3867641

O Ring Seal

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

Minimum Quantity 6

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3867641 O Ring Seal is a component designed to ensure the integrity of seals within commercial truck systems. Its purpose is to prevent leaks and maintain system efficiency. The seal’s significance lies in its ability to contribute to the reliable operation of trucks by ensuring that fluids and gases remain contained within their designated pathways 2.

Basic Concepts of O Ring Seals

An O Ring Seal is a type of gasket made from a circular cross-section of elastomer. It functions by creating a seal between two or more parts, typically in dynamic or static applications. When compressed between flanges or in a groove, the O Ring deforms to fill any irregularities on the mating surfaces, thus preventing the passage of fluids or gases. This mechanism is fundamental in various mechanical systems to maintain pressure and prevent contamination 1.

Role of the 3867641 O Ring Seal in Truck Operation

The 3867641 O Ring Seal plays a specific role in the operation of a truck by ensuring the sealing integrity of certain systems or components. It is commonly associated with fuel systems, where it helps to maintain the pressure and purity of the fuel supply. Additionally, it may be used in other systems where fluid or gas containment is necessary to ensure optimal performance and safety 2.

Key Features of the 3867641 O Ring Seal

The 3867641 O Ring Seal is characterized by several key features that make it suitable for its intended use. These include its material composition, which is typically a durable elastomer capable of withstanding a range of temperatures and chemical exposures. Its dimensions are precisely engineered to fit specific applications, and its design ensures it can accommodate dynamic movements without losing its sealing properties 2.

Benefits of Using the 3867641 O Ring Seal

Utilizing the 3867641 O Ring Seal offers several advantages. It provides improved sealing efficiency, which helps in maintaining system pressure and preventing leaks. Its durability ensures a longer service life, reducing the frequency of replacements. Additionally, the seal’s resistance to various operating conditions, including temperature fluctuations and exposure to chemicals, enhances its reliability in demanding environments 2.

Installation and Maintenance Guidelines

Proper installation of the 3867641 O Ring Seal is vital to ensure optimal performance. It should be lubricated before installation to facilitate easy placement and to prevent damage to the seal. During maintenance, it is important to inspect the seal for signs of wear or degradation. If any issues are detected, the seal should be replaced to maintain system integrity 2.

Troubleshooting Common Issues

Common problems with O Ring Seals, such as leaks or failures, can often be traced back to improper installation, degradation due to environmental factors, or mechanical stress. Troubleshooting steps may include checking the seal for physical damage, ensuring it is the correct size and material for the application, and verifying that it is properly seated within its groove 2.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a history of innovation and a commitment to quality, Cummins has established a strong reputation in the commercial truck industry. The company’s product range is designed to meet the demanding requirements of various applications, ensuring reliability and performance 3.

Compatibility with Cummins Engines

The O Ring Seal part number 3867641, manufactured by Cummins, is a critical component designed to ensure a tight seal in various engine applications. This seal is engineered to fit seamlessly within the engine systems, providing essential sealing capabilities that prevent leaks and maintain system integrity.

Compatible Cummins Engines

The O Ring Seal 3867641 is compatible with a wide range of Cummins engines, including:

- B5.9 GAS PLUS CM556

- C GAS PLUS CM556

- ISB CM850

- ISC CM2150

- ISC CM554

- ISC CM850

- ISC8.3 CM2250

- ISL CM2150

- ISL CM554

- ISL G CM2180

- ISL9 CM2150 SN

- ISL9 CM2250

- ISM CM570

- ISM11 CM876 SN

- ISX CM570

- ISX CM870

- ISX CM871

- ISX12 CM2350 X102

- ISX12/ISX11.9 CM2250

- ISX15 CM2250

- ISX15 CM2250 SN

- ISX15 CM2350 X101

- ISZ13 CM2150 Z105

- K19

- L GAS PLUS CM556

This seal is designed to fit snugly within the specified engine models, ensuring optimal performance and reliability. Its compatibility with such a diverse range of engines underscores its versatility and importance in maintaining engine efficiency and longevity 3.

Role of Part 3867641 O Ring Seal in Engine Systems

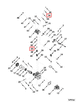

The Part 3867641 O Ring Seal is integral to ensuring the efficient and reliable operation of various engine components. Its primary function is to create a secure seal, preventing leaks and maintaining system integrity. Here’s how it interfaces with specific components:

Fuel System Components

- AFC Auto Fuel Pump: The O ring seal ensures that the fuel pump maintains a tight seal, preventing fuel leaks and ensuring consistent fuel delivery.

- Gear Fuel Pump: Similarly, in gear fuel pumps, the O ring seal is vital for maintaining pressure and preventing fuel from escaping, which is essential for engine performance.

- Fuel Pump & Calibration Code: When integrating calibration codes with fuel pumps, the O ring seal ensures that the calibration settings are not compromised by leaks.

- Fuel Pump Hardware and Head: These components rely on the O ring seal to maintain the structural integrity of the fuel system, ensuring that fuel is delivered under the correct pressure.

- Integrated Fuel System Module Kit and Service/Repair Kit: During installation or repair of these modules, the O ring seal plays a key role in ensuring that the module functions correctly without leaks.

Pressure Regulation

- Pressure Assembly Regulator and Pressure Regulator Valve: The O ring seal is used in these components to maintain consistent pressure levels within the fuel system, which is crucial for engine efficiency.

- Pump Code CPL 103, CPL-28, and CPL-57: These pump codes often incorporate O ring seals to ensure that the specified pressure settings are maintained without any loss of fuel.

Air and Emission Systems

- Air Assembly and Crankcase Breather: In these systems, the O ring seal helps in maintaining the correct air-fuel mixture and preventing the escape of harmful emissions.

- Combustion Leak Tester: Ensures that the tester can accurately detect leaks without any interference from external factors.

Performance and Modification Components

- Performance Parts and Torque Modification: In high-performance setups, the O ring seal ensures that modifications, such as torque-modifying valves, function correctly without leaks, thereby enhancing engine performance.

- Torque Modifying Valve: Seals are essential here to maintain the precise adjustments made to the engine’s torque output.

Additional Systems

- AFC-VS/Road Speed and Non AFC-VS/TMD: These systems benefit from the O ring seal by ensuring that speed and performance data are accurately recorded without any system leaks.

- XPI JV Components and Upfit Kit: These advanced components require precise sealing to function correctly, and the O ring seal plays a significant role in this regard.

- Reg. (Regulator): Ensures that the regulator maintains consistent performance without any leaks affecting its operation.

Conclusion

In summary, the Part 3867641 O Ring Seal is a fundamental component across various engine systems, ensuring that each part operates efficiently and reliably. Its role in preventing leaks, maintaining system integrity, and enhancing engine performance underscores its importance in the operation of commercial trucks 23.

-

R Mananathan, Automobile Wheel Alignment and Wheel Balancing, SAE International, 2022.

↩ -

Douglas R Carroll, Energy Efficiency of Vehicles, SAE International, 2020.

↩ ↩ ↩ ↩ ↩ ↩ ↩ -

Shashank Arora, Alireza Tashakori Abkenar, and Shantha Gamini Jayasi, Heavyduty Electric Vehicles: From Concept to Reality, Elsevier, 2021.

↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.