This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3901836 O Ring Seal is a critical component designed to maintain the integrity of seals within commercial truck systems. Its role is significant in ensuring the operational efficiency and reliability of truck engines and associated systems. This seal is essential for preventing leaks and ensuring that systems operate under the correct pressure conditions.

Basic Concepts of O Ring Seals

An O Ring Seal is a type of gasket with a circular cross-section, designed to create a seal between two or more parts. Typically made from elastomers, these seals are chosen for their flexibility and ability to conform to the surfaces they seal against. The structure of an O Ring allows it to withstand pressure and maintain a seal even under dynamic conditions. Materials commonly used include nitrile rubber, silicone, and fluorocarbon, each selected based on the specific requirements of the application, such as temperature resistance and chemical compatibility 1.

Purpose of the 3901836 O Ring Seal in Truck Operation

The 3901836 O Ring Seal plays a role in the operation of commercial trucks by ensuring the integrity of seals in various systems, including fuel systems, hydraulic systems, and engine components. It is associated with specific components where maintaining a seal is crucial for performance and safety, such as injectors and fuel lines 2.

Key Features of the 3901836 O Ring Seal

The design and material characteristics of the 3901836 O Ring Seal contribute to its effectiveness and durability in truck applications. It is made from materials that offer resistance to the high temperatures and pressures found in truck engines, as well as compatibility with various fluids. Its precise dimensions ensure a snug fit in the designated applications, enhancing its sealing capabilities 3.

Benefits of Using the 3901836 O Ring Seal

The advantages provided by the 3901836 O Ring Seal include improved sealing performance, which helps in maintaining system efficiency and reducing the risk of leaks. Its durability ensures longevity, even under harsh operating conditions, contributing to the overall reliability of the truck. Additionally, its resistance to various operating conditions makes it a versatile choice for different truck systems.

Installation and Maintenance Guidelines

Proper installation techniques for the 3901836 O Ring Seal involve ensuring it is correctly seated in its groove without damage. Routine maintenance practices include regular inspections for signs of wear or damage and replacement as necessary to ensure continued effective performance. Careful handling during installation and maintenance helps preserve the integrity of the seal.

Troubleshooting Common Issues

Typical problems that may arise with O Ring Seals, including the 3901836, involve leaks due to wear, damage, or incorrect installation. Diagnosing these issues involves inspecting the seal for physical damage and ensuring it is correctly installed. Resolving these issues may require replacement of the seal or addressing other components that may be causing undue stress on the seal.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and focus on technological advancement make it a preferred choice for commercial truck operators and manufacturers.

Cummins O Ring Seal 3901836 Compatibility

The O Ring Seal part number 3901836, manufactured by Cummins, is designed to fit seamlessly within the engine systems of various Cummins engines. This part is crucial for ensuring a tight seal, preventing leaks, and maintaining optimal engine performance.

4B3.9 Engines

In the 4B3.9 engine series, the O Ring Seal 3901836 is specifically engineered to fit into critical areas where sealing is essential. Its precise dimensions and material properties ensure it can withstand the high pressures and temperatures typical of these engines. This seal is integral in maintaining the integrity of the engine’s internal components, contributing to the overall reliability and efficiency of the 4B3.9 engine.

6B5.9 Engines

Similarly, for the 6B5.9 engine series, the O Ring Seal 3901836 is a vital component. Its application in this engine series is designed to provide a robust seal in areas prone to wear and tear. The seal’s compatibility with the 6B5.9 engine ensures that it can effectively prevent leaks and maintain the engine’s operational integrity. This compatibility is crucial for the longevity and performance of the 6B5.9 engine.

Grouping of Engines

Both the 4B3.9 and 6B5.9 engines benefit from the use of the O Ring Seal 3901836, as it is designed to meet the stringent requirements of Cummins engines. The seal’s design allows it to be used across these engine series, ensuring a consistent level of performance and reliability. This grouping highlights the versatility and importance of the O Ring Seal 3901836 in maintaining the operational efficiency of Cummins engines.

Role of Part 3901836 O Ring Seal in Engine Systems

The O Ring Seal, identified as part 3901836, is instrumental in maintaining the integrity and efficiency of various engine components. Its primary function is to create a reliable seal, preventing leaks and ensuring optimal performance of the engine systems it is integrated with.

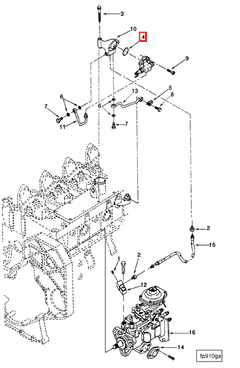

Base Fuel Pump

In the base fuel pump, the O Ring Seal is positioned to seal the connection points between the pump housing and the fuel lines. This ensures that fuel is delivered consistently without any leakage, which is essential for maintaining the correct fuel pressure and flow required for efficient engine operation.

Bosch Injection Pump

For the Bosch injection pump, the O Ring Seal is utilized at the interface between the pump body and the fuel inlet and outlet ports. This seal is vital for maintaining the precise fuel metering that the Bosch injection pump is known for. It prevents any fuel from escaping, which could otherwise lead to inconsistent fuel delivery and compromised engine performance.

Fuel Pump

In a generic fuel pump, the O Ring Seal is employed to seal the connections at the pump’s inlet and outlet. This ensures that the fuel path remains intact, allowing the pump to operate efficiently without any loss of fuel. The seal also helps in maintaining the necessary pressure levels within the fuel system.

Pump

Across various types of pumps used in engine systems, the O Ring Seal plays a similar role. It is used to seal the connections at critical points such as the pump housing, inlet, and outlet. This ensures that the pump can operate under pressure without any leaks, thereby maintaining the efficiency and reliability of the fuel delivery system.

Fuel System Components

In the broader context of the fuel system, the O Ring Seal is used in multiple components to ensure a leak-free environment. Whether it is sealing the connections in fuel lines, injectors, or other ancillary components, the seal is essential for maintaining the overall integrity of the fuel system. This helps in achieving consistent fuel delivery, which is paramount for engine performance and efficiency.

Conclusion

The Cummins 3901836 O Ring Seal is a vital component in the maintenance and operation of commercial truck engines. Its design and material properties ensure it can withstand the high pressures and temperatures typical of these engines, providing a reliable seal that prevents leaks and maintains optimal engine performance. Proper installation, maintenance, and troubleshooting are essential to ensure the continued effectiveness of this part in various engine systems.

-

Bonnick, A. (2004). A Practical Approach to Motor Vehicle Engineering and Maintenance. Elsevier.

↩ -

Kasab, J., & Strzelec, A. (2020). Automotive Emissions Regulations and Exhaust Aftertreatment Systems. SAE International.

↩ -

Giles, T. (2019). Automotive Engines Diagnosis Repair and Rebuilding. Cengage Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.