This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

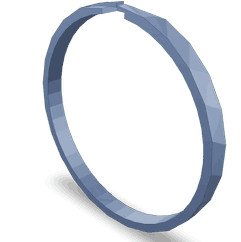

The Cummins 3521441 Split Ring Seal is a critical component designed to enhance the operational efficiency of commercial trucks. Its role is to provide a reliable seal in various mechanical systems, ensuring the integrity of the system by preventing leaks and maintaining pressure. The significance of this seal in commercial truck operations lies in its contribution to the overall performance and longevity of the vehicle’s engine or transmission system.

Basic Concepts of Split Ring Seals

Split ring seals are mechanical components used to create a seal between two surfaces. They function by being compressed between the mating surfaces, which creates a barrier that prevents the passage of fluids or gases. These seals are commonly applied in mechanical systems where dynamic sealing is required, such as in engines and transmissions. Their design allows for easy installation and removal, making them suitable for applications where maintenance access is necessary 1.

Purpose of the Cummins 3521441 Split Ring Seal

The Cummins 3521441 Split Ring Seal plays a role in the operation of a truck by ensuring a secure seal within the engine or transmission system. This seal is responsible for maintaining the integrity of the system by preventing leaks of fluids such as oil or coolant, which are vital for the lubrication and cooling of engine components. By doing so, it contributes to the efficient operation of the truck and helps in reducing the risk of system failure due to fluid loss 2.

Key Features

The primary characteristics of the Cummins 3521441 Split Ring Seal include its material composition, which is typically made from durable elastomers or rubber compounds to withstand high temperatures and pressures. Its design attributes allow for flexibility and conformity to the surfaces it seals, ensuring a tight fit. Additionally, it may possess unique properties such as resistance to chemicals and oils, which enhance its performance in harsh operating environments 3.

Benefits

The use of the Cummins 3521441 Split Ring Seal offers several advantages. It provides improved sealing efficiency, which is crucial for maintaining system pressure and preventing leaks. Its durability ensures long-term performance, even under demanding conditions. Furthermore, its resistance to wear and tear contributes to the seal’s longevity, reducing the frequency of replacements and maintenance costs.

Installation Process

Proper installation of the Cummins 3521441 Split Ring Seal involves several steps to ensure optimal performance. It requires the use of appropriate tools to avoid damage to the seal or the surfaces it contacts. Best practices include cleaning the sealing surfaces to remove any contaminants that could compromise the seal’s effectiveness. The seal should be positioned correctly within the groove or housing to ensure even compression and a secure fit.

Common Issues and Troubleshooting

Typical problems associated with split ring seals include leaks or malfunctions, which can arise from improper installation, wear and tear, or exposure to incompatible fluids. Troubleshooting methods may involve inspecting the seal for signs of damage or deformation, ensuring correct installation, and verifying compatibility with the system’s fluids and operating conditions. Addressing these issues promptly can prevent more significant problems and maintain the efficiency of the truck’s engine or transmission system.

Maintenance Tips

To prolong the lifespan of the Cummins 3521441 Split Ring Seal, routine maintenance practices are recommended. This includes regular inspection intervals to check for signs of wear or damage. Cleaning procedures should be followed to remove any buildup that could affect the seal’s performance. Replacement guidelines suggest that the seal should be replaced if it shows signs of significant wear or if it has been exposed to conditions beyond its designed tolerances.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. Its product offerings are designed to meet the demanding requirements of commercial applications, providing reliable and efficient power solutions for a variety of industries.

Cummins Engine Compatibility with Split Ring Seal Part 3521441

The Cummins Split Ring Seal part 3521441 is a crucial component designed to ensure the integrity and efficiency of various engine systems. This seal is engineered to fit seamlessly within a range of Cummins engines, providing a reliable barrier against leaks and maintaining optimal performance. Here is a detailed look at the compatibility of this seal with different Cummins engine models:

ISX Series Engines

- ISX CM570

- ISX CM870

- ISX CM871

- ISX15 CM2250 SN

The ISX series engines, known for their robust performance and reliability, utilize the Split Ring Seal part 3521441 to maintain critical sealing functions. This seal is integral in preventing oil leaks and ensuring the longevity of the engine’s internal components.

ISM Series Engines

- ISM CM570

- ISM CM570/870

- ISM CM876

- ISM11 CM876 SN

The ISM series engines, favored for their versatility and efficiency, also benefit from the Split Ring Seal part 3521441. This seal is essential in maintaining the seal integrity of these engines, contributing to their overall performance and durability.

ISBE Series Engines

- ISBE CM2150

- ISBE4 CM850

The ISBE series engines, designed for heavy-duty applications, incorporate the Split Ring Seal part 3521441 to ensure that the engine operates with minimal leakage. This seal plays a vital role in the engine’s sealing system, enhancing its operational efficiency.

ISG and ISZ Series Engines

- ISG12 CM2880 G107

- ISZ13 CM2150 Z105

The ISG and ISZ series engines, known for their adaptability and performance, utilize the Split Ring Seal part 3521441 to maintain critical sealing functions. This seal is essential in preventing leaks and ensuring the engine’s components operate efficiently.

KTA Series Engines

- KTA19GC

- KTA19GC CM558

- KTA38GC CM558

The KTA series engines, designed for high-performance applications, incorporate the Split Ring Seal part 3521441 to maintain the integrity of the engine’s sealing system. This seal is crucial in preventing leaks and ensuring the engine’s components operate efficiently.

M11 and N14 Series Engines

- M11 CELECT

- M11 CELECT PLUS

- N14 CELECT

- N14 CELECT PLUS

The M11 and N14 series engines, known for their efficiency and reliability, utilize the Split Ring Seal part 3521441 to maintain critical sealing functions. This seal is essential in preventing leaks and ensuring the engine’s components operate efficiently.

Other Cummins Engines

- 6B5.9

- G855

- G855 CM558

- GTA855 CM558 (CM2358) G101

- K19

- K38

These engines, each with their unique applications and performance characteristics, also incorporate the Split Ring Seal part 3521441. This seal is essential in maintaining the integrity of the engine’s sealing system, preventing leaks, and ensuring efficient operation.

Role of Part 3521441 Split Ring Seal in Engine Systems

The Split Ring Seal, identified by part number 3521441, is an essential component in various engine systems, ensuring optimal performance and efficiency. Its application spans across multiple assemblies and components, providing necessary sealing and support.

Aftercooler and Heat Exchanger Cores

In the aftercooler and various heat exchanger cores (such as the 52W, 55, 55W, and 60W cores), the Split Ring Seal plays a significant role. It ensures that the coolant or air passages remain sealed, preventing leaks that could degrade performance. This seal is particularly important in the assembly heat exchanger52W core and core assembly heat exchanger55, where maintaining pressure and temperature differentials is vital for efficient heat exchange.

Turbocharger Assemblies

Within the turbocharger and its related components, such as the turbocharger core and turbocharger repair kit, the Split Ring Seal is used to maintain the integrity of the sealing surfaces. It is instrumental in the turbine housing and turbine housing repair kit, where it helps in sealing the connection between the turbine and the exhaust system, ensuring that exhaust gases are directed efficiently without leakage.

Core and Housing Assemblies

The Split Ring Seal is also crucial in the core and housing assembly and various core assemblies (H3B, heat exchanger52, heat exchanger55, heat exchanger55W, and heat exchanger60W). Here, it ensures that the internal passages for fluids or gases are sealed, contributing to the overall efficiency and reliability of the system.

Connecting Rod and Upper Engine Gasket Kit

In the connecting rod and upper engine gasket kit, the Split Ring Seal provides additional support and sealing where necessary. This is particularly important in high-stress areas where precise sealing is required to maintain engine performance and longevity.

Injector and Plumbing

For the injector and injector plumbing, the Split Ring Seal ensures that fuel delivery systems remain leak-free. This is essential for maintaining the correct fuel pressure and delivery, which directly impacts engine combustion efficiency.

EBM Performance Parts and Turbocharger

In EBM performance parts and the EBM turbocharger, the Split Ring Seal is used to enhance the sealing capabilities of various connections and interfaces. This is vital for maximizing the performance gains offered by these high-performance components.

Exhaust Outlet Connection

Finally, in the exhaust outlet connection, the Split Ring Seal ensures a tight seal between the exhaust system components, preventing exhaust leaks that could lead to performance issues and increased emissions.

Overall, the Split Ring Seal (part 3521441) is a versatile component that enhances the sealing and performance of various engine systems and assemblies.

Conclusion

The Cummins 3521441 Split Ring Seal is a vital component in the maintenance and efficiency of commercial truck engines. Its role in preventing leaks, maintaining pressure, and ensuring the longevity of engine components cannot be overstated. Proper installation, regular maintenance, and prompt troubleshooting of issues are essential practices to maximize the benefits of this part. Cummins’ commitment to quality and innovation is reflected in the design and functionality of the 3521441, making it a reliable choice for commercial truck applications.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.