This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3966177 O-Ring Seal is a critical component for commercial trucks, designed to ensure the integrity of fluid systems and prevent leaks. This part is essential for maintaining the performance and efficiency of trucks, especially in demanding environments.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a gasket made from a jointless ring of elastomeric material, used to create a barrier between two surfaces to prevent fluid and gas passage. These seals are valued for their simplicity, effectiveness, and versatility in mechanical systems 1.

Role of the 3966177 O-Ring Seal in Truck Operation

The Cummins 3966177 O-Ring Seal ensures the integrity of seals within truck engines and systems. It is used in areas requiring a tight seal, such as around fittings, flanges, and within the engine block, to maintain pressure and prevent leaks, thus contributing to the truck’s overall efficiency and reliability.

Key Features of the 3966177 O-Ring Seal

This Cummins part is made from high-quality elastomeric material, offering durability and resistance to a wide range of temperatures and chemicals. Its design ensures a snug fit, maximizing sealing capabilities, and its material composition allows it to withstand harsh commercial truck operation conditions.

Benefits of Using the 3966177 O-Ring Seal

Using the Cummins 3966177 O-Ring Seal provides improved sealing efficiency, reducing leak risks and maintaining system integrity. Its durability ensures longevity under demanding conditions, enhancing the reliability of truck systems. The seal’s design and material make it suitable for harsh operating environments, improving commercial truck performance.

Installation and Maintenance

Proper installation of the Cummins 3966177 O-Ring Seal is vital for its effectiveness. It should be installed according to manufacturer guidelines, with best practices including inspecting the seal for damage and ensuring mating surfaces are clean. Regular maintenance, such as periodic inspection for wear or damage, ensures the seal’s longevity and effectiveness.

Troubleshooting Common Issues

Common issues with O-Ring Seals include leaks or failure due to wear, damage, or improper installation. Diagnosing these issues involves inspecting the seal and its installation for signs of wear, damage, or misalignment. Resolving these issues may require replacing the seal or addressing underlying problems such as surface contamination or incorrect installation practices.

Compatibility and Application

The Cummins 3966177 O-Ring Seal is designed for use in Cummins engines and other commercial truck components, demonstrating its versatility and importance in maintaining system integrity. Its application within these systems highlights the seal’s role in ensuring the reliability and efficiency of commercial trucks.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. The company’s product range includes various components and systems designed to enhance the performance and reliability of commercial vehicles, underscoring the quality and reliability of the Cummins 3966177 O-Ring Seal 2.

Role of Part 3966177 O-Ring Seal in Engine Systems

The O-Ring Seal, part number 3966177, is integral to maintaining the integrity and efficiency of various engine components. It ensures a secure and leak-free connection between different parts of the fuel system, which is essential for optimal engine performance.

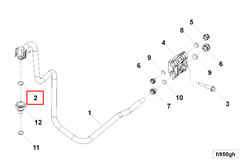

Fitting

The O-Ring Seal is used to create a tight seal between the fitting and the mating surface, preventing fuel leakage and ensuring the fuel system operates under the correct pressure and maintains efficiency. The seal also protects the fitting from contaminants that could cause wear or corrosion.

Fuel Inlet

At the fuel inlet, the O-Ring Seal prevents fuel from escaping as it enters the engine system, ensuring a consistent and uncontaminated fuel supply, which is vital for the engine’s combustion process. A reliable seal at this point also helps maintain the designed fuel pressure, contributing to smooth engine operation.

Fuel Pump Adapter

In the fuel pump adapter, the O-Ring Seal ensures a secure connection between the fuel pump and the fuel lines, maintaining the pressure required for the fuel pump to deliver fuel efficiently to the engine. A well-sealed adapter also prevents fuel vapors from escaping, which can be hazardous and affect engine performance.

Fuel Supply Tube

In the fuel supply tube, the O-Ring Seal is used at connection points to ensure fuel is delivered without leaks. This is particularly important in high-pressure fuel systems where even a small leak can lead to a significant loss of pressure and efficiency. The seal also helps protect the fuel supply tube from external elements that could cause damage or corrosion.

Pump

The O-Ring Seal is often used in the assembly of the fuel pump to ensure the internal components are well-sealed. This is essential for maintaining the pump’s efficiency and longevity. A proper seal prevents fuel from leaking out and air from entering, both of which can adversely affect the pump’s performance.

Fuel System

Overall, within the fuel system, the O-Ring Seal is a small but vital component that ensures the entire system operates under the correct conditions. It helps maintain fuel pressure, prevent leaks, and protect the system from contaminants. This contributes to the engine’s reliability, efficiency, and longevity.

Conclusion

The Cummins 3966177 O-Ring Seal plays a crucial role in the operation and maintenance of commercial trucks and engines. Its design, material composition, and application ensure the integrity and efficiency of fluid systems, contributing to the overall performance and reliability of commercial vehicles.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.