3918952

O Ring Seal

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Understanding The Cummins Part #3918952 O Ring Seal: A Comprehensive Guide For Commercial Truck Professionals

Introduction To O Ring Seals

O ring seals, also known as O-rings, are indispensable components in various mechanical systems, including commercial trucks and heavy-duty engines. These circular elastomeric seals are meticulously designed to fit into grooved spaces, creating a tight seal between two or more parts. The primary function of an O ring seal is to prevent the leakage of fluids or gases, ensuring the efficiency and safety of the system. Their importance cannot be overstated, as they play a crucial role in maintaining the integrity of the engine and other mechanical systems 1.

The Role Of The Cummins Part #3918952 O Ring Seal In Truck Engines

The Cummins part #3918952 O ring seal is a critical component in the operation of commercial truck engines. This particular O ring seal is engineered to fit into specific engine components, providing a reliable seal that prevents the leakage of fluids or gases. By maintaining a tight seal, the O ring seal ensures that the engine operates efficiently and safely, reducing the risk of mechanical failure and improving overall performance. Its role is vital in ensuring that the engine components function seamlessly, contributing to the longevity and reliability of the truck 2.

How The Cummins Part #3918952 O Ring Seal Works

The Cummins part #3918952 O ring seal operates by deforming when compressed between two surfaces, creating a tight seal that prevents the leakage of fluids or gases. The O ring seal is typically crafted from a durable elastomeric material, such as nitrile rubber or silicone, which allows it to withstand high temperatures, pressures, and chemical exposure. When the O ring seal is properly installed and maintained, it provides a reliable and long-lasting seal that ensures the efficient and safe operation of the engine. The material’s resilience and flexibility are key factors in its ability to perform under demanding conditions 3.

Troubleshooting And Maintenance Of The Cummins Part #3918952 O Ring Seal

To ensure the proper operation of the Cummins part #3918952 O ring seal, it is essential to perform regular maintenance and troubleshooting. Here are some tips for maintaining and troubleshooting the O ring seal:

- Regular Inspection: Inspect the O ring seal regularly for signs of wear, damage, or deformation. If the O ring seal appears damaged or worn, it should be replaced immediately to prevent leaks or mechanical failure.

- Proper Installation: Ensure that the O ring seal is properly installed in the designated groove, with no gaps or overlaps. An improperly installed O ring seal can lead to leaks or mechanical failure.

- Cleanliness: Clean the O ring seal and the surrounding area regularly to prevent the buildup of dirt, debris, or other contaminants that can cause the O ring seal to fail.

- Prompt Replacement: If leaks or mechanical failure occur, inspect the O ring seal for signs of damage or wear. If the O ring seal appears damaged or worn, it should be replaced immediately to prevent further issues.

About Cummins

Cummins is a leading manufacturer of engines, engine components, and related technologies for commercial trucks and heavy-duty vehicles. With a commitment to innovation, quality, and customer satisfaction, Cummins has established itself as a trusted and reliable source of commercial truck parts and solutions. The Cummins part #3918952 O ring seal is just one example of the high-quality, durable, and reliable components that Cummins offers to its customers. Their reputation for excellence is built on a foundation of rigorous testing, superior craftsmanship, and a deep understanding of the needs of commercial truck professionals.

O Ring Seal 3918952 Compatibility with Cummins Engines

The O Ring Seal part number 3918952, manufactured by Cummins, is designed to fit a variety of Cummins engines. This seal is crucial for maintaining the integrity of various engine components by preventing leaks and ensuring a tight seal where necessary. Below is a detailed description of the engines with which this O Ring Seal is compatible.

Cummins B Series Engines

- B3.3

- B4.5

- B5.6

These engines, part of the B Series, are typically used in smaller applications such as generators and light-duty equipment. The O Ring Seal 3918952 is suitable for these engines due to their similar design and operational requirements.

Cummins ISB Series Engines

- ISB5.9 CM2670 B152B

- ISB5.9 CM2670 B153B

- ISB5.9 CM2880 B110

- ISB5.9 CM2880 B140

- ISB5.9 CM2880 B149

The ISB Series engines are known for their reliability and performance in medium-duty applications. The O Ring Seal 3918952 is compatible with these engines, ensuring that critical seals are maintained, which is essential for the longevity and efficiency of the engine.

Cummins ISBE Series Engines

- ISBE CM2150

- ISBE CM800

- ISBE4 CM850

These engines are typically used in heavy-duty applications, such as trucks and construction equipment. The O Ring Seal 3918952 fits these engines, providing the necessary sealing to prevent leaks and maintain performance.

Cummins QSB Series Engines

- QSB3.3 CM2150

- QSB3.3 CM2250 EC

- QSB3.9 30 CM550

- QSB4.5 CM2250 EC

- QSB4.5 CM850 (CM2850)

- QSB6.7 CM850 (CM2850)

The QSB Series engines are designed for a range of applications, from agricultural to industrial uses. The O Ring Seal 3918952 is compatible with these engines, ensuring that they operate efficiently and reliably by maintaining the necessary seals.

By understanding the compatibility of the O Ring Seal 3918952 with these various Cummins engines, users can ensure that their equipment remains in optimal condition, reducing the risk of leaks and maintaining performance.

Role of Part 3918952 O Ring Seal in Engine Systems

The Part 3918952 O Ring Seal is integral to maintaining the integrity and efficiency of various engine systems. Its application spans across multiple components, ensuring optimal performance and longevity of the engine.

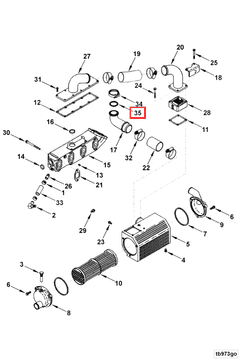

Air Intake and Transfer Connections

In the air intake connection and air transfer connection, the O Ring Seal plays a significant role in preventing air leaks. It ensures that the air entering the engine is clean and metered accurately, which is essential for combustion efficiency. Similarly, in the air crossover connection and air transfer connection, the seal maintains consistent air pressure, contributing to stable engine operation.

Turbocharger and Compressor

For the turbocharger and turbocharger compressor, the O Ring Seal is employed to secure connections and prevent oil or air leaks. This is particularly important in high-pressure environments where even minor leaks can lead to significant performance issues.

Gasket Kits

In both the complete engine gasket kit and the upper and lower engine gasket sets, the O Ring Seal complements traditional gaskets by providing additional sealing in areas where gaskets alone may not suffice. This dual-layer approach enhances the overall sealing effectiveness, reducing the risk of coolant or oil leaks.

General Connections

Across various connections within the engine, such as those in the arrangement of components, the O Ring Seal ensures that fluids and gases remain contained within their designated pathways. This containment is vital for maintaining pressure differentials and ensuring that the engine operates within its designed parameters.

Conclusion

In summary, the Part 3918952 O Ring Seal is a versatile component that enhances the functionality and reliability of multiple engine systems by providing robust sealing solutions. Regular maintenance and proper installation are crucial to ensure the efficient and safe operation of commercial truck engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.