4982115

O Ring Seal

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4982115 O Ring Seal is a component manufactured by Cummins, designed for use in commercial trucks. This article provides an overview of the O Ring Seal, its function, key features, benefits, and maintenance suggestions.

Basic Concepts of O Ring Seals

An O Ring Seal is a type of gasket with a circular cross-section, used to create a seal between two or more parts. It is made from elastomers and is commonly used in applications requiring a reliable seal against fluids and gases. The O Ring operates by deforming slightly when compressed between two surfaces, creating a tight seal 1.

Role of the 4982115 O Ring Seal in Truck Operation

This Cummins part plays a role in ensuring the integrity of fluid systems within a truck. It is used in various applications such as fuel systems, hydraulic systems, and engine components to prevent leaks and maintain system efficiency 2.

Key Features

The 4982115 O Ring Seal features high-quality elastomer material, designed to withstand extreme temperatures and pressures. It is engineered to provide a reliable seal in demanding environments typical of commercial truck operations 3.

Benefits

The use of the 4982115 O Ring Seal offers several benefits including enhanced system reliability, reduced risk of fluid leaks, and improved overall performance of the truck’s fluid systems. Its durable construction ensures long-lasting performance even under harsh conditions 4.

Troubleshooting and Maintenance

Regular inspection of the O Ring Seal is recommended to ensure it remains in good condition. Signs of wear or damage should be addressed promptly to prevent system failures. Replacement should follow manufacturer guidelines to ensure proper fit and function .

Application in Cummins Engines

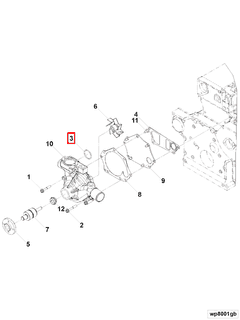

The O Ring Seal 4982115 is utilized in several Cummins engine models, including but not limited to:

-

B3.3 Series: This seal is integral to the B3.3 engine series, where it plays a vital role in sealing critical engine components. Its placement ensures that there are no leaks, which could otherwise lead to performance degradation or engine failure.

-

Other Cummins Models: While the B3.3 series is a notable application, the O Ring Seal 4982115 is also compatible with other Cummins engine models. Its design and material properties make it suitable for various sealing applications within these engines.

Importance of the O Ring Seal 4982115

This part is essential for maintaining the operational efficiency of Cummins engines. Its primary function is to provide a reliable seal in high-pressure environments, preventing the escape of fluids and gases. This seal is typically used in areas where components interface, such as between rotating shafts and stationary housings, ensuring that the engine operates smoothly and efficiently.

Compatibility and Installation

When installing the O Ring Seal 4982115, it is crucial to ensure that it is properly seated and aligned within the engine. This seal must fit snugly to provide an effective barrier against leaks. Cummins provides detailed specifications and guidelines for the installation of this seal to ensure that it meets the stringent requirements of their engines.

Maintenance and Replacement

Regular inspection of the O Ring Seal 4982115 is recommended to ensure it remains in good condition. Over time, the seal may wear out due to friction, heat, and exposure to engine fluids. If any signs of wear or damage are detected, the seal should be replaced promptly to maintain the engine’s performance and reliability.

Role of Part 4982115 O Ring Seal in Engine Systems

Long Block Assembly

In the context of a long block assembly, the O Ring Seal (part 4982115) is instrumental in ensuring the integrity of fluid pathways. It is typically positioned at the interfaces where components such as the cylinder head and engine block meet. This seal prevents coolant and oil from leaking, maintaining the efficiency and reliability of the engine’s lubrication and cooling systems.

Overhaul Kit

When included in an overhaul kit, the O Ring Seal (part 4982115) serves to replace worn or damaged seals during a comprehensive engine rebuild. Its role is to restore the seal integrity around critical components such as the oil pump, water pump, and various gasket surfaces. This ensures that the engine operates within specified parameters post-overhaul, enhancing performance and longevity.

Pump Systems

In pump systems, particularly those involving fluid dynamics such as oil and water pumps, the O Ring Seal (part 4982115) is utilized to create a tight seal around the pump housing and impeller shaft. This prevents fluid leakage and maintains the pressure integrity of the system, which is essential for efficient pump operation and overall engine performance.

Water Pump Kit

Within a water pump kit, the O Ring Seal (part 4982115) is a key component that ensures the seal between the water pump housing and the engine block is maintained. This is vital for the proper circulation of coolant through the engine, preventing overheating and ensuring consistent engine temperature regulation. The seal also helps in maintaining the structural integrity of the water pump, reducing the risk of coolant leaks that could lead to engine damage.

Conclusion

The 4982115 O Ring Seal is a critical component in the maintenance and efficiency of Cummins engines. Its role in preventing leaks, maintaining pressure, and ensuring the integrity of fluid systems is indispensable. Regular maintenance and timely replacement of this part are essential to uphold the performance and longevity of the engine.

-

Hilgers, Michael. Alternative Powertrains and Extensions to the Conventional Powertrain. Springer Nature, 2023.

↩ -

Gilles, Tim. Automotive Service: Inspection, Maintenance, Repair: 2nd Edition. Cengage Learning, 2020.

↩ -

Norman, Andrew. Diesel Technology Fundamentals Service Repair Eighth Edition. The Goodheart-Willcox Company Inc, 2016.

↩ -

Cummins Inc. Operation and Maintenance Manual for F3.8 CM2620 F149B, Bulletin Number 5660054.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.