3930911

O Ring Seal

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3930911 O Ring Seal is a component designed for use in commercial truck applications. Its role is to provide a reliable seal in various systems and components, contributing to the overall integrity and efficiency of the truck’s operation. This seal is integral to preventing leaks and ensuring that systems function as intended under a range of operating conditions.

Basic Concepts of O Ring Seals

An O Ring Seal is a type of gasket that forms a seal by being compressed within a groove. It functions by creating a barrier that prevents the passage of fluids or gases. O Rings are typically made from elastomeric materials, which allow them to deform under compression and return to their original shape when the pressure is released. This elasticity is key to their sealing capability, as it ensures a tight fit within the groove and against the mating surface 1.

Purpose of the 3930911 O Ring Seal in Truck Operations

The 3930911 O Ring Seal plays a specific role in the operation of commercial trucks. It is utilized in various systems and components where sealing is required to maintain system performance. This includes applications in fuel systems, hydraulic systems, and other areas where fluid containment is necessary. The seal helps to ensure that these systems operate efficiently and without leakage, which is vital for the truck’s overall performance and safety 2.

Key Features of the 3930911 O Ring Seal

The design characteristics of the 3930911 O Ring Seal contribute to its effectiveness and durability. It is crafted from materials that offer resistance to a range of chemicals and operating temperatures, ensuring compatibility with various fluids and conditions encountered in truck operations. The dimensional specifications of the seal are precise, allowing it to fit securely within its designated groove and provide a reliable seal.

Benefits of Using the 3930911 O Ring Seal

The 3930911 O Ring Seal offers several advantages. Its design enhances sealing performance, providing a robust barrier against leaks. The material properties of the seal contribute to its resistance to wear and tear, extending its service life. Additionally, the seal’s compatibility with a variety of fluids and operating conditions makes it a versatile component for use in commercial trucks.

Installation Guidelines

Proper installation of the 3930911 O Ring Seal is important for ensuring its effectiveness. This involves preparing the mating surfaces to be clean and free of debris, which allows the seal to form a proper fit. Lubrication may be recommended to facilitate installation and reduce the risk of damage to the seal. Torque specifications, where applicable, should be followed to ensure that components are tightened to the correct level without over-compressing the seal 3.

Troubleshooting Common Issues

O Ring Seals, including the 3930911, may encounter issues such as leaks or failure over time. These problems can often be traced to installation errors, material degradation, or incompatible operating conditions. Troubleshooting methods may involve inspecting the seal and mating surfaces for damage, ensuring correct installation procedures were followed, and verifying that the seal is compatible with the fluids and temperatures in the system.

Maintenance Recommendations

Routine maintenance and inspection of the 3930911 O Ring Seal are important for ensuring optimal performance and longevity. This may include checking for signs of wear or damage during regular service intervals and replacing the seal according to manufacturer recommendations or when signs of degradation are observed. Proper maintenance helps to prevent unexpected failures and ensures the continued reliability of the truck’s systems.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history of innovation and a commitment to quality, Cummins serves the automotive, industrial, and commercial vehicle markets. The company’s product portfolio includes engines, filtration systems, and other components that are designed to meet the demanding requirements of these sectors. Cummins’ dedication to excellence is reflected in the performance and reliability of its products, including the 3930911 O Ring Seal.

Cummins O Ring Seal 3930911 Compatibility

The Cummins O Ring Seal part number 3930911 is designed to fit a variety of Cummins engines. Below is a detailed breakdown of the engines with which this seal is compatible:

ISC Series Engines

- ISC CM2150

- ISC CM554

- ISC CM850

- ISC8.3 CM2250

ISL Series Engines

- ISL CM2150

- ISL CM554

- ISL G CM2180

- ISL9 CM2150 SN

- ISL9 CM2250

- ISL9.5 CM2880 L138

L Series Engines

- L GAS PLUS CM556

- L8.9

- L8.9 CM2670 L134C

- L8.9 CM2670 L121

- L8.9G CMOH2.0 L125B

- L9 CM2670 L128B

- L9.3 L105

- L9.5 L117

G Series Engines

- 6C8.3

- C GAS PLUS CM556

- C8.3 G

- G8.3

- G8.3 CM558

- GTA8.3 CM558

QSC Series Engines

- QSC8.3 CM2880 C102

The O Ring Seal 3930911 is engineered to provide a reliable seal in various applications across these engine series, ensuring optimal performance and preventing leaks.

Role of Part 3930911 O Ring Seal in Engine Systems

The O Ring Seal, identified by part number 3930911, is a component in ensuring the integrity and efficiency of various engine systems. Its application spans across multiple components, each playing a distinct role in the overall functionality of the engine.

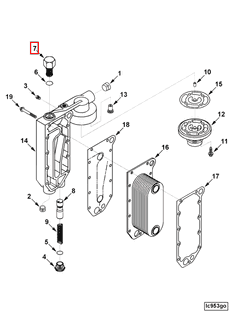

Integration with Engine Components

Cooler and Engine Oil System

In the cooler and engine oil system, the O Ring Seal is utilized to create a tight seal between the cooler and the engine oil passages. This ensures that the oil flows smoothly without any leaks, maintaining the optimal temperature of the engine oil. The seal prevents contamination and ensures that the oil retains its lubricating properties.

Engine Head and Oil Filter Cooler

When installed in the engine head and oil filter cooler, the O Ring Seal plays a significant role in maintaining the pressure within the system. It prevents any oil leakage that could lead to a drop in oil pressure, which is vital for the proper functioning of the engine components.

Lower Engine Gasket Kit and Lubricating Oil Filter Head

In the lower engine gasket kit and lubricating oil filter head, the O Ring Seal ensures that there are no gaps through which oil can escape. This is particularly important in the lubricating oil filter head, where maintaining a consistent oil flow is essential for the filtration process.

PMM Piston Upgrade and Lubricating Oil Filter Kit

For the PMM piston upgrade and lubricating oil filter kit, the O Ring Seal is used to secure the connections, ensuring that the upgraded piston operates within a sealed environment. This enhances the performance and longevity of the piston by preventing oil leaks that could cause friction and wear.

Mounting Kit and Overhaul Kit

In the mounting kit and overhaul kit, the O Ring Seal is crucial for assembling various components securely. It ensures that all connections are leak-proof, which is essential during the overhaul process to maintain the engine’s efficiency and reliability.

Retainer Plug

The O Ring Seal is also used with the retainer plug to ensure that any fluids or gases are contained within the engine system. This is important for maintaining the pressure and preventing any external contaminants from entering the engine.

Overall, the O Ring Seal (part 3930911) is a versatile component that enhances the performance and reliability of various engine systems by ensuring secure, leak-proof connections.

Conclusion

The Cummins 3930911 O Ring Seal is a critical component in the maintenance and operation of commercial trucks and engines. Its design and material properties ensure reliable sealing across a variety of applications, contributing to the efficiency and safety of truck operations. Proper installation, maintenance, and troubleshooting are essential to maximize the performance and longevity of this Cummins part.

-

Mananathan, R. (2022). Automobile Wheel Alignment and Wheel Balancing. SAE International.

↩ -

Kasab, J., & Strzelec, A. (2020). Automotive Emissions Regulations and Exhaust Aftertreatment Systems. SAE International.

↩ -

Cummins Inc. (n.d.). QSB6.7 CM2250 (174 HP and Above). Operation and Maintenance Manual, Bulletin Number 4022265.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.