This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3417976 O-Ring Seal is a component designed for use in heavy-duty truck maintenance and operation. Its purpose is to provide a reliable seal in various applications within the truck’s system, ensuring the integrity of fluid systems and preventing leaks. The significance of this O-Ring Seal lies in its ability to maintain system efficiency and reliability under demanding operational conditions.

Basic Concepts of O-Ring Seals

An O-Ring Seal is a type of gasket with a circular cross-section, designed to create a seal between two or more parts. It functions by being compressed within a groove, forming a barrier that prevents the passage of fluids or gases. O-Ring Seals are widely used in mechanical systems due to their simplicity, effectiveness, and versatility in sealing applications 1.

Purpose of the 3417976 O-Ring Seal in Truck Operation

This Cummins part plays a specific role in the operation of a truck by ensuring the integrity of seals in various fluid systems. Its location within the truck’s system can vary, but it is commonly found in applications where fluid containment is critical. The function of this O-Ring Seal is to prevent leaks, maintain system pressure, and ensure the efficient operation of the truck’s components.

Key Features of the 3417976 O-Ring Seal

The design and material characteristics of the 3417976 O-Ring Seal make it suitable for its intended application. It is crafted from materials that offer durability and resistance to a range of substances, including oils, fuels, and chemicals. The O-Ring Seal is also designed to operate within a specific temperature range, ensuring reliable performance under varying conditions.

Benefits of Using the 3417976 O-Ring Seal

The advantages provided by the 3417976 O-Ring Seal include improved sealing efficiency, which contributes to the overall reliability of the truck’s system. Its longevity ensures that replacements are less frequent, reducing maintenance costs and downtime. Additionally, the seal’s ability to withstand harsh conditions enhances the truck’s operational efficiency and safety.

Installation Considerations

Proper installation of the 3417976 O-Ring Seal is crucial for ensuring optimal performance and longevity. Guidelines for installation include ensuring the groove is clean and free of debris, using the correct lubrication during installation, and avoiding over-stretching the O-Ring. These best practices help to maintain the integrity of the seal and prevent premature failure.

Troubleshooting Common Issues

Common problems associated with O-Ring Seals include leaks, extrusion, and degradation. Diagnosing these issues involves inspecting the seal for signs of wear, checking for proper installation, and assessing the condition of the groove. Resolving these issues may require replacing the O-Ring Seal, ensuring that the new seal is correctly installed to prevent recurrence.

Maintenance Tips

Regular maintenance of the 3417976 O-Ring Seal includes periodic inspection for signs of wear or damage. Care practices to prolong its service life involve keeping the seal and its environment clean, avoiding exposure to incompatible substances, and replacing the seal according to the manufacturer’s recommendations or when signs of degradation are observed.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration systems, and related technologies. With a history of innovation and a commitment to quality, Cummins has established a strong reputation in the automotive and heavy-duty truck industry. The company’s product range is designed to meet the demanding requirements of various applications, ensuring reliability and performance.

Cummins Engine O-Ring Seal 3417976 Compatibility

The O-Ring Seal part number 3417976, manufactured by Cummins, is a critical component designed to ensure a tight seal in various engine applications. This seal is engineered to fit seamlessly within the engine’s architecture, providing essential sealing properties that prevent leaks and maintain system integrity.

Compatibility with 15N CM2380 M104B, 6B5.9, 6C8.3, ISM CM570, ISM11 CM876 SN, ISX12 G CM2180 EJ, ISX12/ISX11.9 CM2250, ISZ13 CM2150 Z105

The O-Ring Seal 3417976 is compatible with the following engines:

- 15N CM2380 M104B

- 6B5.9

- 6C8.3

- ISM CM570

- ISM11 CM876 SN

- ISX12 G CM2180 EJ

- ISX12/ISX11.9 CM2250

- ISZ13 CM2150 Z105

These engines, while differing in their specific configurations and applications, share common sealing requirements that the O-Ring Seal 3417976 effectively meets. The seal’s design ensures it can handle the pressures and environmental conditions these engines operate under, providing a reliable barrier against fluid leaks.

Compatibility with QSB5.9 CM850, QSC8.3 CM850(CM2850), QSM11 CM570, QSZ13 CM2150 Z102

The O-Ring Seal 3417976 is also compatible with the following engines:

- QSB5.9 CM850

- QSC8.3 CM850(CM2850)

- QSM11 CM570

- QSZ13 CM2150 Z102

These engines, like the previous group, benefit from the O-Ring Seal’s ability to create a secure seal. The seal’s material and design are tailored to withstand the unique demands of these engines, ensuring longevity and performance.

Compatibility with Z14 CM2670 Z103B

The O-Ring Seal 3417976 is also suitable for the following engine:

- Z14 CM2670 Z103B

This engine, with its specific design and operational parameters, is another beneficiary of the O-Ring Seal’s sealing capabilities. The seal’s precision fit and durability make it an ideal choice for maintaining the engine’s efficiency and reliability.

By ensuring a tight seal, the O-Ring Seal 3417976 plays a crucial role in the overall performance and longevity of these engines, providing peace of mind to operators and maintaining the integrity of the engine systems.

Role of Part 3417976 O-Ring Seal in Various Engine Systems

The part 3417976 O-Ring Seal is integral to ensuring the efficient and reliable operation of several engine components. Its application spans across a variety of systems, each benefiting from the seal’s ability to prevent leaks and maintain pressure integrity.

Air Compressor

In the air compressor system, the O-Ring Seal is employed to create a tight seal between moving parts and stationary components. This ensures that compressed air does not escape, maintaining the system’s efficiency and preventing potential damage from air leaks.

Compressor Coolant Arrangement

Within the compressor coolant arrangement, the O-Ring Seal plays a significant role in sealing connections between the coolant passages. This is vital for maintaining the coolant’s flow and temperature, which is essential for the compressor’s optimal performance and longevity.

Compressor Coolant Plumbing

The O-Ring Seal is utilized in the compressor coolant plumbing to seal fittings and connections. This prevents coolant leaks, ensuring that the cooling system operates effectively to dissipate heat from the compressor.

Exhaust Recirculation

In exhaust recirculation systems, the O-Ring Seal is used to seal the connections in the recirculation path. This helps in maintaining the integrity of the recirculated exhaust gases, ensuring they are properly directed back into the combustion process to reduce emissions.

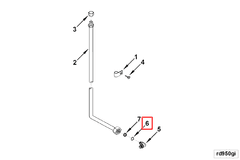

Male Adapter Elbow and Male Union

For male adapter elbows and male unions, the O-Ring Seal is critical in creating a secure connection between different sections of piping or components. This seal prevents fluid or gas leaks, ensuring the system’s efficiency and safety.

Marine Gear Oil Cooler Plumbing

In marine gear oil cooler plumbing, the O-Ring Seal is employed to seal connections within the oil cooling system. This ensures that the oil remains within the system, maintaining the cooling efficiency and protecting the gear system from overheating.

Oil Sump Pump

The O-Ring Seal is used in oil sump pumps to seal the pump’s connections and housing. This prevents oil leaks, ensuring the pump can effectively remove oil from the sump and maintain the engine’s lubrication system.

Product Installation Package

Within product installation packages, the O-Ring Seal is included to ensure that all connections made during the installation process are leak-proof. This is essential for the initial setup and long-term operation of the engine system.

Remote Oil Drain

For remote oil drain systems, the O-Ring Seal is used to seal the drain connections. This ensures that oil is properly contained within the system until it is intentionally drained, preventing spills and maintaining environmental safety.

Turbocharger Arrangement

In turbocharger arrangements, the O-Ring Seal is utilized to seal connections within the turbocharger system. This ensures that the pressurized air from the turbocharger is effectively delivered to the engine, enhancing performance and efficiency.

Conclusion

The Cummins 3417976 O-Ring Seal is a vital component in maintaining the efficiency and reliability of heavy-duty truck engines. Its role in preventing leaks, maintaining system pressure, and ensuring the integrity of fluid systems cannot be overstated. Proper installation, regular maintenance, and understanding its compatibility with various engine models are key to maximizing the benefits of this part. By ensuring a tight seal across a range of engine systems, the 3417976 O-Ring Seal contributes significantly to the overall performance and longevity of the engines it serves.

-

Ribbens, W. B. (2003). Understanding Automotive Electronics. Elsevier Science.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.