

- ISF3.8 CM2220 F103

These engines, part of the ISD and ISF series, benefit from the precise pressure readings provided by the Differential Pressure Sensor 2894872. This sensor ensures optimal engine performance by accurately detecting pressure variations, which is essential for maintaining efficiency and preventing potential issues.

-

B and L Series Engines:

- B6.7 G CMOH6.0 B125

- F4.5 CM2620 F141C

- L8.9 CM2670 L134C

- L8.9G CMOH2.0 L125B

The B and L series engines also rely on the Differential Pressure Sensor 2894872 for critical pressure monitoring. This sensor is engineered to fit these engines, ensuring that they operate within the desired pressure parameters. The compatibility across these models highlights the versatility and reliability of the sensor in various engine configurations.

Role of Part 2894872 Differential Pressure Sensor in Engine Systems

The Part 2894872 Differential Pressure Sensor is a component in monitoring and maintaining the efficiency of various engine systems. It is particularly significant in the context of aftertreatment devices and systems.

Aftertreatment Device

In an aftertreatment device, the differential pressure sensor plays a role by measuring the pressure difference across the device. This measurement is vital for assessing the condition of the device, such as a Diesel Particulate Filter (DPF) or a Selective Catalytic Reduction (SCR) system. By continuously monitoring the pressure differential, the sensor helps in detecting any clogging or buildup within the aftertreatment device. This information allows the engine control unit (ECU) to initiate necessary maintenance actions, such as a regeneration process for the DPF, ensuring the device operates within optimal parameters.

Aftertreatment System

Within the broader aftertreatment system, which includes components like the catalytic converter and various emission control devices, the differential pressure sensor ensures that all elements are functioning correctly. The sensor’s data aids in fine-tuning the system’s performance, allowing for adjustments in fuel injection timing, exhaust gas recirculation (EGR) rates, and other parameters to maintain emissions within regulatory limits. This integration enhances the overall efficiency and longevity of the aftertreatment system.

Catalytic Converter

The catalytic converter is another component where the differential pressure sensor proves beneficial. By monitoring the pressure differential across the converter, the sensor can indicate whether the converter is experiencing any blockages or inefficiencies. This early detection allows for timely interventions, preventing potential damage to the converter and ensuring that the engine continues to operate cleanly and efficiently.

Aftertreatment Device Maintenance

Regular maintenance of aftertreatment devices is simplified with the insights provided by the differential pressure sensor. Mechanics can use the sensor’s data to schedule cleanings or replacements before significant issues arise. This proactive approach not only extends the lifespan of the aftertreatment components but also ensures consistent performance and compliance with emission standards.

Conclusion

The Cummins 2894872 Differential Pressure Sensor is integral to the effective operation and maintenance of aftertreatment devices and systems, catalytic converters, and overall engine efficiency. Its role in providing real-time data for monitoring and adjustments is indispensable in modern engine management systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.